Complexing-adsorption refining process for lubricating oil base oil

A lubricating oil base oil, adsorption refining technology, applied in the direction of lubricating composition, only multi-stage serial refining process, etc., can solve the problem of lower base oil yield, shortened service life of filter cloth, engineering investment and process operation The problem of high cost can solve the problem of poor stability of lubricating base oil, improvement of oxidation stability, and improvement of oxidation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

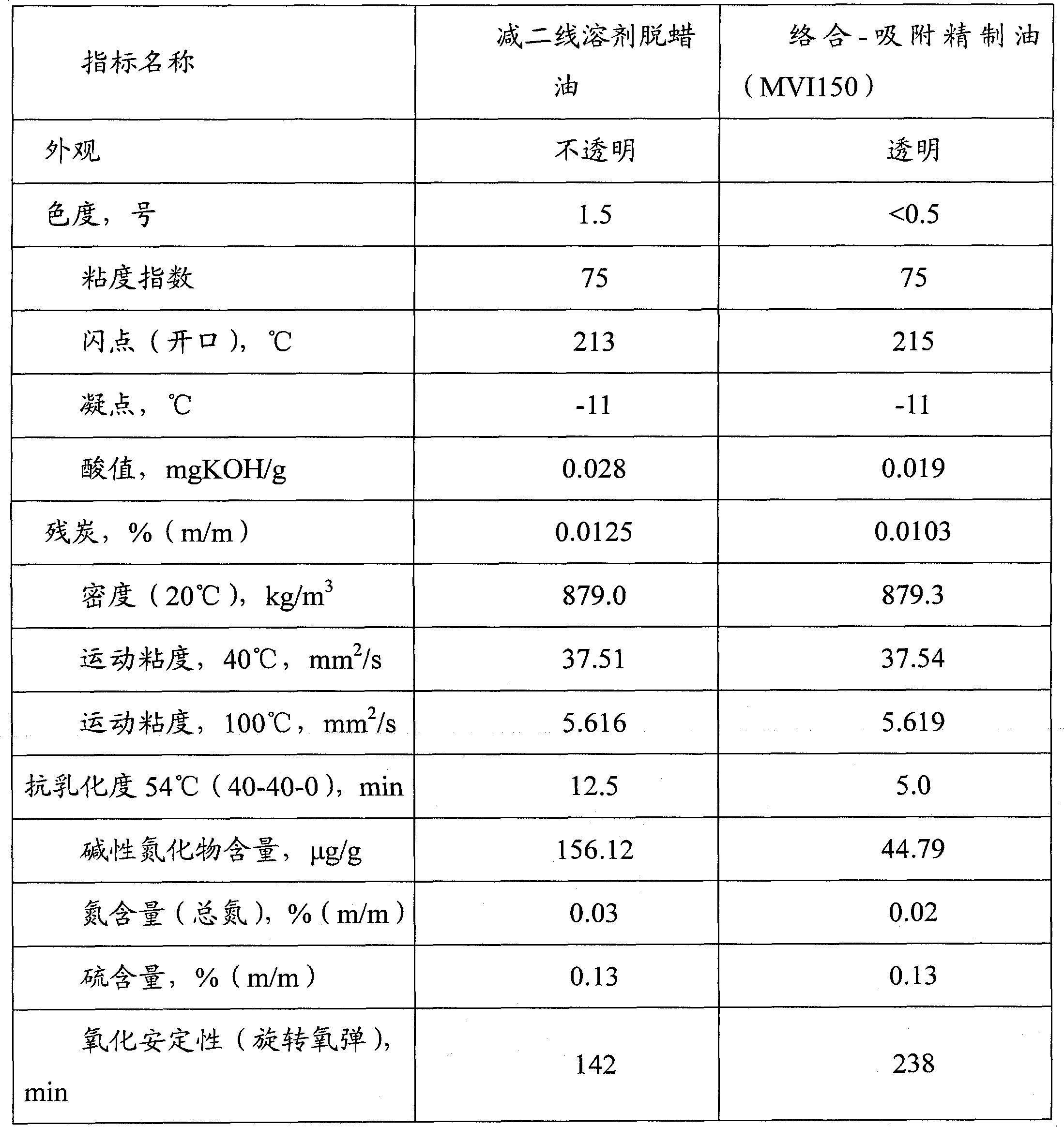

Embodiment 1

[0040] 1), dewaxed oil (its properties are as shown in Table 1) and complexed refining agent (15% aminotriacetic acid, 65% 1-butyl-3-methylimidazole tetrafluoroethylene) of Lanzhou Petrochemical Co., Ltd. Borate, 15% ethylene glycol, 5% hydroxymethyl cellulose) are premixed, and the addition of the complexing refining agent is 0.3% of the quality of Lanzhou Petrochemical minus the second-line solvent dewaxed oil;

[0041] 2) After fully stirring and mixing at a temperature of 80-90°C for 30 minutes, stand at a temperature of 80-90°C for heat preservation, and settle naturally by gravity for 2 hours, and the tailings of the complex will settle at the bottom of the settling tank;

[0042] 3), take out complexation refined oil from the upper part of the settling tank, add adsorbent (mass percentage: ZnO: 21%; Al 2 o 3 : 68%; SiO 2 : 3%; P 2 o 5 : 2%; MoO 3 : 2.5%; WO 3 : 2%; GeO 2 : 1.5%), the amount of adsorbent added is 0.4% of the quality of Lanzhou Petrochemical’s seco...

