Novel chitosan used for lithium ion cell and derivative water-based binder of chitosan

A lithium-ion battery and binder technology, applied in the field of new chitosan and its derivatives water-based binder, can solve the problems of air pollution, inability to effectively suppress the volume of Si particles, flammability and explosion, and achieve Wide range of sources, improved battery cycle performance, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

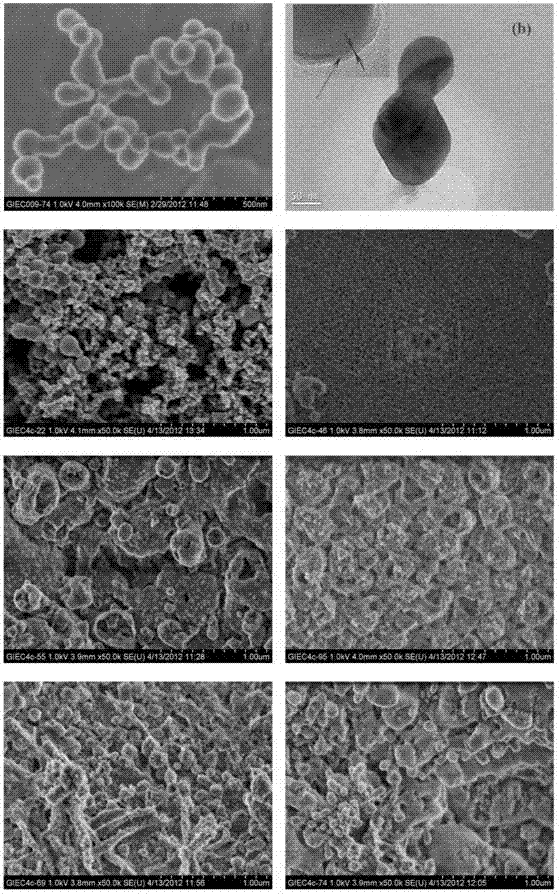

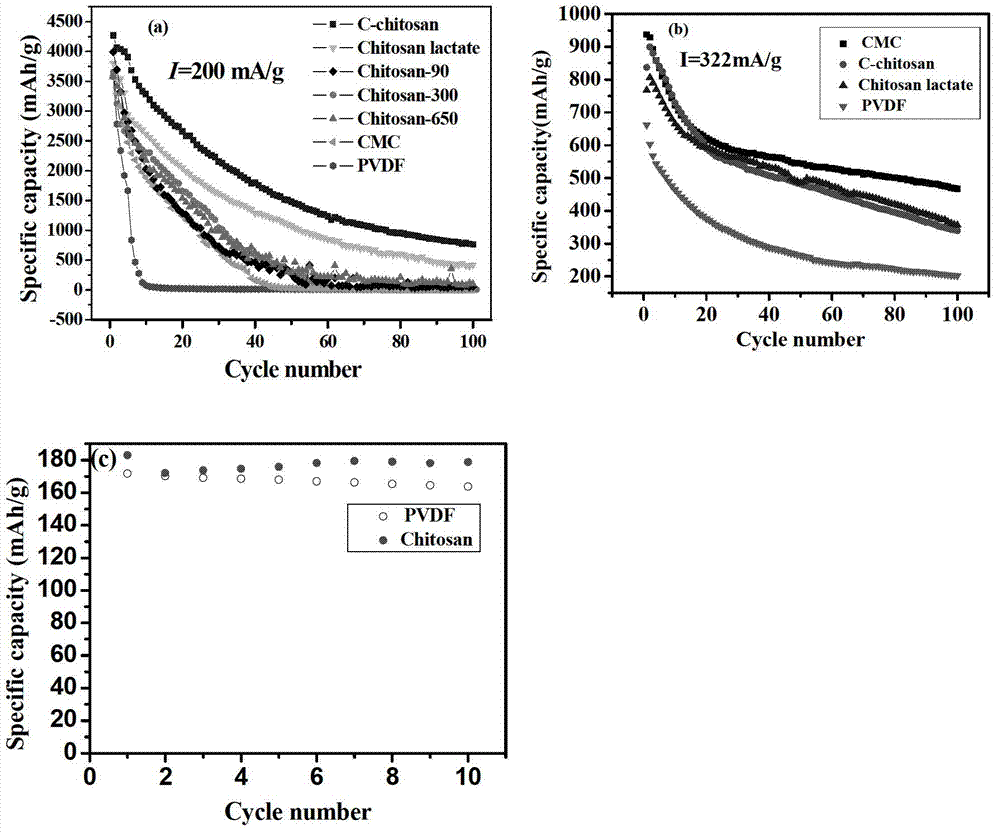

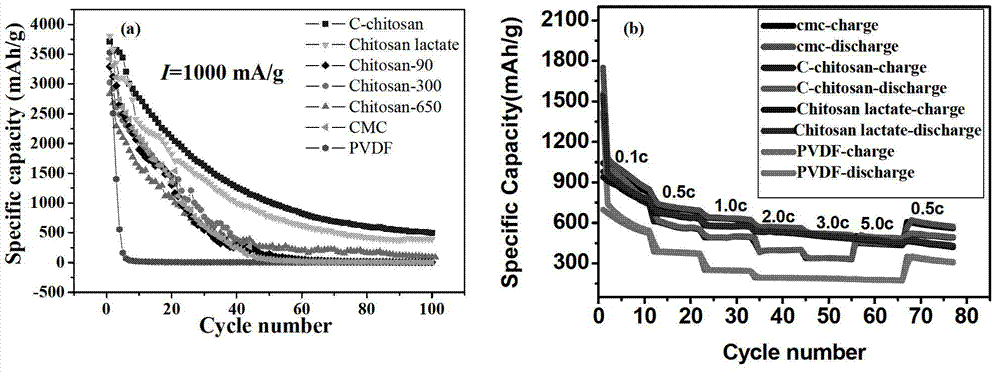

Embodiment 1

[0029] First, the viscosity of 90cps chitosan is configured into a 5wt% aqueous solution containing 1% acetic acid. Weigh 80mg of nano-Si and 38.7mg of acetylene black in a mortar, grind for 10 minutes, and then add 0.2064g of 5% chitosan aqueous solution dropwise. Grind for 5 minutes until the binder is evenly mixed with Si powder and carbon powder, then add 1mL of deionized water dropwise, and then fully grind for 15-10 minutes. Pour the pasty mixture onto the Cu sheet, spread it evenly with a 100 μm spatula, quickly place it in a blast drying oven at 70°C, and take it out after five minutes. Then put the electrode piece into a vacuum drying oven, and dry it in vacuum at a constant temperature of 90° C. for 6 hours. After weighing the vacuum-dried electrode pieces, assemble them in the glove box in the 2025 battery case, use the lithium sheet as the counter electrode, use the polyethylene film as the separator, and use 1MLiPF 6 EC / DMC / DEC (v / v / v=1 / 1) conduct constant curre...

Embodiment 2

[0031] The difference from example 1 is that the chitosan with a viscosity of 300cps is used as the binding agent.

Embodiment 3

[0033] Different from example 1 is to utilize the chitosan that viscosity is 650cps as binding agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com