Three-dimensional large-aperture nanoscale fibrous scaffold and method for preparing same

A fibrous scaffold, large pore size technology, applied in scaffolds, medical science, blood vessels, etc., can solve the problems of affecting cell adhesion and growth, insufficient cell affinity, low adhesion, etc., and achieve good cell adhesion and good biological phase. Capability and tissue regeneration ability, the effect of less infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Preparation of fiber mat

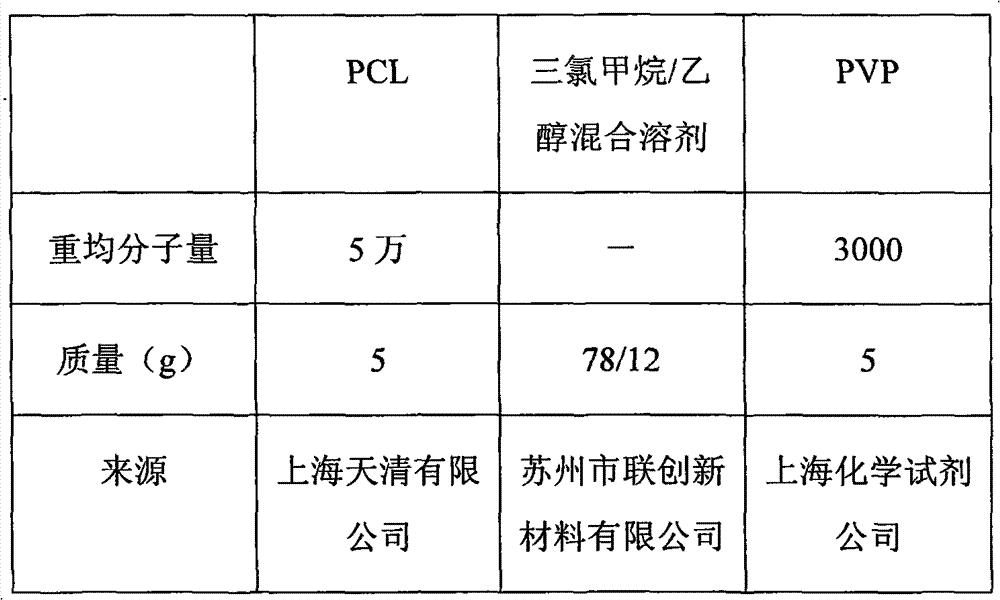

[0026]

[0027] Electrospinning parameter control

[0028]

[0029] The purified PCL and PVP polymers with a weight fraction of 10% are dissolved in an organic solvent to obtain a transparent and uniform organic solution containing 5% by weight of the purified PCL polymer and 5% by weight of PVP. That is, the electrospinning stock solution.

[0030] Electrospinning was carried out with the prepared electrospinning stock solution. The spinning parameters were controlled at a voltage of 15kv, a nozzle aperture of 0.4mm, a solution flow rate of 1ml / h, an ambient temperature of 20°C, and a distance of 15cm between the receiving plate and the nozzle.

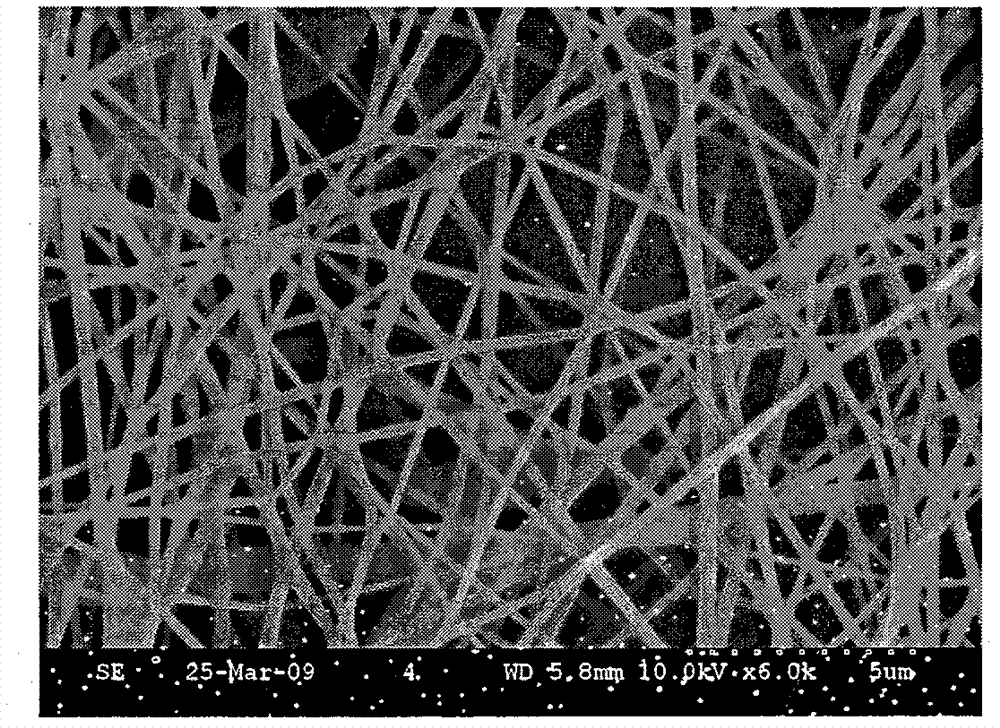

[0031] (2) Preparation of macroporous nanofiber scaffolds

[0032] Within 48 hours after spinning, the fiber mat was immersed in the organic solvent ethanol, pre-frozen at -200°C for 8 hours, and then frozen at -4°C, using CO 2 The atmosphere was dried for 24 hours, and a three-dimensio...

