Alkaline phosphatase micro-/nano-particle and preparation method thereof

A phosphatase nano- and micro-particle technology, which is applied in the fields of pharmaceutical formulations, medical preparations containing active ingredients, metabolic diseases, etc., can solve the problems of patients' pain, cumbersome operation, etc., and achieve good dispersion performance and small particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

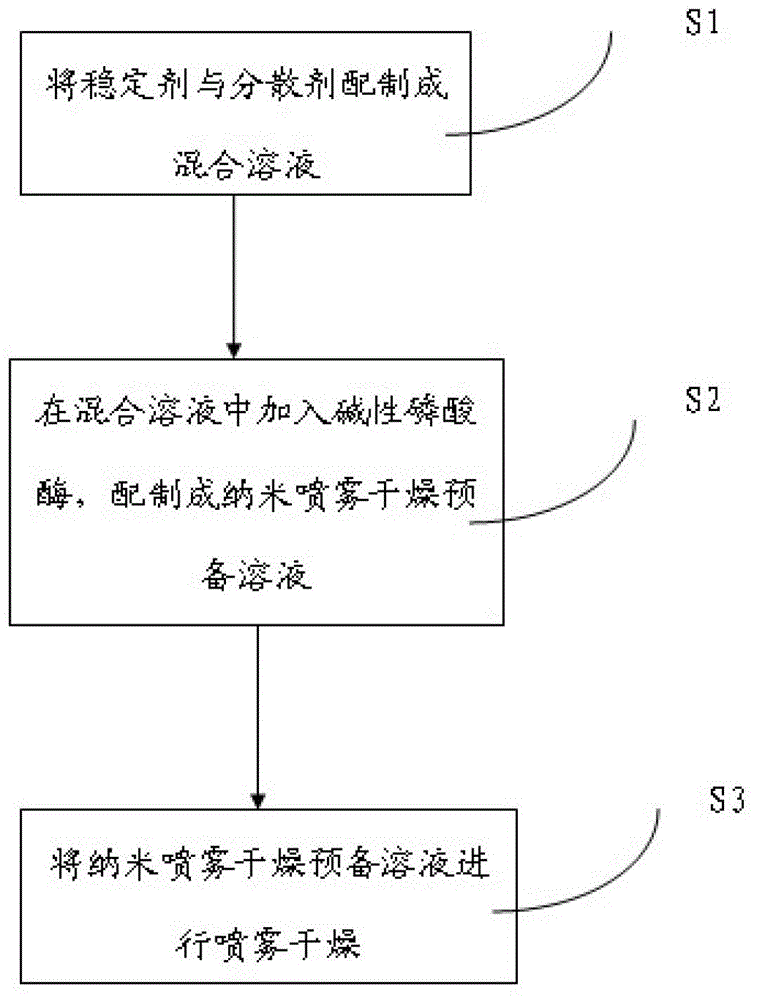

[0030] The present invention also discloses a preparation method for preparing the above-mentioned alkaline phosphatase nanoparticles, such as figure 1 shown, including the following steps,

[0031] S1: Mix the stabilizer and dispersant in a certain proportion, stir and dissolve, and prepare a mixed solution;

[0032] S2: adding a certain proportion of alkaline phosphatase to the mixed solution prepared in step S1, stirring and dissolving, fully mixing, and preparing a nano-spray drying preparation solution;

[0033] S3: Spray-dry the nano-spray drying preparatory solution obtained in step S2 by using nano-spray drying technology.

[0034] Preferably, in step S1, the mass ratio of the stabilizer to the dispersant is 1:100-100:1.

[0035] Preferably, in step S2, the mass ratio of the stabilizer, dispersant and alkaline phosphatase is 1:100-100:1.

[0036] Preferably, in step S2, the concentration of the obtained nano-spray drying preparation solution is 1×10 −5 ~ 100 g / mL.

...

Embodiment 1

[0040] Weigh 0.60 g of β-cyclodextrin and 0.10 g of alkaline phosphatase into 100 mL of ultrapure water, stir in an ice bath until completely dissolved, and filter through a filter membrane with a pore size of 0.45 μm to obtain a nano spray drying preparation solution. Then the obtained nano-spray drying preparation solution is subjected to nano-spray drying, and the process parameters of nano-spray drying are set as follows: the inlet temperature of the spray drying cylinder is 100°C, the spray rate is 100%, the feed rate mode is 1, and the gas flow rate is 130L / min, spray cap aperture 4μm.

