Zirconia, hydroxyapatite and magnesium phosphate laminar composite

A layered composite material, the technology of hydroxyapatite, applied in medical science, prosthesis, etc., can solve the problems of accelerating the decomposition of hydroxyapatite and reducing biocompatibility, so as to increase the bending strength and fracture toughness, Good biocompatibility and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Use analytical pure H 3 PO 4 , 4MgCO 3 ·Mg(OH) 2 ·XH 2 O as the experimental material, press Mg 3 (PO 4 ) 2 The stoichiometric ratio is designed for the ingredients, the two are added with water until they are completely mixed and dried. After the synthesis is kept at 1100°C for 45 minutes, the synthesized powder is crushed and ground to obtain magnesium phosphate powder.

[0018] The prepared Mg 3 (PO 4 ) 2 Powder, 3mol% Y 2 O 3 Stable ZrO 2 Powder, Ca10(PO 4 ) 6 (OH) 2 Powder and polyethylene are used as raw materials, and a layered composite material of zirconium oxide, hydroxyapatite and magnesium phosphate is prepared according to the following method.

[0019] 3mol% Y 2 O 3 Stable ZrO 2 The powder is ball milled for 12 hours and dried to obtain the powder. The green body is obtained by dry pressing or grouting, and then subjected to 100MPa cold isostatic pressing to obtain the green body. The green body is sintered at 1550°C for 3 hours and cooled to room temperature nat...

Embodiment 2

[0024] Use analytical pure H 3 PO 4 , 4MgCO 3 ·Mg(OH) 2 ·XH 2 O as the experimental material, press Mg 3 (PO 4 ) 2 The stoichiometric ratio is designed for ingredients, the two are added with water until they are completely mixed and then dried. After the synthesis is kept at 1200°C for 90 minutes, the synthesized powder is crushed and ground to obtain magnesium phosphate powder.

[0025] The prepared Mg 3 (PO 4 ) 2 Powder, 3mol% Y 2 O 3 Stable ZrO 2 Powder, Ca10(PO 4 ) 6 (OH) 2 Powder and polypropylene are used as raw materials, and a layered composite material of zirconia, hydroxyapatite and magnesium phosphate is prepared according to the following method.

[0026] 3mol% Y 2 O 3 Stable ZrO 2 The powder is ball milled for 24 hours and dried to obtain the powder. The green body is obtained by dry pressing or grouting, and then subjected to 200MPa cold isostatic pressing to obtain the green body. The green body is sintered at 1550°C for 3 hours and cooled to room temperature naturall...

Embodiment 3

[0031] Use analytical pure H 3 PO 4 , 4MgCO 3 ·Mg(OH) 2 ·XH 2 O as the experimental material, press Mg 3 (PO 4 ) 2 The stoichiometric ratio is designed for the ingredients, the two are added with water until they are completely mixed and then dried. After the synthesis is kept at 1300°C for 60 minutes, the synthesized powder is crushed and ground to obtain magnesium phosphate powder.

[0032] The prepared Mg 3 (PO 4 ) 2 Powder, 3mol% Y 2 O 3 Stable ZrO 2 Powder, Ca 10 (PO 4 ) 6 (OH) 2 Powder and polystyrene are used as raw materials, and a layered composite material of zirconia, hydroxyapatite and magnesium phosphate is prepared according to the following method.

[0033] 3mol% Y 2 O 3 Stable ZrO 2 The powder is ball milled for 48 hours and dried to obtain the powder. The green body is obtained by dry pressing or grouting molding method, and then subjected to 300MPa cold isostatic pressing to obtain the green body. The green body is sintered at 1600°C for 3 hours and cooled to room t...

PUM

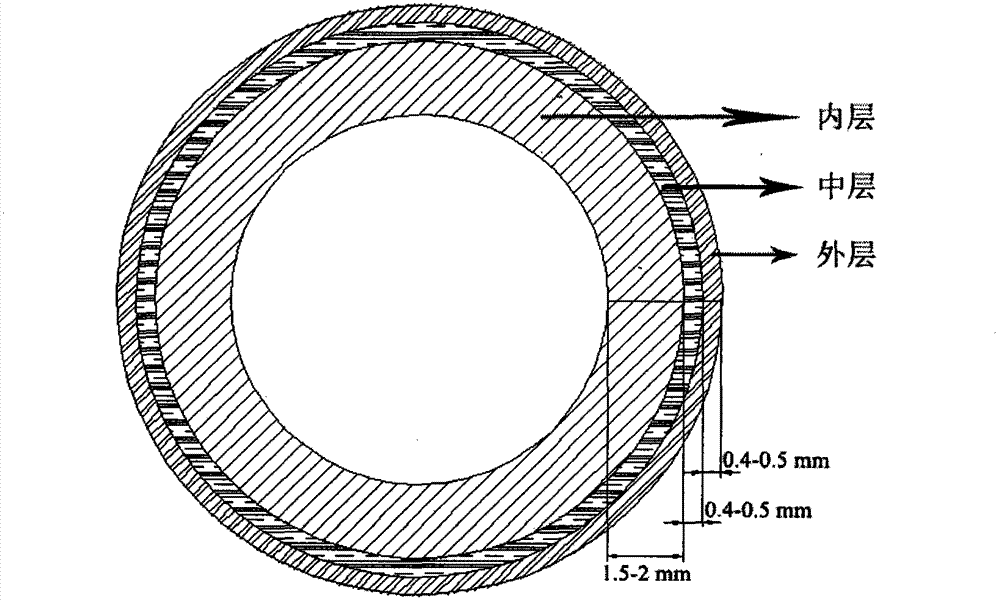

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com