Essence particle additive as well as preparation method and application thereof

A technology of additives and particles, which is applied in applications, tobacco, and e-liquid filter elements, etc., can solve problems such as adverse effects on cigarette quality and uneven flavor diffusion, and achieve the effects of easy large-scale production, reduced flavor consumption, and a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

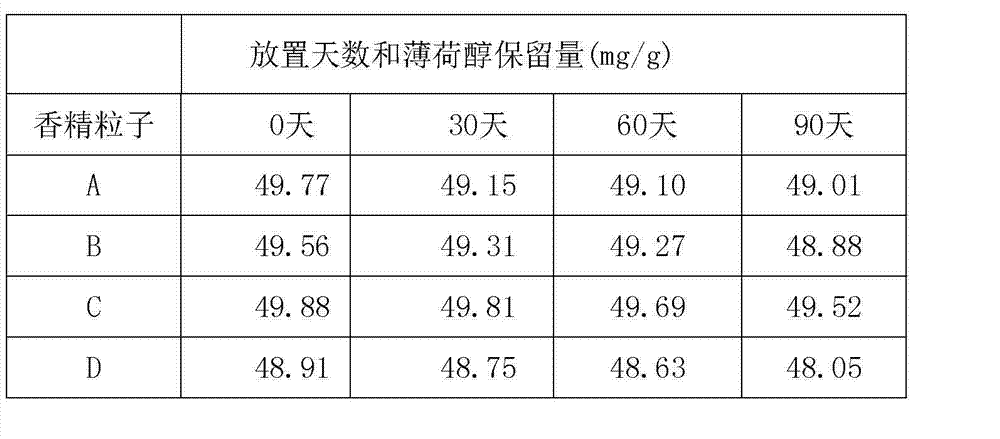

[0018] Put 100g of dried microcrystalline cellulose carrier with a particle size of 0.2mm in a fluidized bed granulation dryer, evenly spray 1L of 5.0g / L menthol solution, and evenly spray 1% carboxyl Methyl cellulose solution 20mL, after drying, microcrystalline cellulose essence particle A is obtained. Gas chromatography was used to measure the retention of menthol in essence particles at different times. The results are shown in Table 1.

Embodiment 2

[0020] Put 100g of dried tea powder with a particle size of 0.3mm in a fluidized bed granulation dryer, evenly spray 1L of 5.0g / L menthol solution, and evenly spray 1% pullulan under the condition of hot air at 40°C Solution 20mL, after drying, tea powder essence particle B is obtained. Gas chromatography was used to measure the retention of menthol in essence particles at different times. The results are shown in Table 1.

Embodiment 3

[0022] Evenly mix 5g of menthol and 100g of calcium carbonate particles with a particle size of 0.5mm, heat to 50°C to dissolve the menthol, stir vigorously to mix the calcium carbonate and menthol evenly, and slowly cool down to recrystallize the menthol on the surface of the calcium carbonate particles. Transfer the particles to a fluidized bed granulation dryer, and evenly spray 30mL of 0.5% sodium alginate solution under the condition of hot air at 40°C, and after drying, calcium carbonate essence particles C are obtained. Gas chromatography was used to measure the retention of menthol in essence particles at different times. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com