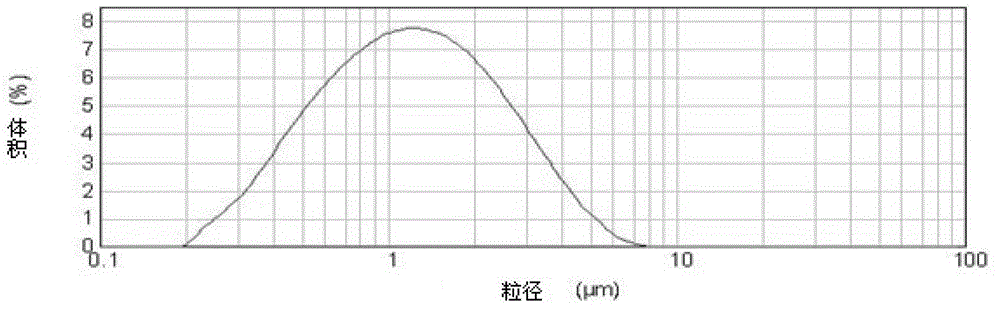

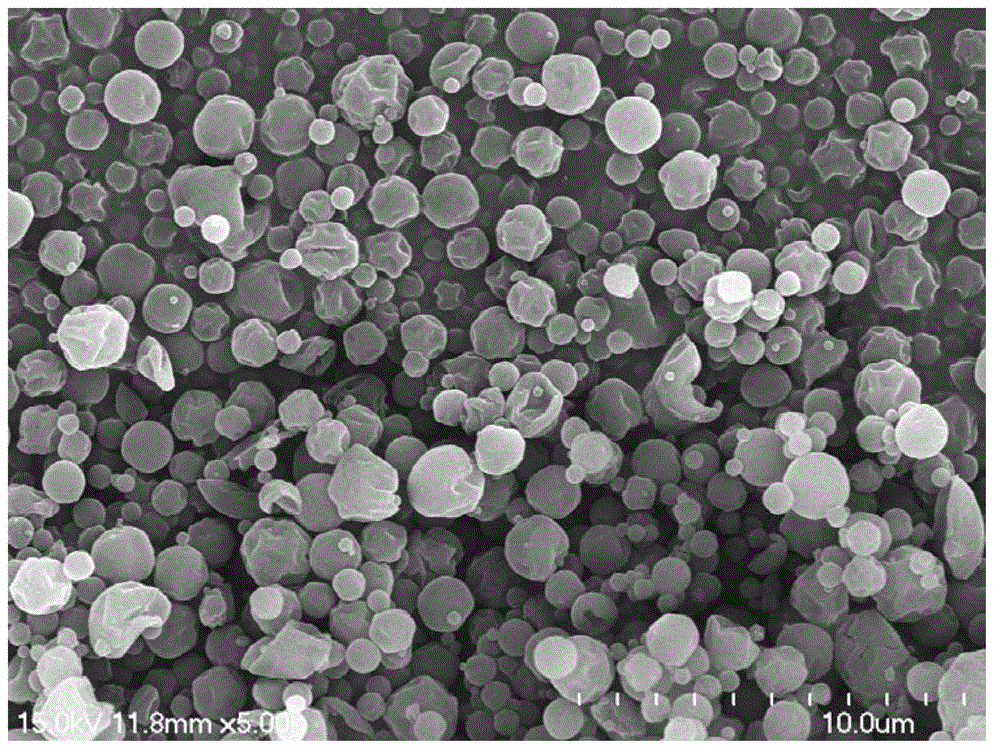

[0041] The detection and characterization results of the alkaline phosphatase nanoparticle produced by the above process: the yield of alkaline phosphatase nanoparticle is 75%; the enzyme activity retention rate is 65%; 90% of the particle size distribution is 0.40-3.50 μm; scanning electron microscope observation shows that the average particle size distribution is about 2 μm, and the ...

Embodiment 2

[0043] Weigh 0.33g of β-cyclodextrin, 0.27g of L-leucine and 0.10g of alkaline phosphatase into 100mL of ultrapure water, stir in an ice bath until completely dissolved, and filter through a filter membrane with a pore size of 0.45μm to obtain a nano-spray drying preparation solution. Then the obtained nano-spray drying preparation solution is subjected to nano-spray drying, and the process parameters of nano-spray drying are set as follows: the inlet temperature of the spray drying cylinder is 100°C, the spray rate is 100%, the feed rate mode is 1, and the gas flow rate is 130L / min, spray cap aperture 4μm.

[0044] The detection and characterization results of the alkaline phosphatase nanoparticles prepared by the above process: the yield rate is 68%; the enzyme activity retention rate is 95%; The particle size distribution is about 1 μm, and the shape is smooth and wrinkled spheres; the in vitro lung deposition efficiency is 86%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com