Large-scale integrated interconnection electromigration failure test method

A large-scale integrated interconnection and large-scale integration technology, applied in the field of testing, can solve the problems of high test cost, inability to obtain time information, low test efficiency, etc., and achieve the effect of improving test efficiency, reducing test time and reducing test cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

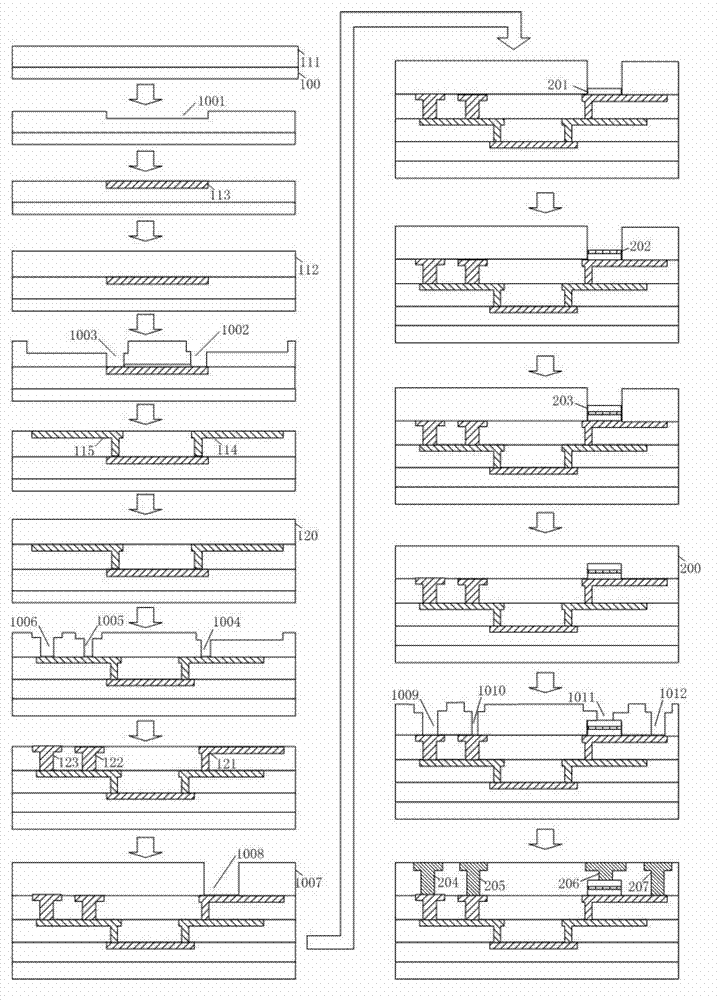

[0058] Such as figure 2 The material of the interconnection-antifuse unit shown is copper. The length of the first-level interconnection line 113 is 300 micrometers. The upper metal electrode 203 and the lower metal electrode 201 of the antifuse are made of titanium nitride with a thickness of 200 nanometers, and the material of the intermediate insulating medium 202 is silicon nitride with a thickness of 5 nanometers.

Embodiment 2

[0060] Such as figure 2 The material of the interconnection-antifuse unit shown is aluminum. The length of the first-level interconnection line 113 is 350 micrometers. The material of the upper metal electrode 203 and the lower metal electrode 201 of the antifuse is titanium tungsten with a thickness of 250 nanometers, and the material of the intermediate insulating medium 202 is amorphous silicon with a thickness of 60 nanometers.

Embodiment 3

[0062] Such as figure 2 The material of the interconnection-antifuse unit shown is copper. The length of the first-level interconnection line 113 is 400 micrometers. The material of the upper metal electrode 203 and the lower metal electrode 201 of the antifuse is titanium nitride with a thickness of 300 nanometers, and the material of the intermediate insulating medium 202 is a hydrogen-containing amorphous carbon film doped with nitrogen and fluorine elements with a thickness of 25 nm. Nano.

[0063] The performance of the present invention can be specified by the following tests.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com