Embodiment 2

[0034] (1) Preparation of fiber mat

[0035]

[0036] Electrospinning parameter control

[0037]

[0038] The purified PCL and PVP polymers with a weight fraction of 40% were dissolved in an organic solvent to obtain a transparent and uniform organic solution containing 4% by weight of the purified PCL polymer and 36% by weight of PVP. That is, the electrospinning stock solution.

[0039] Electrospinning was carried out with the prepared electrospinning stock solution. The spinning parameters were controlled at a voltage of 20kv, a nozzle aperture of 0.7mm, a solution flow rate of 2ml / h, an ambient temperature of 25°C, and a distance between the receiving plate and the nozzle of 10cm.

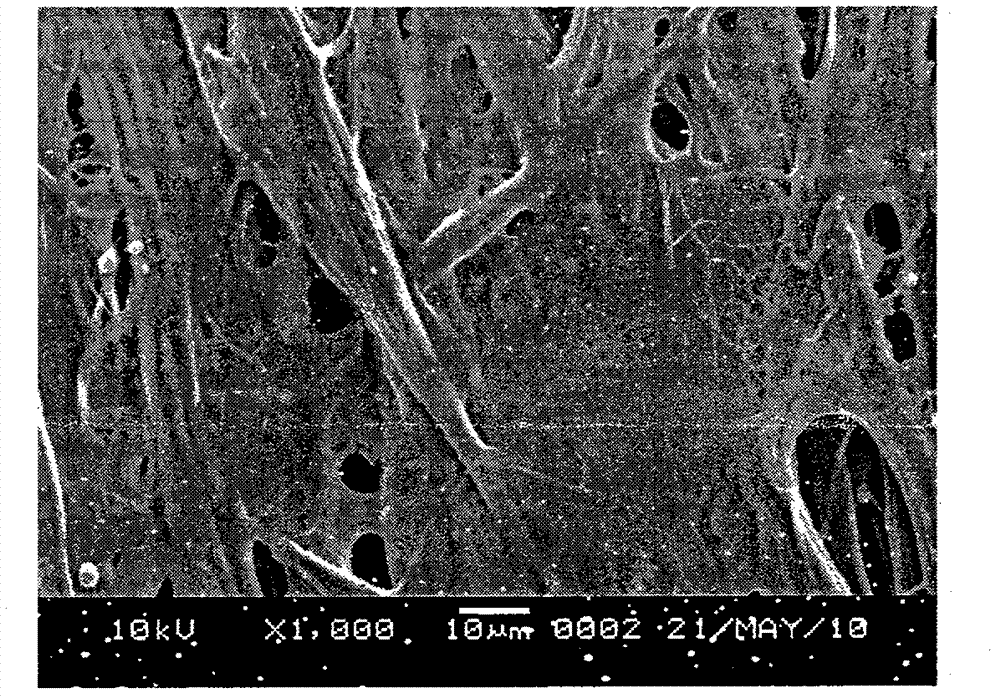

[0040] (2) Preparation of macroporous nanofiber scaffolds

[0041] Within 48 hours after spinning, the fiber mat was immersed in the organic solvent acetone, pre-frozen at -4°C for 8 hours, and then frozen at -40°C, using CO 2 The atmosphere was dried for 12 hours, and a three-dimensi...

Embodiment 3

[0043] (1) Preparation of fiber mat

[0044]

[0045] Electrospinning parameter control

[0046]

[0047]The purified PLGA and PEO polymers with a weight fraction of 30% were dissolved in an organic solvent to obtain a transparent and uniform organic solution containing 9% by weight of the purified PLGA polymer and 21% by weight of PVP. That is, the electrospinning stock solution. Electrospinning was carried out with the prepared electrospinning stock solution. The spinning parameters were controlled at a voltage of 30kv, a nozzle aperture of 0.1mm, a solution flow rate of 0.2ml / h, an ambient temperature of 40°C, and a distance of 2cm between the receiving plate and the nozzle.

[0048] (2) Preparation of macroporous nanofiber scaffolds

[0049] Within 48 hours after spinning, immerse the fiber mat in a mixed solvent of organic solvent methanol and water, pre-freeze at minus 100°C for 1 hour, then freeze at 4°C, and apply CO 2 The atmosphere was dried for 48 hours, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com