Preparation method of magnetic charcoal for efficiently removing tetracycline

A biochar, tetracycline technology, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve problems such as adverse health effects, enhancement, etc., to promote sustainable development, important environmental protection, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1. Salvage and harvest the natural algal blooms, dry them in the sun, crush them, and pass them through a 100-mesh sieve;

[0018] 2. Preparation of magnetic biochar: Add 3 mmol of ferrous ammonium sulfate and 3 g of cyanobacteria with a dry weight of 3 g to each 100 ml of aqueous solution, mix evenly, and then sonicate for 1 h, then transfer to a 100 ml high-pressure reactor and react at 170 ° C for 12 h, then pass Centrifuge, wash, and dry to obtain magnetic biochar;

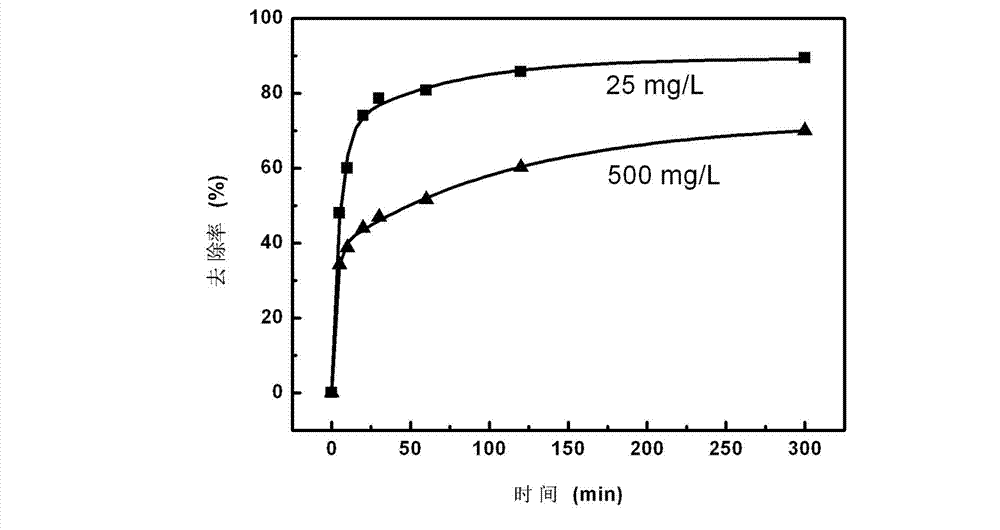

[0019] 3. The process of removing tetracycline: Add magnetic biochar to the tetracycline-containing wastewater according to the standard of adding 0.4 g magnetic biochar to the tetracycline-containing wastewater by adding the above-mentioned magnetic biochar with a concentration of 50 ppm to 50 ppm of the magnetic biochar, and at room temperature with The frequency of 140 rpm was oscillated for 5 hours for adsorption, and the removal efficiency was 87.1%.

Embodiment 2

[0021] 1. Salvage and harvest the natural algal blooms, dry them in the sun, crush them, and pass them through a 100-mesh sieve;

[0022] 2. Preparation of magnetic biochar: Add 3 mmol of ferrous ammonium sulfate and 3 g of cyanobacteria with dry weight to 100 ml of aqueous solution, mix evenly, then sonicate for 1 h, then transfer to 100 ml of high-pressure reaction axe, react at 190 ° C for 12 h, and then centrifuge , washing and drying to obtain magnetic biochar;

[0023] 3. The process of removing tetracycline: Add magnetic biochar to the tetracycline-containing wastewater according to the standard of adding 0.4 g magnetic biochar to the tetracycline-containing wastewater by adding the above-mentioned magnetic biochar with a concentration of 50 ppm to 50 ppm of the magnetic biochar, and at room temperature with Oscillating at a frequency of 140 rpm for 5 hours, the removal efficiency was 83.8%.

Embodiment 3

[0025] 1. Salvage and harvest the natural algal blooms, dry them in the sun, crush them, and pass them through a 100-mesh sieve;

[0026] 2. Preparation of magnetic biochar: Add 3 mmol of ferrous ammonium sulfate and 3 g of cyanobacteria with a dry weight to each 100 ml of aqueous solution, mix evenly, and sonicate for 1 h, then transfer to a high-pressure reaction ax and react at 210 ° C for 12 h, then centrifuge, Washing and drying to obtain magnetic biochar;

[0027] 3. The process of removing tetracycline: Add magnetic biochar to the tetracycline-containing wastewater according to the standard of adding 0.4 g magnetic biochar to the tetracycline-containing wastewater by adding the above-mentioned magnetic biochar with a concentration of 50 ppm to 50 ppm of the magnetic biochar, and at room temperature with Oscillating at a frequency of 140 rpm for 5 hours, the removal efficiency was 51.6%.

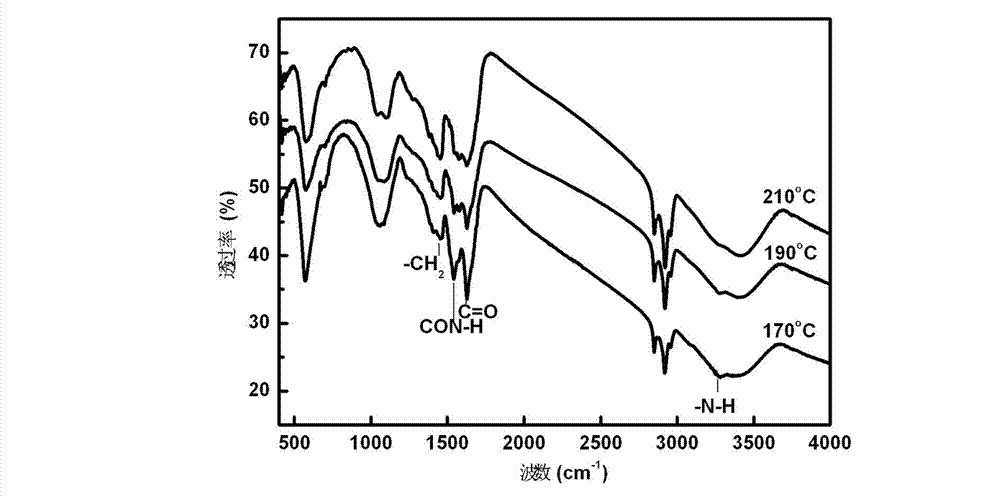

[0028] figure 1 Infrared spectra of magnetic biochar at different hydrothermal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com