Method for extracting and separating L-valine from fermentation liquor by employing membrane separation and electroosmosis combined technology

A technology of fermented liquid and valine, which is applied in the field of extraction and separation of L-valine, which can solve the problems of incomplete decolorization of activated carbon, broken resin structure, and increased number of resin regeneration, so as to reduce the decolorization process of activated carbon and impurities and the effects of pigment content reduction, yield and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

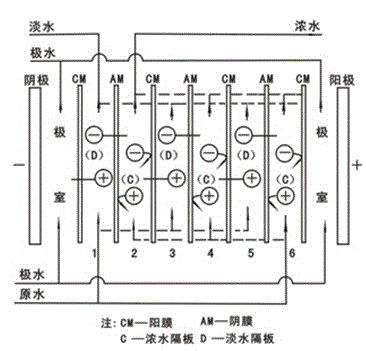

[0030] 4.2L of L-valine fermentation broth was filtered through ultrafiltration membrane with a molecular weight cut-off of 200,000 to remove bacteria. The operating pressure was 0.3MPa, the temperature was 30°C, and the amount of dialysis water was 1L. The filtrate completely removed the bacteria. Then, through a 6L combined electrodialysis membrane equipment at a temperature of 30°C, L-valine demineralized clear liquid was obtained. The demineralized clear liquid is filtered through a nanofiltration membrane with a molecular weight cut-off of 500 to remove impurities such as small molecular proteins and pigments. The operating pressure is 1.2MPa, the temperature is 30°C, and the dialysis water volume is 3.2L, and then pre-concentrated by RO reverse osmosis membrane. The results are shown in the table below:

[0031] Electrodialysis electrically driven membrane separator: the conductivity of the original solution: 33200μS / cm

[0032] Conductivity of demineralized clear liquid: 10...

Embodiment 2

[0037] The 330L L-valine fermentation broth was filtered through an ultrafiltration membrane with a molecular weight cut-off of 800,000 to remove the bacteria. The operating pressure was 0.35MPa, the temperature was 30°C, and the dialysis water volume was 100L. The filtrate completely removed the bacteria. Then through a 500L combined electrodialysis membrane equipment at a temperature of 30°C, a demineralized L-valine clear liquid is obtained. The demineralized clear liquid is filtered through a nanofiltration membrane with a molecular weight cutoff of 500 to remove impurities such as small molecular proteins and pigments. The operating pressure is 1.2MPa, the temperature is 30°C, and the dialysis water volume is 245L, and then pre-concentrated through the RO reverse osmosis membrane. The results are shown in the table below:

[0038] Electrodialysis electrically driven membrane separator: the conductivity of the original solution: 34200μS / cm

[0039] Conductivity of demineralize...

Embodiment 3

[0044] L-valine fermentation broth 4.6M 3 The bacteria are removed by ultrafiltration membrane with a molecular weight cut-off of 800,000. The operating pressure is 0.4MPa, the temperature is 30°C, and the dialysis water volume is 1.5 M. 3 . The filtrate completely removes the bacteria, and then passes 8M 3 The combined electrodialysis membrane equipment, the temperature is 30 ℃, to obtain the demineralized L-valine clear liquid. The demineralized clear liquid is filtered through a nanofiltration membrane with a molecular weight cut-off of 1000 to remove impurities such as small molecular proteins and pigments. The operating pressure is 1.2MPa, the temperature is 30°C, and the dialysis water volume is 3.6 M. 3 , And then pre-concentrated through RO reverse osmosis membrane. The results are shown in the table below:

[0045] Electrodialysis electrically driven membrane separator: the conductivity of the original solution: 33400μS / cm

[0046] Conductivity of demineralized clear liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com