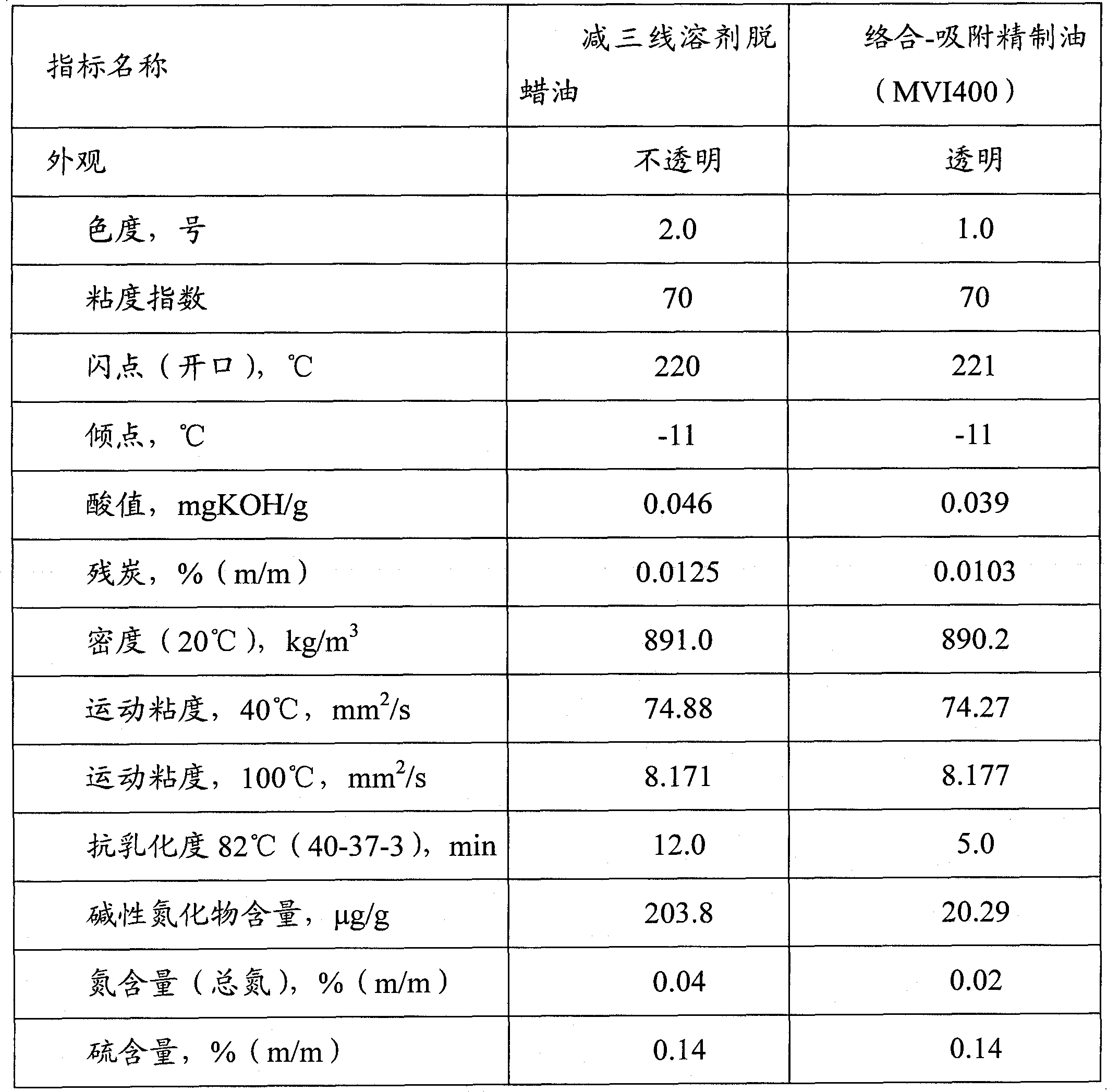

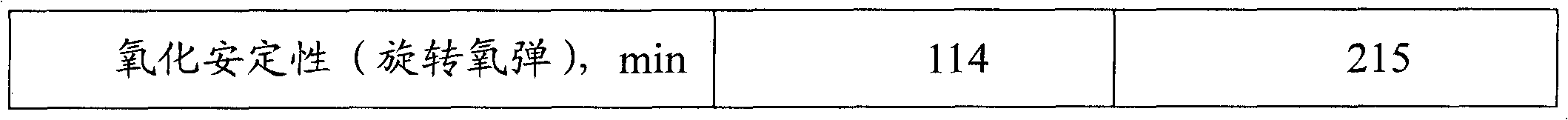

Embodiment 2

[0052] 1), the dewaxed oil of Lanzhou Petrochemical minus third-line solvent (its properties are as shown in Table 2) and complexed refined preparation (mass percentage is 15% aminodiacetic acid, 70% 1-butyl-3-methylimidazole tetrafluoro Borate, 12% ethylene glycol, 3% polyacrylamide) are premixed, and the addition of the complexing refining agent is 0.4% of the quality of Lanzhou Petrochemical minus the third-line solvent dewaxed oil;

[0053] 2) After fully stirring and mixing at a temperature of 80-90°C for 30 minutes, stand at a temperature of 80-90°C for heat preservation, and settle naturally by gravity for 2 hours, and the tailings of the complex will settle at the bottom of the settling tank;

[0054] 3), take out complexation refined oil from the upper part of the settling tank, add adsorbent (mass percentage: ZnO: 21%; Al 2 o 3 : 68%; SiO 2 : 3%; P 2 o 5 : 2%; MoO 3 : 2.5%; WO 3 : 2%; GeO 2 : 1.5%), the amount of adsorbent added is 0.6% of the quality of Lanzh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com