Preparation of monodisperse styrene-acrylic composite emulsion nanoparticles

A technology of styrene-acrylic composite emulsion and nano particles, which is applied in the field of styrene-acrylic composite emulsion, can solve the problems of uneven distribution and uneven size, and achieve the effect of narrow particle size distribution, low cost and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 1.4g of styrene, 0.5g of sodium lauryl sulfate, and 60g of deionized water into a four-necked flask, and pre-emulsify with magnetic stirring at 75°C for 30min, and adjust the pH of the system at 8.0~9.0. Prepare a pre-emulsion. Add 0.01 g of ammonium persulfate to carry out seed emulsion polymerization, and keep warm for 30 minutes. Then add 0.12g of ammonium persulfate and 2g of sodium lauryl sulfate, and 12.6g of styrene, 16g of butyl methacrylate, and 1.5g of KH-570 mixed monomers, and add dropwise to the seed emulsion within 2 hours by controlling the rate of addition In, carry out polymerization, heat preservation reaction 5h. Finally, the temperature was lowered to 50°C and filtered to obtain a silicon-containing nano-scale polyacrylate composite emulsion.

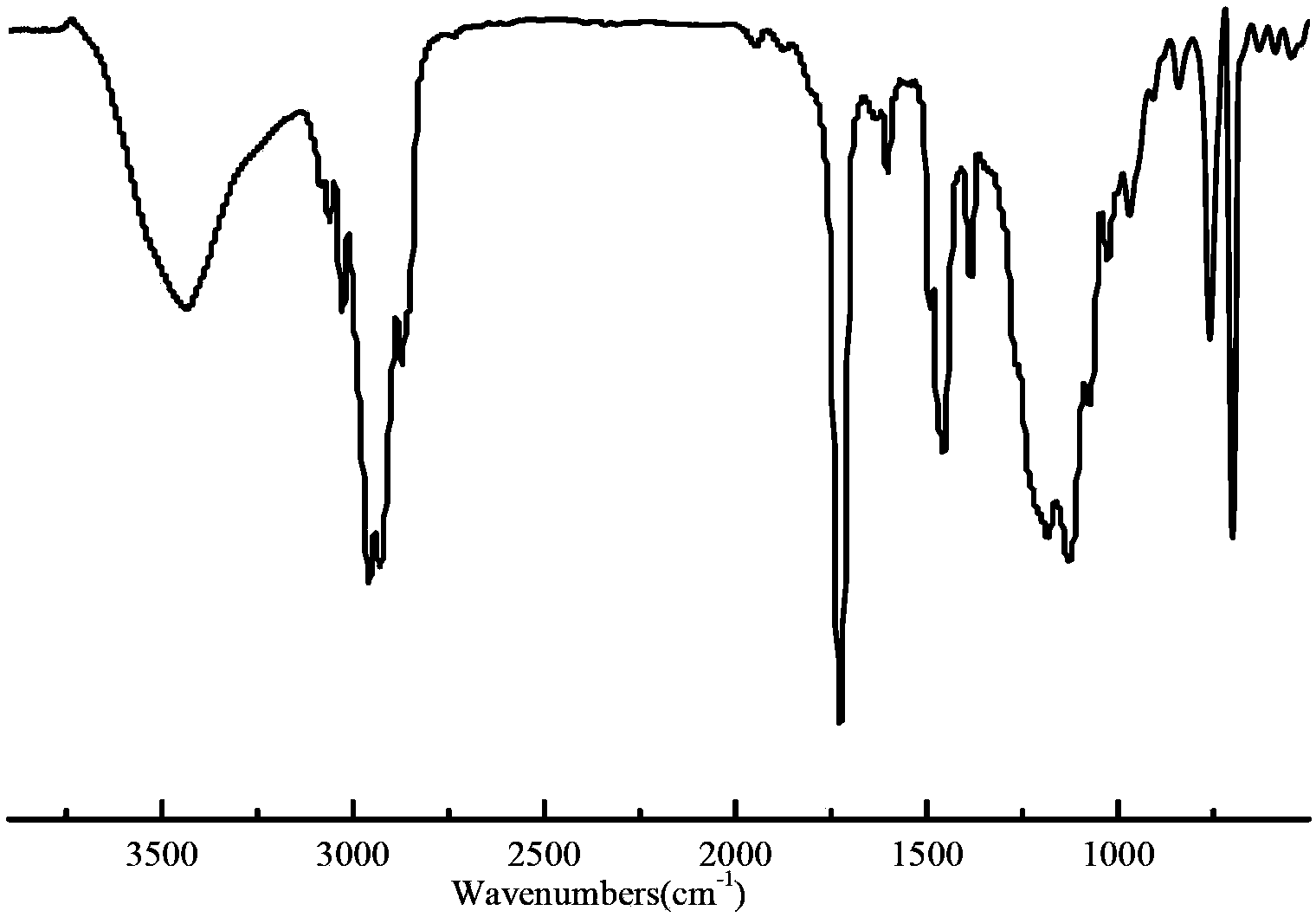

[0029] figure 1 It is the infrared spectrogram of the composite latex film of the present embodiment. figure 1 Medium for PBMA, 1725cm -1 The place is the infrared characteristic absorption peak cause...

