Double-layer walled microporous self-assembled material with fluorescent recognition effect and preparation method thereof

A fluorescent recognition and self-assembly technology, applied in the direction of luminescent materials, chemical instruments and methods, zinc organic compounds, etc., can solve problems such as poor operability, weakened fluorescence of adsorbents, and many external factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

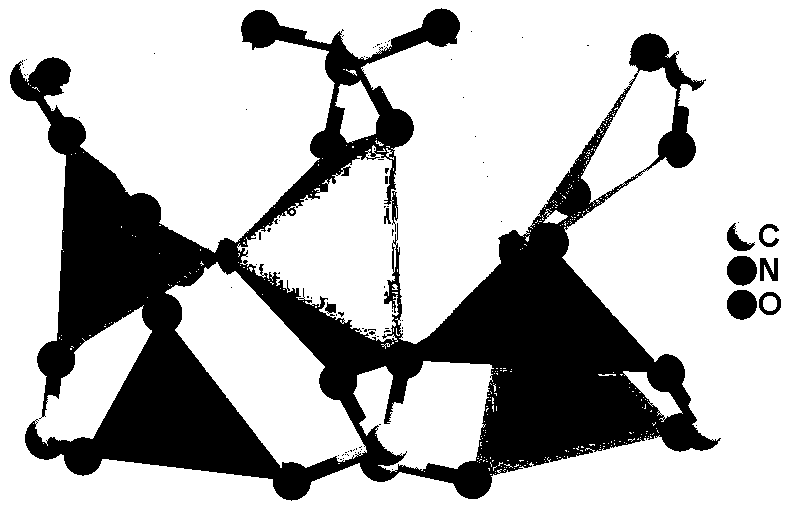

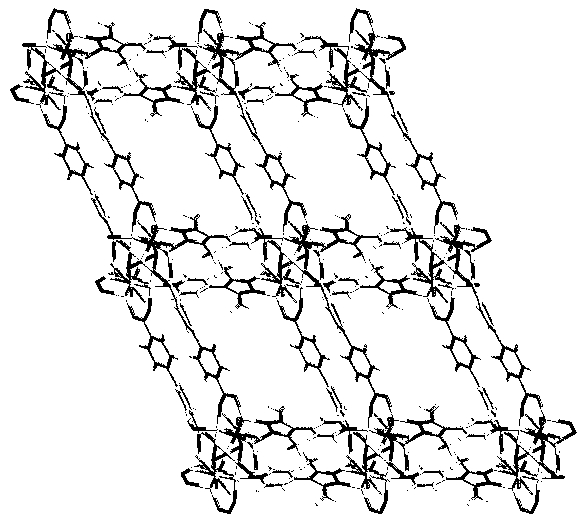

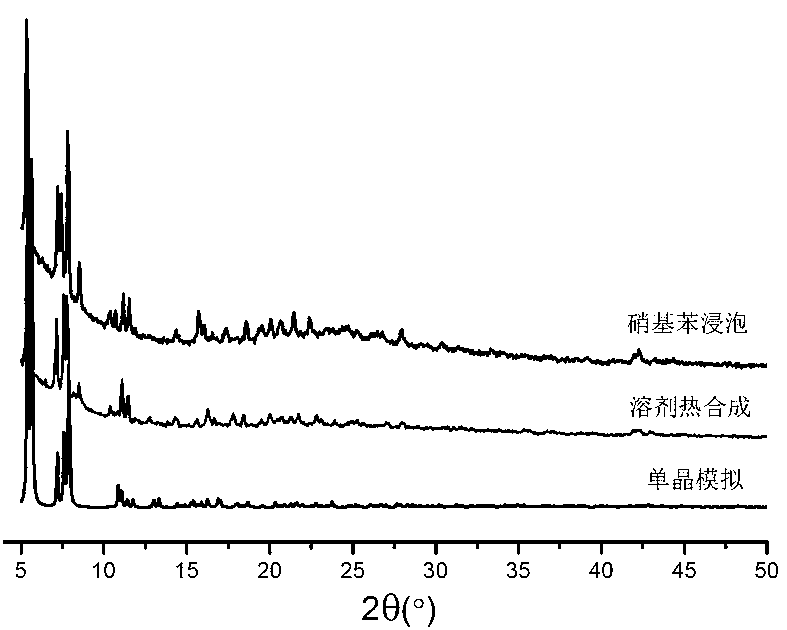

Embodiment 1

[0024] Add 0.208 g of zinc nitrate, 0.097 g of 4,4'-biphenyl dicarboxylic acid and 0.034 g of 4-(3,5-dimethyl-1H-pyrazole-4-)pyridine to 10 ml of N,N'-bis In the ethyl formamide solvent, after stirring at room temperature for 30 minutes, a white emulsion was obtained, which was moved to a stainless steel reactor lined with polytetrafluoroethylene, and reacted at 140 ° C for about 72 hours, and then naturally cooled to room temperature ( The preferred cooling rate is about 5°C / h), filter to obtain light yellow crystals, wash the crystals three times with N,N'-diethylformamide and acetone, and dry them in an oven at 60°C for 30 minutes to obtain the micropores self-assembling materials.

Embodiment 2

[0026]Add 0.198 g of zinc acetate, 0.097 g of 4,4'-diphenyldicarboxylic acid, and 0.034 g of 4-(3,5-diethyl-1H-pyrazole-4-)pyridine into 10 mL of N,N'- In dimethylacetamide solvent, stir at room temperature for 10 minutes, add 1 to 5 drops of nitric acid and continue stirring for 20 minutes. Move it to a stainless steel reactor lined with polytetrafluoroethylene, react at 60°C for about 8 hours, then cool naturally to room temperature, filter to obtain light yellow crystals, and use N,N'-dimethylacetamide, acetone The crystals were washed three times respectively, and vacuum-dried for 30 minutes to obtain the microporous self-assembled material.

Embodiment 3

[0028] Add 0.104 g of zinc nitrate, 0.048 g of 4,4'-biphenyldicarboxylic acid, and 0.018 g of 4-(3,5-dimethyl-1H-pyrazole-4-)pyridine to 1 mL of N,N'- Dimethylformamide and 9 mL of N,N'-diethylformamide solvent, stirred at room temperature for 500 minutes. Move it to a stainless steel reactor lined with polytetrafluoroethylene, react at 180°C for about 120 hours, then cool to room temperature at a rate of about 5°C / h, filter to obtain light yellow crystals, and use N,N'- The crystals were washed three times with dimethylformamide and acetone respectively, and dried in an oven at 80° C. for 30 minutes to obtain the microporous self-assembled material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com