Matte manufacturing solution of solar energy single crystal silicon wafers and its preparation method

A single crystal silicon wafer and texturing liquid technology, which is applied in the field of texturing liquid for solar monocrystalline silicon wafers and its preparation, can solve problems such as explosion, environmental pollution, toxicity, etc. The effect of increasing wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

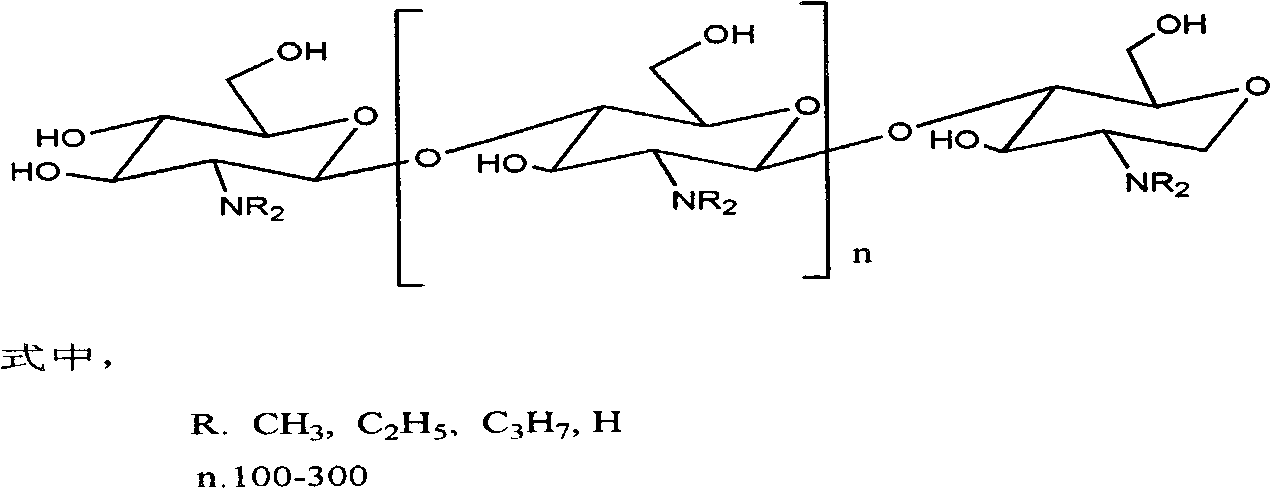

[0029] First add 85g of 18 megohm water into the solvent preparation device, add 2g of triethanolamine, 2.5g of tetramethylammonium hydroxide (TMAH), 8g of R as CH 3 Surfactant (manufacturer of surfactant is Guangxi Baise Yuanshan Co., Ltd., grade is industrial grade.), 2.5g sodium silicate, stir for 35 minutes, make it dissolve completely under 25 ℃, after filtering with 200 mesh filter screen The clear liquid is the velvet making liquid.

