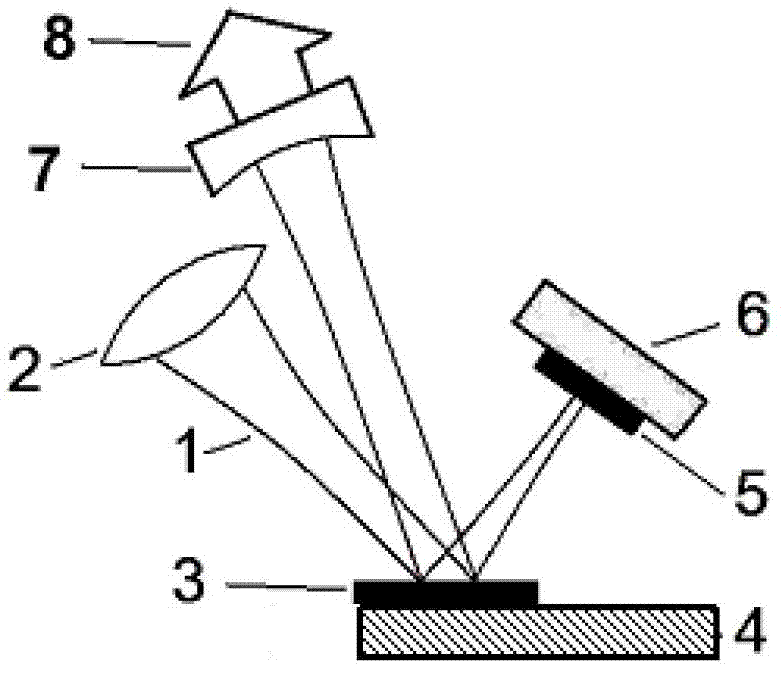

Graphene mode-locked optically pumped thin disc semiconductor laser

A semiconductor and graphene technology, applied in the field of graphene mode-locked optically pumped thin-film semiconductor lasers, achieves the effects of short saturable recovery time, simple structure, and narrow output pulse width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

