Aqueous solution full-cycle urea energy-saving production process

An aqueous solution full circulation and production process technology, applied in the product, chemical industry, preparation of urea derivatives, etc., can solve the problems of poor heat recovery and utilization, poor operation controllability, high material consumption, and reduce load and material consumption. , The effect of maintaining system water balance and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

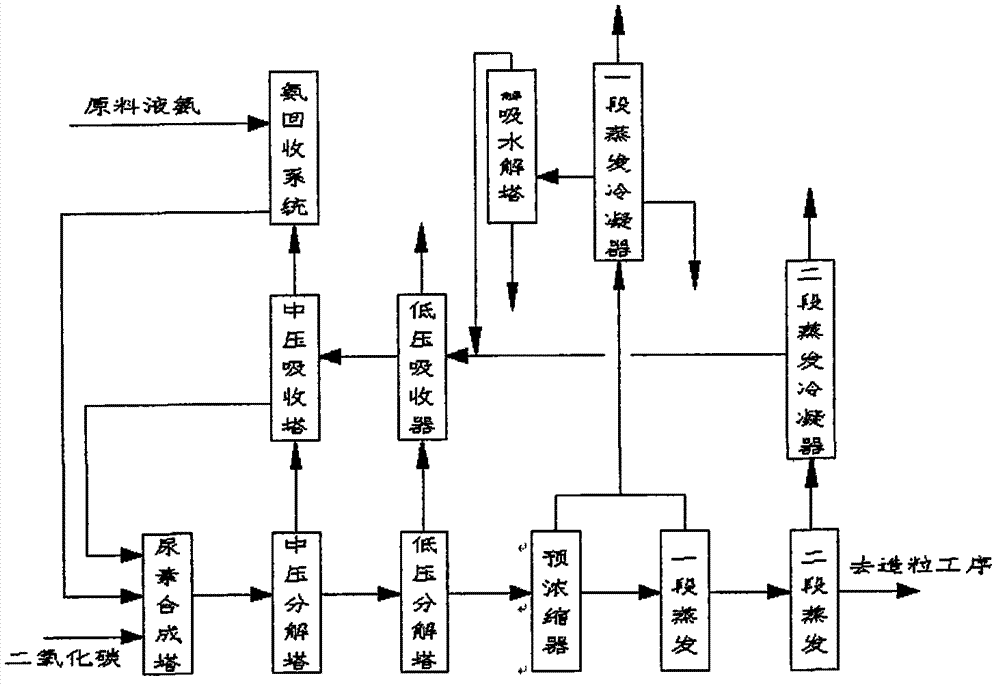

[0023] Such as figure 1 The energy-saving production process of full cycle urea in aqueous solution shown, the main equipment includes liquid phase countercurrent heat exchange urea synthesis tower, urea medium pressure absorption tower, horizontal submerged tail gas absorber, evaporative condenser and desorption hydrolysis tower, the process is as follows :

[0024] 1) High pressure synthesis process:

[0025] The raw material liquid ammonia from the ammonia storehouse is pressurized to 20-23MPa by the liquid ammonia pump and then sent to the liquid ammonia preheater, which is heated to 70°C and divided into two paths, one of which is about 80% of the total amount of NH 3 , 103°C methylammonium solution and from CO 2 Compressor 20~23MPa CO 2 Enter the distributor at the top of the synthesis tower together; the other way is about 20% NH 3 It enters through the bottom of the urea synthesis tower, completes the isothermal and high-pressure synthesis reaction in the tower, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com