Solvent or solvent composition for printing

A solvent composition, a technology of the composition, applied in the directions of printed circuit parts, applications, household appliances, etc., can solve the problems of insufficient pattern retention, reduced pattern retention, poor release, etc., to achieve excellent pattern retention, suppress Component deterioration, excellent quick-drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

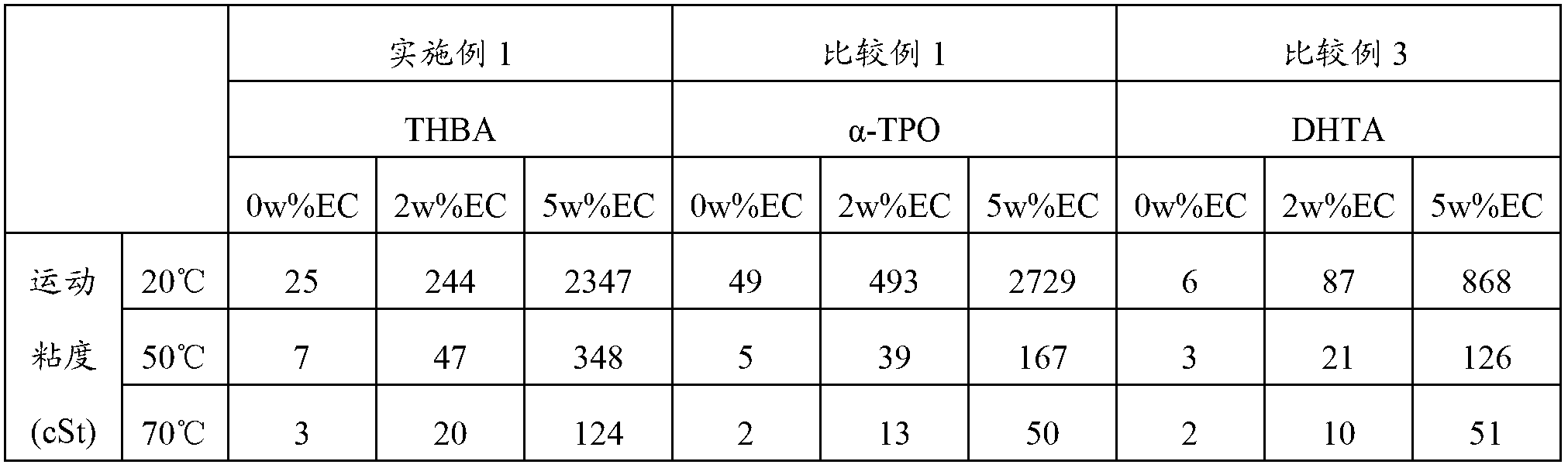

[0095] 1,2,5,6-tetrahydrobenzyl alcohol (trade name "THBA", manufactured by Daicel Chemical Co., Ltd., hereinafter sometimes referred to as "THBA") 19.80 g, 19.50 g, and ethyl cellulose (trade name "ETHOCEL", manufactured by DOW (KK), hereinafter sometimes referred to as "ETHOCEL") 0.20 g, 0.50 g, then stirred at 65 ° C and allowed to stand, It cooled naturally to 20 degreeC, and obtained paste composition (1-1) (ethylcellulose concentration: 2 weight% solution), (1-2) (ethylcellulose concentration: 5 weight% solution).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com