Halogen-free environmentally-friendly cationic antistatic agent and preparation method thereof

A cationic, antistatic agent technology, applied in the field of halogen-free environment-friendly cationic antistatic agent and its preparation, can solve the problems of not cheap and easy to obtain synthetic raw materials, poor antistatic effect, affecting product quality, etc., and achieve good stability Long-lasting antistatic effect, convenient for continuous industrial production, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

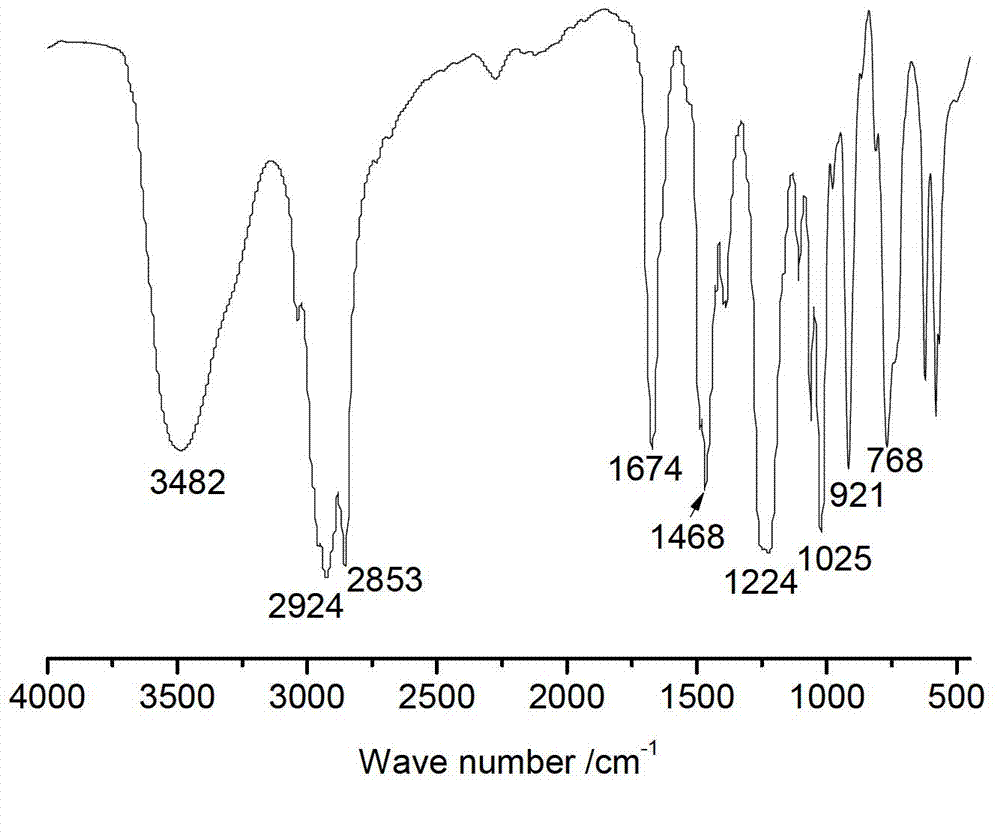

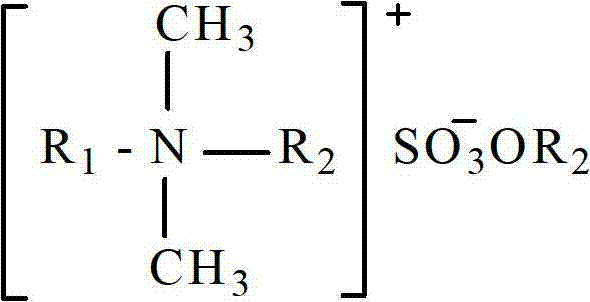

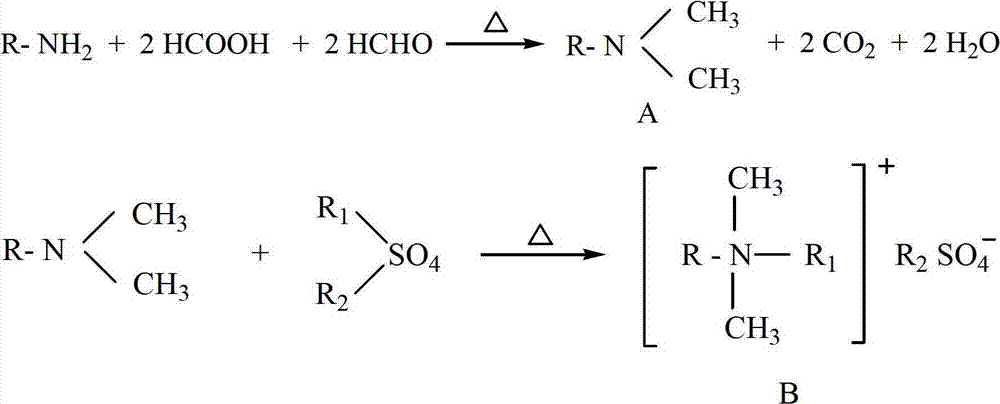

[0034] Add 100g of octadecyl primary amine and 30g of isopropanol into a four-necked flask previously purged with nitrogen, add 78g of formic acid while stirring, heat up to 80°C, add 80g of formaldehyde, and complete the addition in about 2 hours. After the addition was completed, react at a constant temperature of 100°C for 2 hours, add 40g of formaldehyde, finish the addition in 1 hour, and react at a constant temperature of 100°C for 18 hours. The reaction product was neutralized with 30 ml of 40% sodium hydroxide solution, washed with water until neutral, and the organic layer was separated, solvent removed, and vacuum-dried to obtain a tertiary amine with a yield of 91.8%. Add the tertiary amine into a four-neck bottle purged with nitrogen, add 35g of ethylene glycol, add 50g of diethyl sulfate dropwise under vigorous stirring, and finish the addition in 1 hour. Static agent product octadecyl ethyl dimethyl ammonium ethyl sulfate, the appearance is a yellowish viscous li...

Embodiment 2