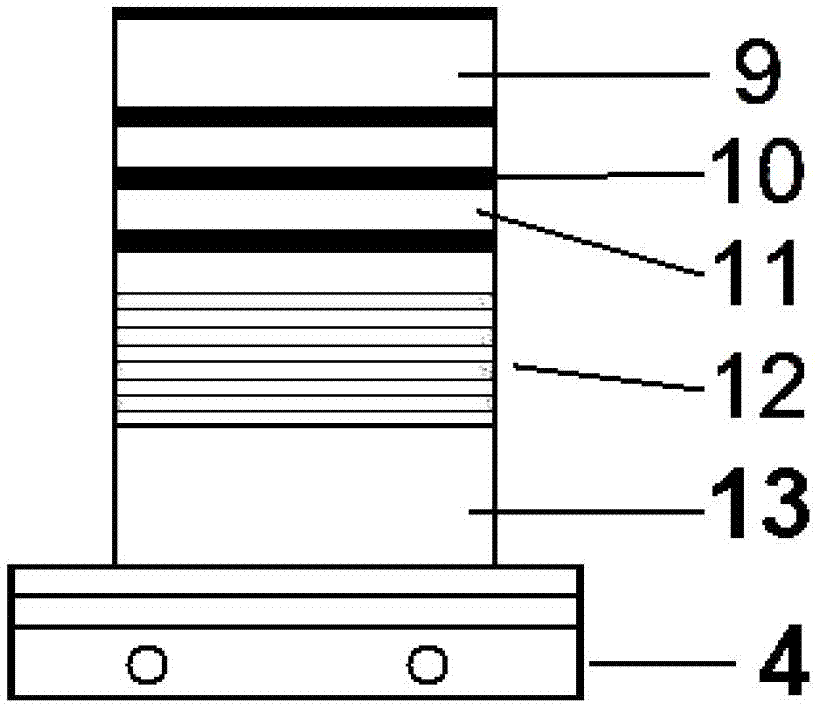

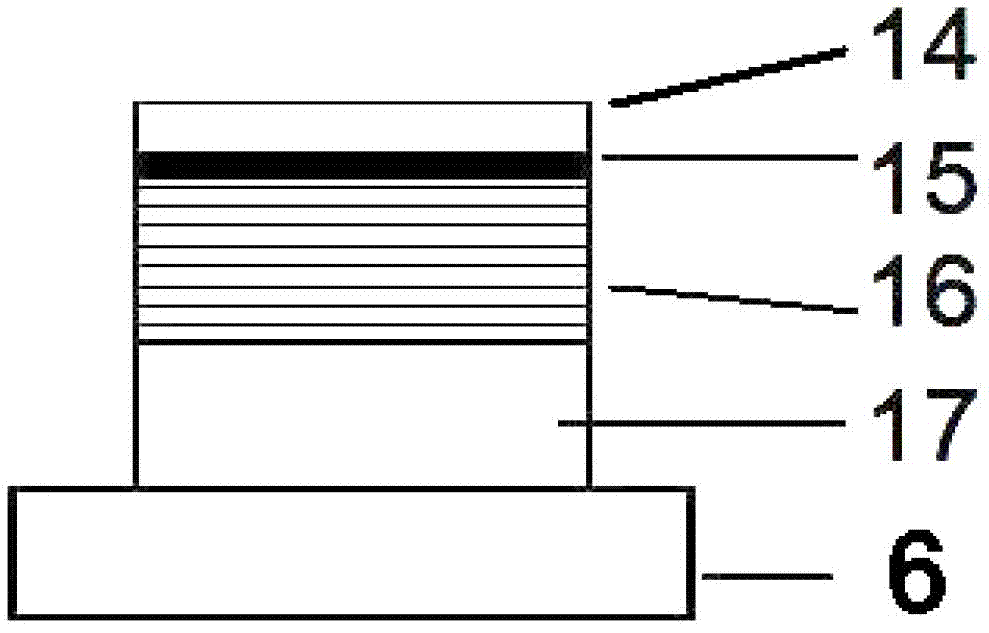

Embodiment 1

[0026] For the output pulsed light wavelength is the laser near 1 micron, the pump light source 1 is the semiconductor laser with the optical fiber output of 800-810nm wavelength; In the semiconductor gain chip 3, the semiconductor quantum well active layer 10 in the periodic quantum well layer is InGaAs, wherein the In content is 0.18-0.20, the quantum well barrier layer 11 in the periodic multi-quantum well layer is GaAs or AlGaAs, and the number of quantum wells is 6-16; the semiconductor Bragg mirror layer 12 is 26-28 For GaAs / AlAs. The semiconductor gain chip 3 uses a heat sink 4 to remove excess heat and control the chip temperature. The schematic diagram of the structure of the cooling device 4 is as Figure 4 As shown, the semiconductor gain chip is pasted on the heat sink 18 with heat-conducting glue, and the heat sink is copper or pure copper; the heat sink 18 is connected to the semiconductor refrigerator 19 with In to control the chip temperature; the semiconducto...

Embodiment 2

[0028] It is 630-670nm semiconductor laser that the pump light source in embodiment 1 is changed into wavelength, the periodic multi-quantum well layer is changed into GaAs / AlGaAs quantum well and potential barrier, and graphene saturable absorption mirror is changed into the absorption of carbon nanotube material The mirror can obtain the mode-locked pulse light output near 850nm.

Embodiment 3

[0030] It is the semiconductor laser of 808nm that the pumping light source among the embodiment 1 is changed into, the periodic multi-quantum well layer is changed into GaInNAs / GaAs quantum well and potential barrier, and the graphene saturable absorbing mirror is changed into the carbon nanotube material absorbing mirror, Then the mode-locked pulse light output near 1220nm can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com