Ultra-thick CrSiBN composite coating on surface of base body and preparation method thereof

A composite coating and substrate technology, applied in coatings, chemical instruments and methods, metal material coating technology, etc., can solve the problems of CrN coating corrosion and peeling, high friction and wear of CrN coating, fatigue wear, etc., to achieve reduction Small residual stress, high wear resistance, effect of improving hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In this embodiment, the base part is a diesel engine ductile iron piston ring, and the surface of the base is coated with an ultra-thick CrSiBN composite coating. The 2 μm thick CrN supporting layer on the surface of the transition layer, and the 20 μm thick CrSiBN anti-wear and lubricating layer on the surface of the CrN supporting layer. Among them, the Si content in the CrSiBN anti-wear lubricating layer is 4%, and the B content is 8%.

[0035] The preparation method of the ultra-thick CrSiBN composite coating on the surface of the above-mentioned substrate comprises the following steps:

[0036] 1. Spherical graphite cast iron piston rings were ultrasonically cleaned in acetone solution for 20 minutes, air-dried, then transferred to a mixed solution of sodium carbonate 30g / L and sodium phosphate 50g / L, treated at 60°C for 5 minutes, warm water ultrasonically cleaned, and nitrogen air-dried ;

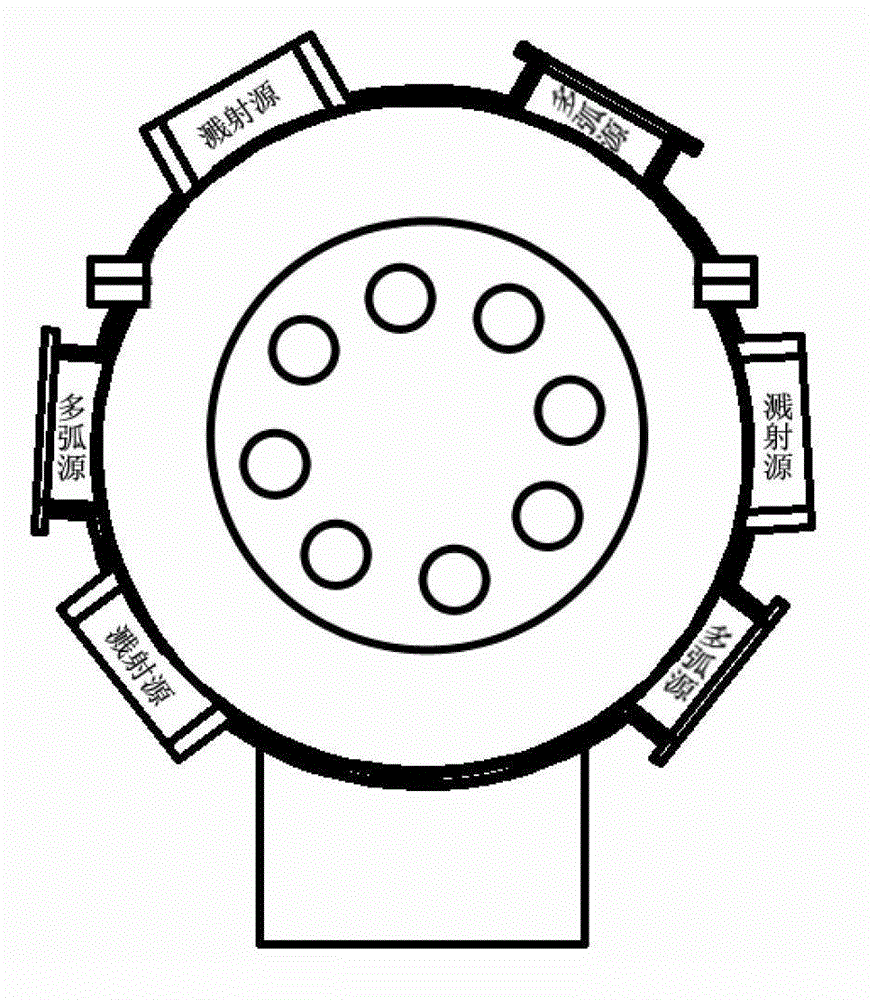

[0037] 2. The integrated equipment of straight tube magnetic filter multi...

Embodiment 2

[0044] In this embodiment, the base part is a large-sized 304 stainless steel gear in the disc polishing equipment, and the surface of the base is coated with an ultra-thick CrSiBN composite coating, and the ultra-thick CrSiBN composite coating is transitioned from a 0.5 μm thick Cr layer on the surface of the base. layer, a 2 μm thick CrN support layer on the surface of the Cr transition layer, and a 20 μm thick CrSiBN anti-wear lubrication layer on the surface of the CrN support layer. Among them, the Si content in the CrSiBN anti-wear lubricating layer is 8%, and the B content is 3%.

[0045] The preparation method of the ultra-thick CrSiBN composite coating on the surface of the above-mentioned substrate comprises the following steps:

[0046] 1. Ultrasonic clean the medium and large size 304 stainless steel gears of the disc polishing equipment in acetone solution for 20 minutes. Ultrasonic cleaning and nitrogen air drying;

[0047] 2. The integrated equipment of straig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com