Cell catalyzed by titanium dioxide, preparation method of cell and application

A battery and photocatalytic technology, applied in chemical instruments and methods, battery electrodes, circuits, etc., can solve the problems of long microbial reaction startup time, low electron transfer efficiency, harsh operating conditions, etc., to achieve easy control, extended response, and operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1 Preparation of nanometer TiO2 film and its photocatalytic treatment of organic wastewater

[0050] The preparation method reference of this laboratory (Dong Mei, Feng Shujing etc., chemical engineer, 2006, (11) 46-47), preparation method is as follows:

[0051] Dissolve 1g of ethyl cellulose in 7g of terpineol, then add industrial commodity P25 nanometer TiO 2 Powder 2g, and add a small amount of ethanol, grind the mixture in an agate mortar for half an hour until uniform, to obtain nano-TiO2 film paste.

[0052] nano-TiO by screen printing 2 The paste is printed onto the conductive glass. The printed TiO 2 The film was dried at room temperature for about 30 minutes, then placed in a muffle furnace for sintering at 520°C for 2 hours, the heating rate was 10°C / min, and it was taken out when the temperature dropped to room temperature.

[0053] attached figure 1 The nano-TiO prepared by the present invention and the Advanced Materials Laboratory of Fudan Un...

Embodiment 2

[0058] Embodiment 2: the preparation of nano-TiO2 photocatalytic waste water organic matter battery

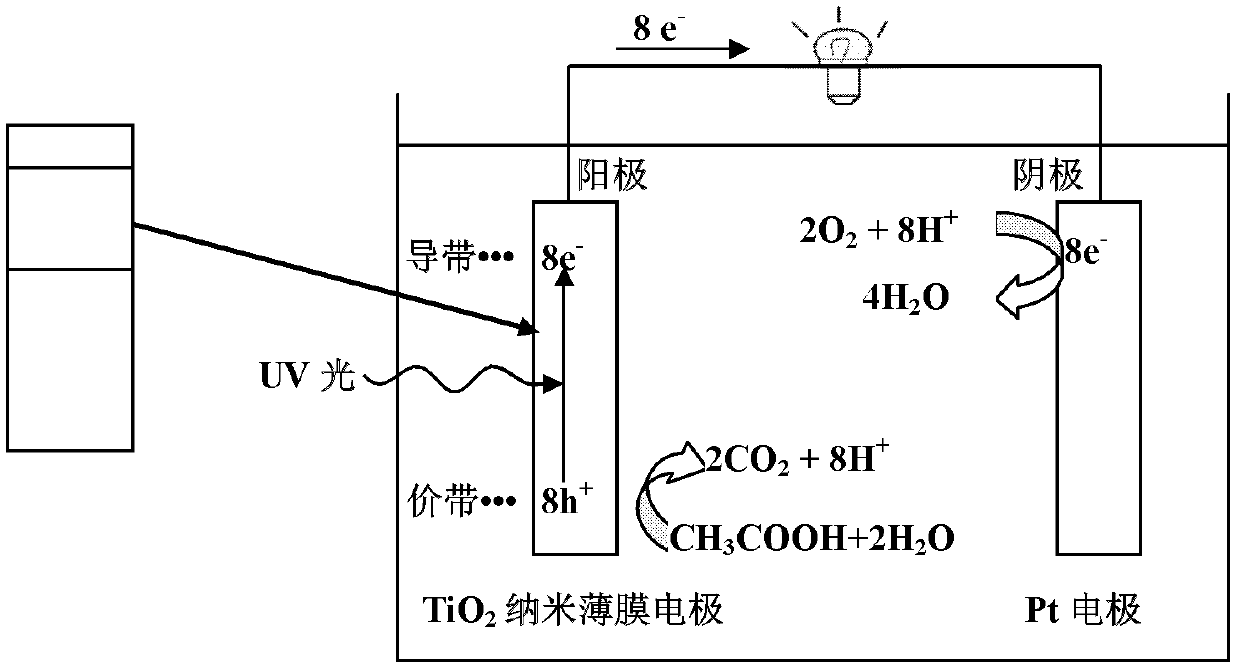

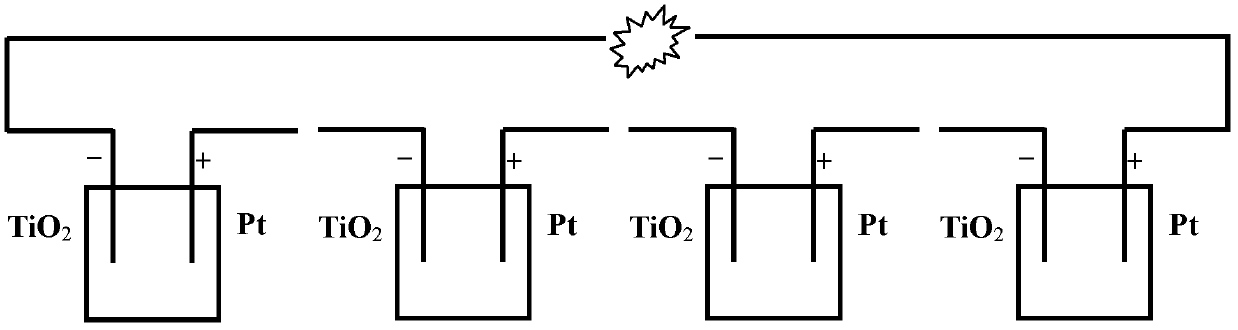

[0059] as attached figure 2 As shown, the nano-TiO2 film printed on the conductive glass is used as the anode, the platinum black electrode is used as the cathode, the wastewater organic matter (such as acetic acid) containing the electrolyte is placed in the reaction tank, and the light source is turned on to irradiate the nano-TiO2 film, which constitutes a photocatalytic Wastewater Organics Battery.

[0060] When ultraviolet light irradiates the nano-TiO2 catalyst on the surface of the thin film electrode (anode), the electrons in the valence band of the nano-TiO2 are excited, jump to the conduction band, and generate corresponding holes in the valence band. The generated holes and the hydroxyl radicals (OH) indirectly transformed have a strong oxidation effect, and can quickly oxidize the acetic acid molecules adsorbed on the surface of nano-TiO2 to generate CO2 and H +...

Embodiment 3

[0063] Example 3 Nano-TiO2 Performance test of photocatalyzed waste water organic matter battery

[0064] The invention adopts a single-cell battery, and uses an electrochemical workstation to characterize the performance of the battery.

[0065] Using simulated wastewater 0.1mol / L acetic acid (containing 0.1mol / L Na2SO4 electrolyte) as organic substrate, nano-TiO2 photocatalytic anode and platinum black cathode constitute photocatalytic wastewater organic battery, and the battery polarization curve measured by electrochemical workstation and power density curves (see attached Figure 4 ). The polarization curve of a battery shows the relationship between voltage and current during discharge. It can be seen from the polarization curve that the open circuit voltage (V oc ) reaches 1.45V, the short-circuit current (J SC ) is 4.358A / m 2 . It can be seen from the power density curve that the maximum output power density of the battery (P max )4.66W / m 2 .

[0066] The fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com