[0036] Add 100g of dodecyl primary amine and 30g of n-hexane into a four-necked flask previously purged with nitrogen, add 78g of formic acid while stirring, heat up to 70°C, add 120g of formaldehyde, and complete the addition in about 2 hours. After the addition was completed, the reaction was carried out at a constant temperature of 70°C for 20 hours. The reaction product was neutralized with 30 ml of 40% sodium hydroxide solution, washed with water until neutral, and the organic layer was separated, solvent removed, and vacuum-dried to obtain a tertiary amine with a yield of 90.2%. Add the tertiary amine into a four-neck bottle purged with nitrogen, add 48g of dimethyl sulfate dropwise under vigorous stirring, and finish adding in 1 hour. After the addition, quickly raise the temperature to 50°C and react at a constant temperature for 5 hours to obtain the antistatic agent product dodecane Ethyl dimethyl ammonium ethyl sulfate, the appearance is light yellow viscous liquid,...

Embodiment 3

[0038] Add 100g of tetradecyl primary amine and 30g of n-butanol into a four-necked flask previously purged with nitrogen, add 78g of formic acid while stirring, heat up to 80°C, add 120g of formaldehyde, and complete the addition in about 2 hours. After the addition was completed, the reaction was carried out at a constant temperature of 80°C for 15 hours. The reaction product was neutralized with 30 ml of 40% sodium hydroxide solution, washed with water until neutral, and the organic layer was separated, solvent removed, and vacuum-dried to obtain a tertiary amine with a yield of 92.2%. Add the tertiary amine into a four-necked bottle purged with nitrogen, add 35g of n-butanol, add 50g of diethyl sulfate dropwise under vigorous stirring, and finish adding in 1 hour. The electrostatic agent product tetradecyl ethyl dimethyl ammonium ethyl sulfate, the appearance is a colorless viscous liquid, the pH of the solution is 7.1 (2g / 100ml), the free amine in the product is 0.8%, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com