Micro-speaker oscillation plate edge material, micro-speaker oscillation plate, micro-speaker, and electronic apparatus

A technology of micro-speaker and vibrating membrane, which is applied in the direction of fixing/tightening of flat vibrating membrane, transducer diaphragm and vibrating membrane, etc. It can solve the problems of high heat resistance, insufficient resistance to multi-bending, damage, cracking, etc. , to achieve the effect of excellent internal friction, excellent vibration resistance and excellent characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The diaphragm edge material for a microspeaker of the present invention will be described.

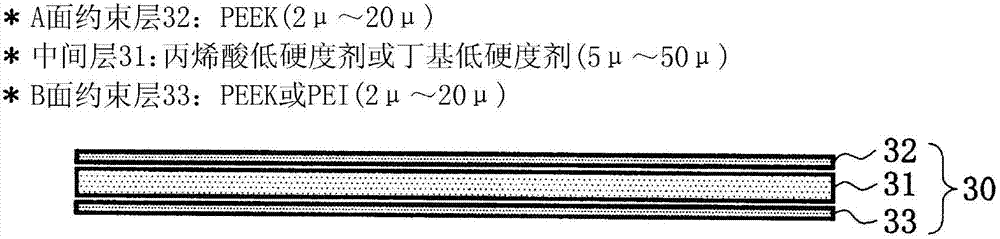

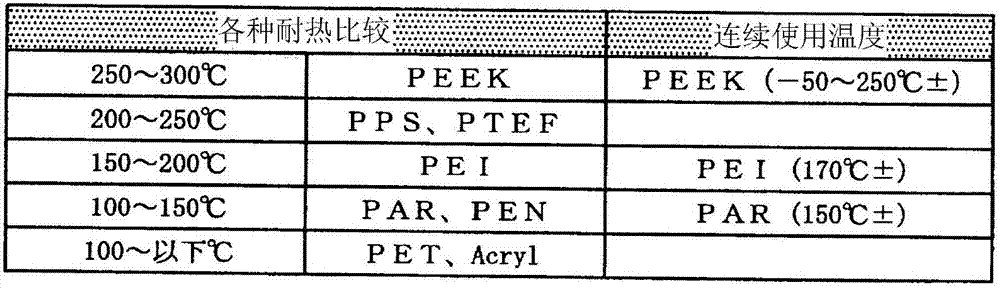

[0052] Such as figure 1 As shown, the diaphragm edge material 30 for a microspeaker of the present invention has a constrained layer (2 μm to 20 μm thick) 32, 33 made of PEEK from an intermediate layer (5 μm thick) made of acrylic low hardness agent or butyl low hardness agent. ~50μm) 31 clamping structure on both sides.

[0053] Figure 9A It is a graph showing the relationship between the thickness of the constraining layers 32 and 33 and the lowest frequency of the microspeaker. The optimum ranges for the thicknesses of the constraining layers 32 and 33 will be described below.

[0054] The horizontal axis of the graph is the lowest value of the output frequency of the microspeaker using the above-mentioned microspeaker diaphragm edge material 30 (hereinafter referred to as the lowest frequency (Hz)), and the vertical axis is the single PEEK used as the constraining layer...

Embodiment 2

[0085] Hereinafter, examples of a microspeaker diaphragm using the microspeaker diaphragm edge material having the above-mentioned excellent characteristics and a microspeaker incorporating the microspeaker diaphragm will be described with reference to the drawings.

[0086] Figure 3A and Figure 3B It is a figure for demonstrating an example of the diaphragm using the diaphragm edge material for microspeakers of this invention.

[0087] exist Figure 3A Among them, the reference numeral 20 is a high elastic material (paper, engineering plastic film or light metal sheet such as aluminum, magnesium), and the reference numeral 30 is a micro Loudspeaker diaphragm edge material.

[0088] The microspeaker diaphragm edge material 30 in this embodiment has a ring shape, and is integrally molded after being aligned so that its outer peripheral portion overlaps with the inner peripheral portion of the high elastic material 20 .

[0089] The high elastic material 20 and the diaphra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com