Gasification method of organic wastes and special gasification furnace

A technology of organic waste and gasification furnace, which is applied in the manufacture of combustible gas and petroleum industry, etc. It can solve the problems of high cost of gasification furnace, extremely unstable gasification, narrow adaptability, etc., and achieve gas volume reduction and heat increase The effect of reducing the effect and safe use of gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

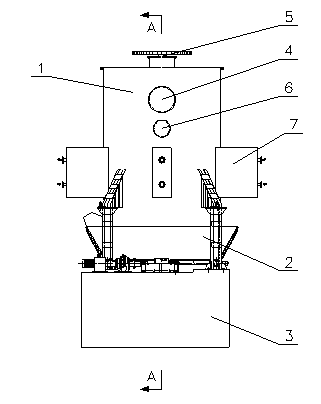

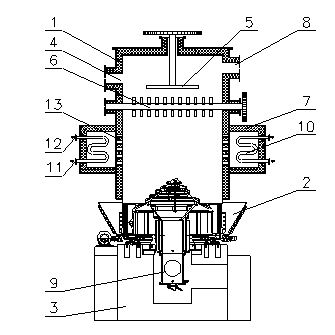

[0042] Such as figure 1 and 2 As shown, a special gasifier for organic waste includes a furnace body 1 and a slagging device 2 , and the furnace body 1 is fixedly installed on a base 3 .

[0043] The feed inlet 4 and the gas outlet 8 are provided on the upper part of the furnace body 1 .

[0044] The top in the body of heater 1 is vertically provided with a vertical stirring rod 5, and the rotating shaft of the vertical stirring rod 5 is arranged through the top of the furnace body 1, and the vertical stirring rod 5 is in-line.

[0045] A horizontal stirring rod 6 is arranged horizontally in the furnace body 1, and the horizontal stirring rod 6 is arranged below the feed inlet 4 and the gas outlet 8. Tooth shape.

[0046] The side wall of the furnace body 1 is provided with 4 indirect heating devices evenly distributed along the circumferential direction.

[0047] The indirect heat device includes a heating chamber 7 in the shape of a box. A gas radiant tube heater 10 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com