Method for efficiently separating acetylene gas

An acetylene gas, high-efficiency technology, used in adsorption purification/separation, chemical instruments and methods, hydrocarbon purification/separation, etc. and other problems, to achieve the effect of improving resource utilization, improving washing and dust removal effect, and high efficiency of trays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

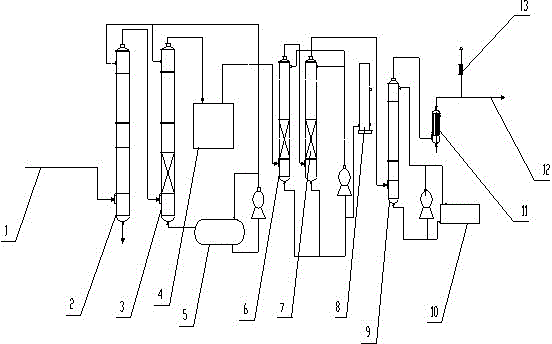

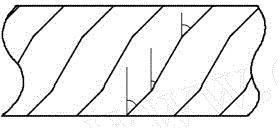

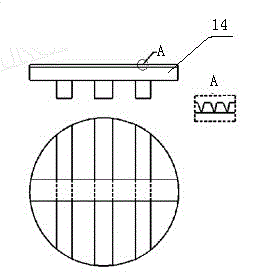

[0019] Refer to attached Figure 1-3 , the present embodiment comprises successively connected cooling tower 2, washing tower 3, Nassim unit 4, cleaning tower 6, neutralization tower 9 and cooler 11; packing 7 is provided in the cleaning tower; in the acetylene cleaning process, the acetylene The acetylene gas 1 produced by the generator is sent to the cooling tower for cooling. After cooling to remove supersaturated water, it is sent to the water washing tower for dust removal. The acetylene gas after dust removal is pressurized by the Nasim unit and then enters the cleaning tower. The gas is in reverse contact with the sodium hypochlorite solution sprayed down from the top of the cleaning tower in the packing layer in the cleaning tower, so that the sulfur and phosphorus impurities in the crude acetylene gas are oxidized into soluble sodium salts, and the acetylene gas after the sulfur and phosphorus impurities are removed Then enter the neutralization tower to neutralize wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com