Preparation method of spherical gadolinium-doped titanium dioxide photocatalyst

A spherical photocatalyst, titanium dioxide technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve complex processes, waste of raw materials, difficult control of mixing speed, etc. problems, to achieve the effect of stable product properties, high application value, and high dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A sol-gel method is used to prepare gadolinium-doped nano-titanium dioxide photocatalysts, and the specific steps are as follows:

[0037] (1) Prepare a mixed solution of 10ml tetrabutyl titanate, 60ml absolute ethanol and 1ml nitric acid and stir.

[0038] (2) Add 0.0258 g of gadolinium nitrate (0.2% by mole to titanium dioxide) into the above solution, and stir to dissolve it completely.

[0039] (3) Add 2 ml of deionized water to the above solution, and vigorously stir (800 rpm) while the tetrabutyl titanate is rapidly hydrolyzed to make it evenly mixed.

[0040] (4) The obtained mixed solution was dried in a constant temperature drying oven at 60° C. for 24 hours.

[0041] (5) Grinding the obtained product and calcining it in a muffle furnace at 450° C. for 3 hours to obtain gadolinium-doped titanium dioxide nanoparticles.

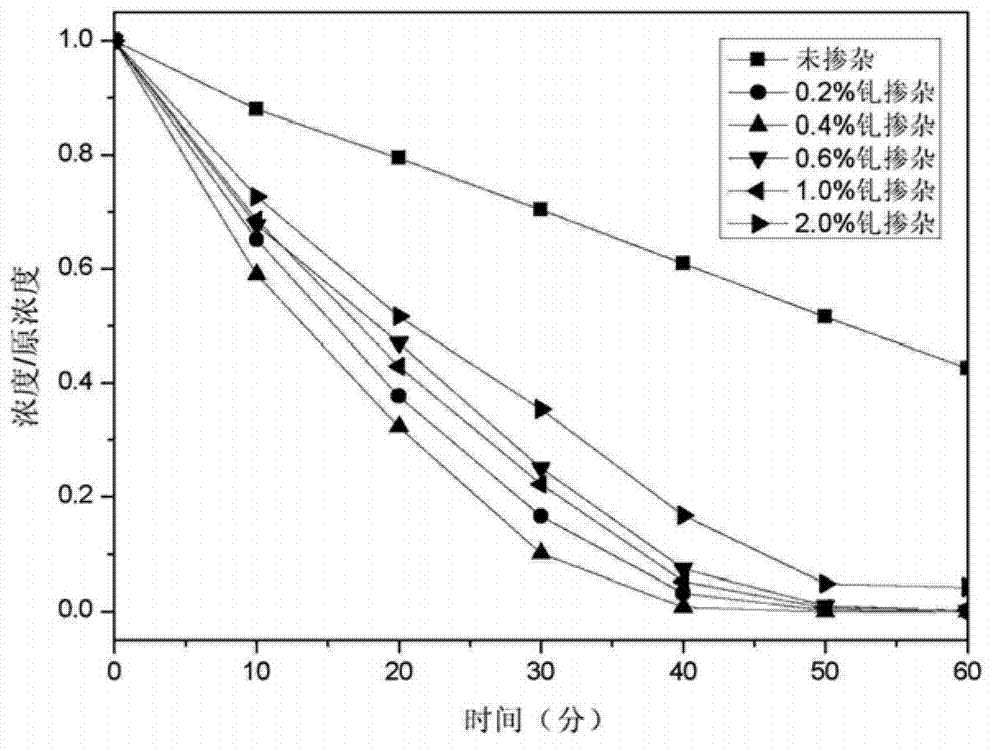

[0042] The prepared anatase-type doped titanium dioxide has a small crystal grain size of about 10.89 nanometers, and its photocatalytic acti...

Embodiment 2

[0044] A sol-gel method is used to prepare gadolinium-doped nano-titanium dioxide photocatalysts, and the specific steps are as follows:

[0045] (1) Prepare a mixed solution of 10ml tetrabutyl titanate, 60ml absolute ethanol and 1ml nitric acid and stir.

[0046] (2) Add 0.0529 g of gadolinium nitrate (0.4% by mole to titanium dioxide) into the above solution, and stir to dissolve it completely.

[0047] (3) Add 2 ml of deionized water to the above solution, and stir vigorously (rotating at 800 rpm) to make it evenly mixed while the tetrabutyl titanate is rapidly hydrolyzed.

[0048] (4) The obtained mixed solution was dried in a constant temperature drying oven at 80° C. for 12 hours.

[0049] (5) Grinding the obtained product and calcining it in a muffle furnace at 450° C. for 3 hours to obtain gadolinium-doped titanium dioxide nanoparticles.