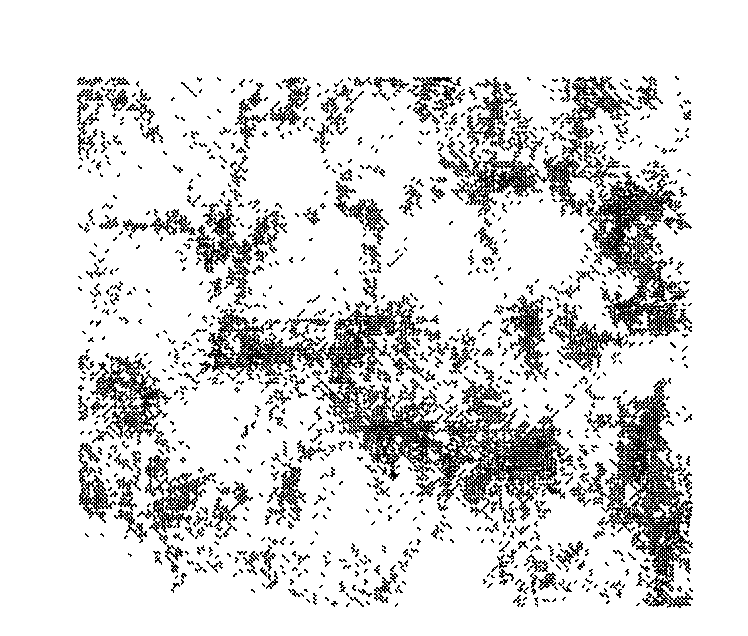

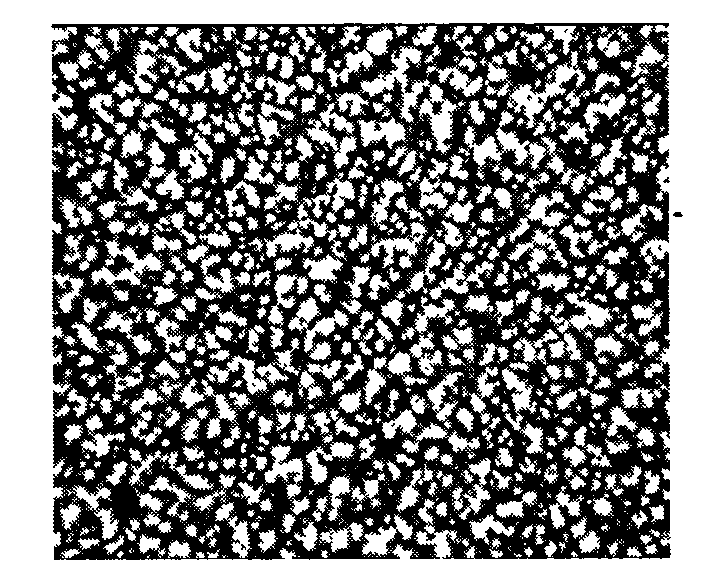

[0030] Take P-type (100) Czochralski solar monocrystalline silicon wafers for surface cleaning, put them into a plastic reactor filled with texturing liquid for chemical corrosion (surface texturing is also called surface texturing), and control the texture of texturing. The temperature is 80°C, take it out after 25 minutes of reaction, wash with 18 megohm water, and finish the texture. The texture of the texture obtained after texture is as follows: figure 1 and figure 2 As shown, it can be seen from the figure that a pyramid suede str...

Embodiment 2

[0033] First add 80.0g of 18 megohm water into the solvent preparation device, add 5.0g of triethanolamine, 2.0g of tetramethylammonium hydroxide (TMAH), 10.0g of R as C 2 h 5 Surfactant, 3g of sodium silicate, stirred for 25 minutes, completely dissolved at 15°C, filtered through a 200-mesh filter to obtain the finished texturing solution.

[0034] Take a P-type (100) Czochralski solar monocrystalline silicon wafer for surface cleaning, put it into the texturing solution prepared by the above method, react at a temperature of 90°C for 25 minutes, take it out, wash it with 18 megohm water, and finish the texturing .

Embodiment 3

[0036] First add 90g of 18 megohm water into the solvent preparation device, add 1g of triethanolamine, 2.0g of tetramethylammonium hydroxide (TMAH), 2g of surfactant whose R is H, and 5g of sodium silicate while stirring, and stir for 35 minutes, 5 Dissolve it completely at ℃, and filter through a 200-mesh filter to obtain the finished texturing liquid.

[0037] Take a P-type (100) Czochralski solar monocrystalline silicon wafer for surface cleaning, put it into the texturing solution prepared by the above method, react at a temperature of 70°C for 20 minutes, take it out, wash it with 18 megohm water, and finish the texturing .

[0038] Table 1

[0039] Test items

[0040] Table 1 is a comparison of the uniformity of the size of the pyramids on the solar monocrystalline silicon wafer in Example 1, Example 2, and Example 3, whether the pyramids cover the entire surface, and the height range of the pyramids. From the comparison of Example 1, Example 2, and Example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com