Embodiment 2

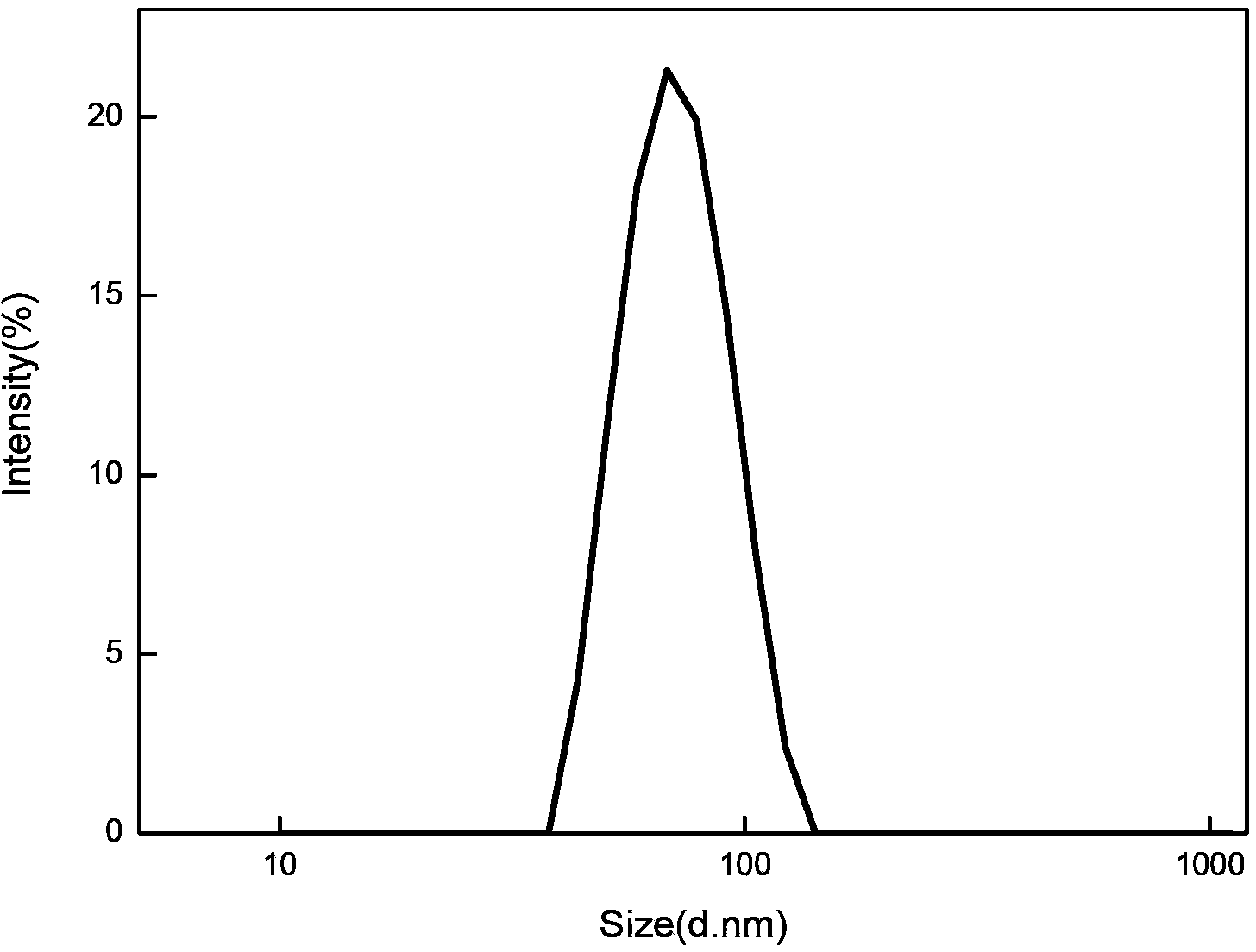

[0033] Add 1 g of styrene, 0.5 g of sodium dodecylbenzene sulfonate, and 60 g of deionized water into a four-neck flask, pre-emulsify with magnetic stirring at 75 °C for 35 min, and adjust the pH value with 25% sodium carbonate At 8.0~9.0, a pre-emulsion is prepared. Then add 0.01 g of ammonium persulfate to carry out seed emulsion polymerization, and keep warm for 30 minutes. Then add 0.09g ammonium persulfate and 1.5g sodium dodecylbenzenesulfonate, and 16g styrene, 15g butyl methacrylate, and 1.5g KH-571 mixed monomer, and control the rate of addition dropwise to In the seed emulsion, keep warm for 5 hours. Finally, the temperature was lowered to 40° C. and filtered to obtain a silicon-containing nano-scale polyacrylate composite emulsion. The latex particles are small spherical, evenly distributed and uniform in size, and the size of the particles is about 60-70nm.

Embodiment 3

[0035] Add 1.5g of styrene, 0.5g of allyloxy hydroxypropyl sodium sulfonate, and 50g of deionized water into a four-necked flask, and pre-emulsify with magnetic stirring at 80°C for 40min. Adjust the pH value at 8.0~9.0 to prepare the pre-emulsion. Then add 0.03 g of ammonium persulfate to carry out seed emulsion polymerization, and keep the temperature for 40 minutes. Then add 0.09g of ammonium persulfate and 1.5g of allyloxy hydroxypropyl sodium sulfonate, and 12.5g of styrene, 16g of butyl methacrylate, and 3g of KH-572 mixed monomer, and add them dropwise to the seeds within 3h. In the emulsion, keep warm for 4 hours. Finally, the temperature was lowered to 30°C and filtered to obtain a silicon-containing nano-scale polyacrylate composite emulsion. The latex particles are small spherical, evenly distributed and uniform in size, and the size of the particles is about 60-70nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com