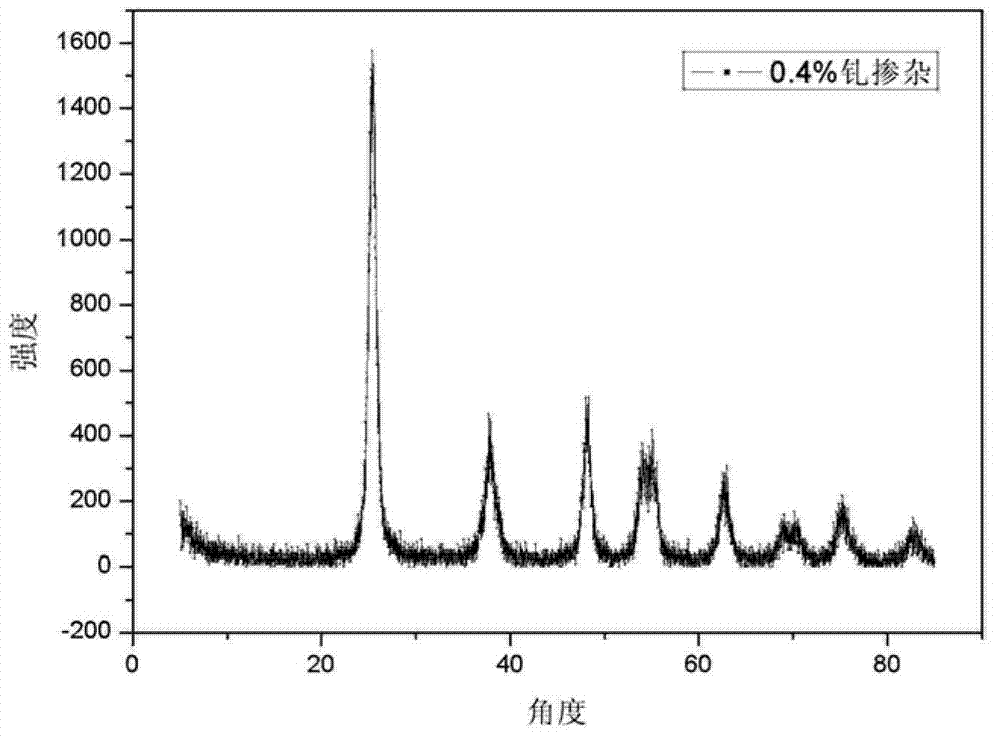

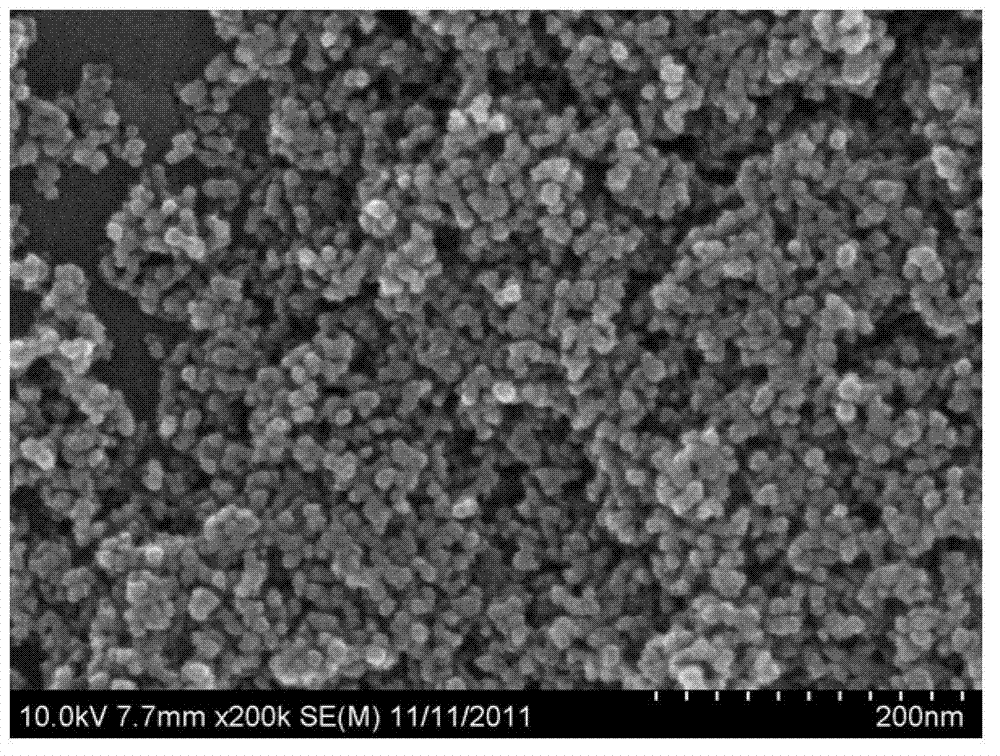

[0050] The obtained product was characterized by XRD and SEM for its structure and crystal form, figure 1 , 2 XRD and SEM patte...

Embodiment 3

[0052] The rare earth gadolinium-doped nano-titanium dioxide photocatalyst was prepared by a sol-gel method, and the specific steps were as follows:

[0053] (1) Prepare a mixed solution of 10ml tetrabutyl titanate, 60ml absolute ethanol and 1ml nitric acid and stir.

[0054] (2) Add 0.0792 g of gadolinium nitrate (0.6% by mole to titanium dioxide) into the above solution, and stir to dissolve it completely.

[0055] (3) Add 3 ml of deionized water to the above solution, and vigorously stir (rotating at 800 rpm) while the tetrabutyl titanate is rapidly hydrolyzed to make it evenly mixed.

[0056] (4) The obtained mixed solution was dried in a constant temperature drying oven at 80° C. for 12 hours.

[0057] (5) Grinding the obtained product and calcining it in a muffle furnace at 450° C. for 3 hours to obtain gadolinium-doped titanium dioxide nanoparticles.

[0058] The product of gadolinium-doped titania has good crystallinity, and its average particle size is about 6.59 nm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com