Preparation method of non-dissolving antibacterial polyquaternium modified active carbon

A polyquaternary ammonium salt and activated carbon technology is applied in chemical instruments and methods, sterilization/microdynamic water/sewage treatment, adsorbed water/sewage treatment, etc. The raw materials are easily available and the effect of good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

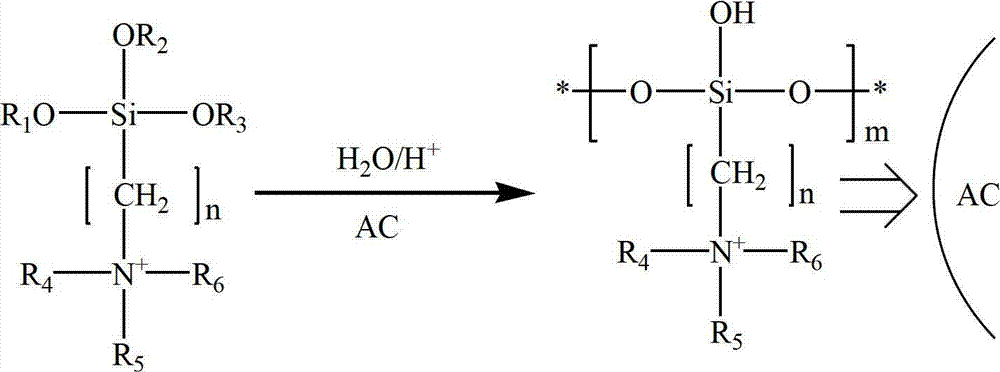

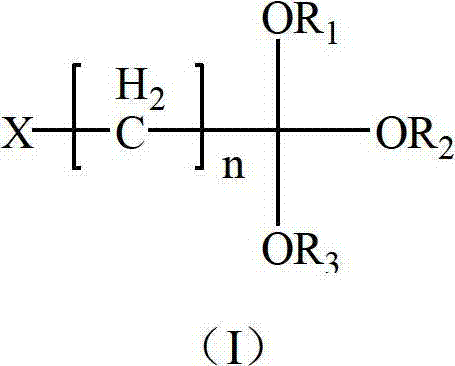

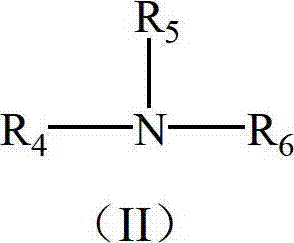

[0024] This example is the preparation of 3-(trimethoxysilyl) C-grade cetyl dimethyl ammonium chloride, and the reaction formula is as follows:

[0025]

[0026] Weigh 12.03g (0.06mol) of 3-chloropropyl-trimethoxysilane, 8.15g (0.03mol) of hexadecyldimethyl tertiary amine, add 21.93g (0.3mol) of N,N-dimethylformaldehyde Amide (DMF), filled with nitrogen protection, stirred and reacted at 110°C for 28-30h, and the reactants were removed by rotary evaporation to remove the solvent and excess reactants to obtain 3-(trimethoxysilyl) C-decadeca with a content of 96%. Hexaalkyldimethylammonium chloride, the crude product was purified by acetone to obtain a pure product, the elemental analysis test value: C / %61.45 (61.56), N / %2.98 (2.99)H / %11.63 (11.62) (in brackets is theoretical value); m / z 432.30; IR(KBr cm -1 ): 3430.86, 2921.05, 2851.13, 1195.30, 1076.42.

[0027] Methanol, ethanol, propanol can be used instead of DMF, or mixed solution of methanol and DMF, the reaction res...

Embodiment 2

[0029] This example is the on-site polymerization reaction of 3-(trimethoxysilyl) C-grade cetyl dimethyl ammonium chloride on activated carbon.

[0030] Weigh 0.2g of quaternary ammonium salt into a 250ml conical flask with stopper, add 38ml of deionized water, after ultrasonic dissolution, add 4g of activated carbon, shake at room temperature for 30min, add 2ml of 4mol / L hydrochloric acid solution, adjust the hydrochloric acid solution The concentration is 0.2mol / L, placed in a constant temperature shaking water tank at 50°C for 6 hours, after the reaction is completed, wash with deionized water until the solution is clear, and dry in a blast drying oven at 80°C for 2 hours to obtain modified activated carbon. Loading 1.07×10 per gram of activated carbon -4 mol quaternary ammonium salt.

Embodiment 3

[0032] This example is the on-site polymerization reaction of 3-(trimethoxysilyl) C-grade cetyl dimethyl ammonium chloride on activated carbon.

[0033] In the experiment, 0.1g of quaternary ammonium salt was weighed and added to a 250ml conical flask with a stopper, 47.5ml of deionized water was added, after ultrasonic dissolution, 5g of activated carbon was added, and after shaking at room temperature for 30min, 2.5ml of 4mol / L hydrochloric acid solution was added. Adjust the concentration of the solution to 0.2 mol / L and place it in a 50°C constant temperature shaking water tank for 6 hours of reaction. After the reaction is complete, wash it with deionized water until the solution is clear, and dry it in an 80°C blast drying oven for 2 hours to prepare modified activated carbon. The loading per gram of activated carbon is 4.29×10 -5 mol quaternary ammonium salt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com