Garlic oil microcapsule with shell made of soybean protein isolate and chitosan and preparation method and application thereof

The technology of soybean protein isolate and chitosan is applied in the field of garlic oil microcapsules and its preparation, which can solve the problems of toxicity of coating raw materials, unsuitable for food industry adoption, and no garlic oil microcapsules are found, and achieves good degradability, Good biocompatibility, life-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

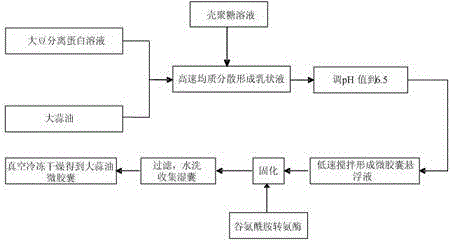

[0034] The production process of the garlic oil microcapsule preparation method of the present invention is shown in figure 1 , soy protein isolate and chitosan attract each other through static electricity to form the wall material of the microcapsule, and garlic oil is used as the core material.

[0035] First, prepare the aqueous solution of soybean protein isolate: suspend 4 g of soybean protein isolate in 100 mL of distilled water, treat at 50 °C and 500 W ultrasonic power for 5 min, centrifuge at 5000 r / min for 10 min, remove insoluble matter, and distill the supernatant to 100 mL with distilled water. That is, a 2.67% (w / v) soy protein isolate solution was obtained.

[0036] Then prepare 2% (w / v) chitosan solution with 1% (w / v) acetic acid solution as solvent.

[0037] The 2.67% soy protein isolate solution was diluted to the desired concentration with distilled water and the 2% (w / v) chitosan solution was diluted to the desired concentration with 1% (w / v) acetic acid ...

Embodiment 2

[0042] In this example, 2.67% soy protein isolate solution was diluted to 2.4% (w / v), and 2% (w / v) chitosan solution was diluted to 0.6% with 1% (w / v) acetic acid solution (w / v).

[0043] 1.2g, 0.6g and 0.3g of commercially available garlic oil were added to 3 parts of 40mL of the 2.4% (w / v) soy protein isolate solution, and then mixed with 3 parts of 40mL of the 0.6% (w / v) ) chitosan solution, and stirred the mixture at 6000r / min for 5min at 45°C to form a uniform emulsion; then added 10% (w / v) NaOH solution dropwise to adjust the pH value to 6.5, and at 45°C to Stir at 100r / min for 10min to form a microcapsule suspension; keep the temperature at 45°C, then use 10% (w / v) HCl solution to adjust the pH value of the microcapsule suspension to 6.0, add 18U of transglutaminase, and stir at a low speed (60r / v) min) for 1 hour to solidify the microcapsules, let stand to separate layers, filter and wash with water to collect the wet capsules, and vacuum freeze-dry to obtain solid mi...

Embodiment 3

[0045] In this example, 2.67% soy protein isolate solution was diluted to 2.4% (w / v), and 2% (w / v) chitosan solution was diluted to 0.6% with 1% (w / v) acetic acid solution (w / v).

[0046] The mixture was prepared by adding 0.6 g of commercially available garlic oil to 40 mL of the 2.4% (w / v) soy protein isolate solution and then mixing it with 40 mL of the 0.6% (w / v) chitosan solution. 2 parts of liquid, at 35 DEG C, stir the mixed liquid with 4000 and 8000r / min respectively for 5min to form a uniform emulsion, and other processing conditions are the same as in Example 2. Under the process conditions, the microcapsule efficiency and yield were 53.32% and 58.83%, 54.66% and 58.38%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com