Cement-base elastic waterproof composite material and preparation method thereof

A composite material and cement-based technology, applied in the field of waterproof materials, can solve the problems of short service life, complex construction methods and high comprehensive cost, and achieve the effects of saving construction period, simple construction and fast speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

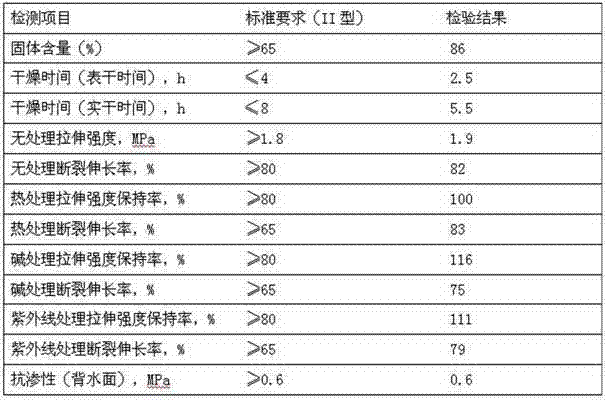

Image

Examples

Embodiment 1

[0044] The cement-based elastic waterproof composite material includes powder and liquid materials, and the weight ratio of powder and liquid materials is 2:1, wherein,

[0045] 1) The raw materials of the powder are

[0046] Portland cement 40kg,

[0047] Quartz sand 50kg,

[0048] Silica fume 2kg,

[0051] Hydroxypropyl methylcellulose 0.1kg;

[0052] 2) Each raw material of the liquid material is counted as

[0053] Vinyl acetate 25kg,

[0054] Acrylic acid 1kg,

[0055] Butyl acrylate 0.4kg,

[0056] Polyvinyl alcohol 2kg,

[0057] Emulsifier 1kg,

[0058] Dibutyl phthalate 2.5kg,

[0060] Ethanol 1kg,

[0061] Ammonium persulfate 0.04kg,

[0062] Deionized water 60kg,

[0063] Sodium bicarbonate 0kg.

[0064] Among them, Portland cement is 42.5R ordinary Portland cement, quartz sand has a particle size of 60 mesh and a silica content greater than or equal to 95%; silic...

Embodiment 2

[0071] The cement-based elastic waterproof composite material includes powder and liquid materials, and the weight ratio of powder and liquid materials is 2:1, wherein,

[0072] 1) The raw materials of the powder are calculated in parts by weight

[0073] Portland cement 50kg,

[0074] Quartz sand 55kg,

[0075] Silica fume 3kg,

[0076] Sodium silicate 0.3kg,

[0077] Sodium sulfate 0.4kg,

[0078] Hydroxypropyl methylcellulose 0.2kg;

[0079] 2) Each raw material of the liquid material is counted as

[0080] Vinyl acetate 30kg,

[0081] Acrylic 2kg,

[0082] Butyl acrylate 0.5kg,

[0083] Polyvinyl alcohol 3kg,

[0084] Emulsifier 1.5kg,

[0085] Dibutyl phthalate 3kg,

[0087] Ethanol 1.5kg,

[0088] Ammonium persulfate 0.05kg,

[0089] Deionized water 250kg,

[0090] Sodium bicarbonate 0.5kg.

[0091] Among them, Portland cement is 42.5R ordinary Portland cement, quartz sand has a particle size of 60 mesh and a silica content g...

Embodiment 3

[0098] The cement-based elastic waterproof composite material includes powder and liquid materials, and the weight ratio of powder and liquid materials is 2:1, wherein,

[0099] 1) The raw materials of the powder are calculated in parts by weight

[0100] Portland cement 45kg,

[0101] Quartz sand 52kg,

[0102] Silica fume 2.5kg,

[0103] Sodium silicate 0.25kg,

[0104] Sodium sulfate 0.35kg,

[0105] Hydroxypropyl methylcellulose 0.15kg;

[0106] 2) Each raw material of the liquid material is counted as

[0107] Vinyl acetate 27kg,

[0108] Acrylic acid 1.5kg,

[0109] Butyl acrylate 0.45kg,

[0110] Polyvinyl alcohol 2.5kg,

[0111] Emulsifier 1.25kg,

[0112] Dibutyl phthalate 2.75kg,

[0114] Ethanol 1.25kg,

[0115] Ammonium persulfate 0.045kg,

[0116] Deionized water 155kg

[0117] Sodium bicarbonate 0.2kg.

[0118] Among them, Portland cement is 42.5R ordinary Portland cement, quartz sand has a particle size of 60 mesh a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com