Preparation method of glass rod surface micro-lens array

A technology of microlens array and glass rod, which is applied to photoengraving process of pattern surface, lens, process for producing decorative surface effect, etc., can solve the problems of fixed structure parameters, high processing cost, low processing efficiency, etc. To achieve the effect of simple preparation process, adjustable size and large adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment includes the following steps:

[0024] Step 1, selecting a glass rod with a diameter of 3 mm for preparing a microlens array, the glass rod being K9 glass with a polished surface;

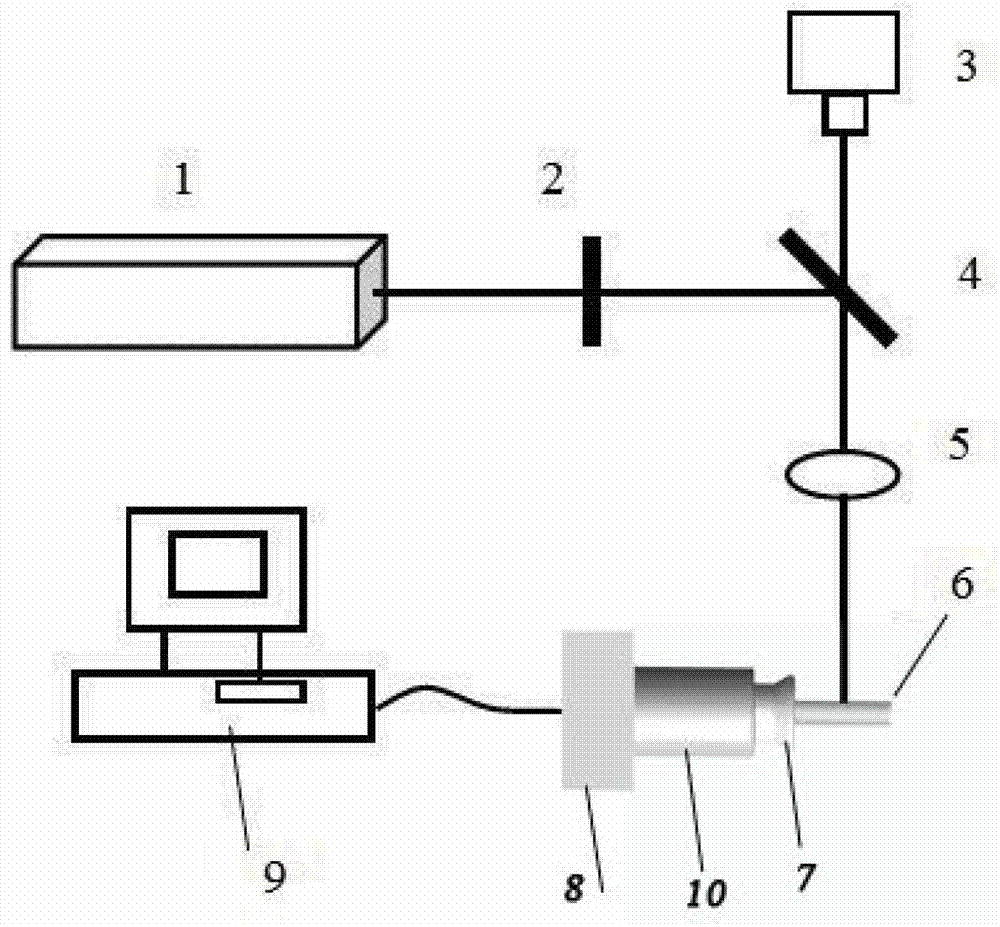

[0025] Step 2, fix the glass rod 6 on the fixture 7, fix the fixture 7 on the rotating shaft 10, and fix the other end of the rotating shaft 10 on the three-dimensional precision displacement platform 8, the computer 9 and the three-dimensional precision displacement platform 8 and the rotating shaft 10 Connected to control the movement of the two, the laser emitted by laser 1, the laser parameters are pulse width 30fs, wavelength 800nm, single pulse energy 3μJ, repetition frequency 1KHz, through the controllable switch 2, mirror 4, and then through The objective lens 5 with a numerical aperture value of 0.7 is focused on the surface of the glass rod 6, and the CCD camera 3 monitors the entire processing process;

[0026] Step 3. According to the processing requirements, con...

Embodiment 2

[0032] Step 1, selecting a glass rod with a diameter of 2 mm for preparing a microlens array, the glass rod being K9 glass with a polished surface;

[0033] Step 2, fix the glass rod 6 on the fixture 7, fix the fixture 7 on the rotating shaft 10, and fix the other end of the rotating shaft 10 on the three-dimensional precision displacement platform 8, the computer 9 and the three-dimensional precision displacement platform 8 and the rotating shaft 10 Connected to control the movement of the two, the laser emitted by laser 1, the laser parameters are pulse width of 80fs, wavelength of 400nm, single pulse energy of 1μJ, repetition frequency of 1KHz, through the controllable switch 2, mirror 4, and then through The objective lens 5 with a numerical aperture value of 0.3 is focused on the surface of the glass rod 6, and the CCD camera 3 monitors the entire processing process;

[0034] Step 3: Control the rotation of the rotating shaft 10 and the movement of the three-dimensional p...

Embodiment 3

[0039] Step 1, selecting a glass rod 6 with a diameter of 10 mm for preparing a microlens array, the glass rod being quartz glass with a polished surface;

[0040] Step 2, fix the glass rod 6 on the fixture 7, fix the fixture 7 on the rotating shaft 10, and fix the other end of the rotating shaft 10 on the three-dimensional precision displacement platform 8, the computer 9 and the three-dimensional precision displacement platform 8 and the rotating shaft 10 Connected to control the movement of the two, the laser emitted by laser 1, the laser parameters are pulse width 30fs, wavelength 800nm, single pulse energy 5μJ, repetition frequency 10KHz, through the controllable switch 2, mirror 4, and then through The objective lens 5 with a numerical aperture value of 0.5 is focused on the surface of the glass rod 6, and the CCD camera 3 monitors the entire processing process;

[0041] Step 3. According to the processing requirements, control the rotation of the rotating shaft 10 and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com