Quick-drying type environmental protection water epoxy floor paint and preparation method thereof

An epoxy floor paint, quick-drying technology, used in epoxy resin coatings, coatings, etc., can solve problems such as poor flexibility, brittleness, poor impact resistance, and hidden dangers in application, to reduce VOC release and improve Coating performance, the effect of enhancing environmental advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

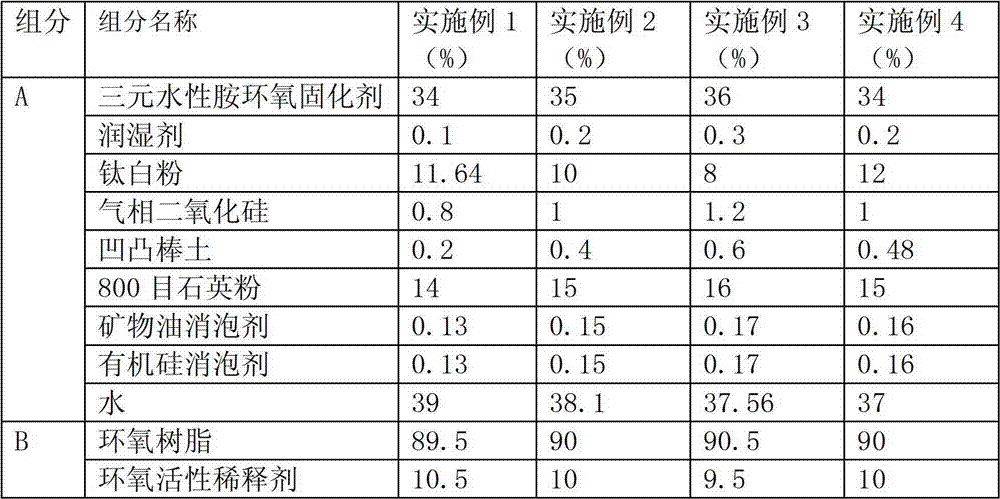

Embodiment 1

[0063] The components of Example 1 specified in Table 1 were prepared according to the following steps, but the ternary water-based amine epoxy curing agent was modified aliphatic amine, modified alicyclic amine and water-based polyamide in a weight ratio of 3.2:3.0:2.5 Mixed mixture, the wetting agent is polyoxyethylene tetrafluorocarbon ether, and the epoxy reactive diluent is AGE.

[0064] Prepare component A:

[0065] a. Add 15% water of the total weight of the formula and 20% ternary water-based amine epoxy curing agent of the total weight of the formula into the dispersion tank in sequence, and then add wetting agent and mineral oil defoamer at a shear rate of 8 The medium and low speed of m / s is evenly dispersed;

[0066] b. Then add fumed silica, attapulgite, titanium dioxide, and 800-mesh quartz powder in sequence, wash the cylinder wall with an appropriate amount of water, and increase the shear speed to a high speed of 24 m / s to disperse evenly;

[0067] c. Finall...

Embodiment 2

[0071] The components of Example 2 specified in Table 1 were prepared according to the following steps, but the ternary water-based amine epoxy curing agent was modified aliphatic amine, modified alicyclic amine and water-based polyamide in a weight ratio of 4.2:4.0:3.0 Mixed mixture, the wetting agent is polyoxyethylene alkyl ether, and the epoxy reactive diluent is BGE.

[0072] Prepare component A:

[0073] a. Add water of 15% of the total weight of the formula, ternary water-based amine epoxy curing agent of 20% of the total weight of the formula, and then add wetting agent and mineral oil defoamer in the dispersion tank at a shear rate of 9 The medium and low speed of m / s is evenly dispersed;

[0074] b. Then add fumed silica, attapulgite, titanium dioxide, and 800-mesh quartz powder in sequence, rinse the cylinder wall with an appropriate amount of water, and increase the shear speed to a high speed of 25 m / s to disperse evenly;

[0075] c. Finally, adjust the shearing...

Embodiment 3

[0079] The components of Example 3 specified in Table 1 were prepared according to the following steps, but the ternary water-based amine epoxy curing agent was modified aliphatic amine, modified alicyclic amine and water-based polyamide in a weight ratio of 4:3.0:3.0 Mixed mixture, the wetting agent is sodium alkylbenzene sulfonate, and the epoxy reactive diluent is BGE.

[0080] Prepare component A:

[0081] a. Add 15% water of the total weight of the formula and 20% ternary water-based amine epoxy curing agent of the total weight of the formula into the dispersion tank in sequence, and then add wetting agent and mineral oil defoamer at a shear rate of 10 The medium and low speed of m / s is evenly dispersed;

[0082] b. Then add fumed silica, attapulgite, titanium dioxide, and 800-mesh quartz powder in sequence, wash the cylinder wall with an appropriate amount of water, and increase the shear speed to a high speed of 26 m / s to disperse evenly;

[0083] c. Finally, adjust t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com