Coal chemical poly-generation process and system

A technology of polygeneration and coal chemical industry, applied in the chemical industry, organic chemistry, hydrocarbons, etc., can solve the problem of high energy grade, achieve high-efficiency thermal conversion, reduce energy consumption, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

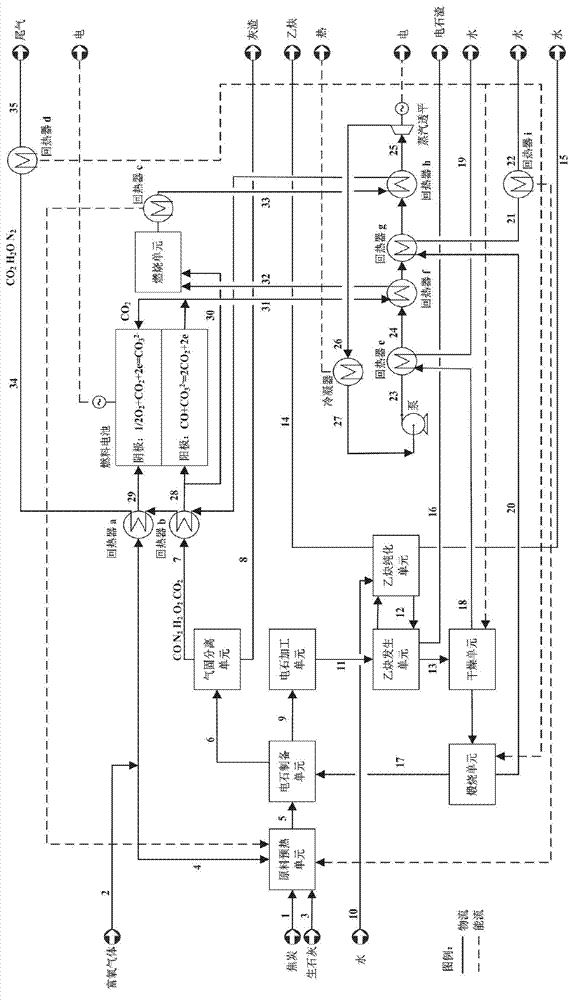

[0027] Such as figure 1 As shown, the coal chemical polygeneration process and system are composed of a low-rank coal-based oxythermal calcium carbide acetylene production system, a fuel cell cycle of calcium carbide furnace gas and oxygen-rich gas, a steam Rankine cycle, and process heat recovery.

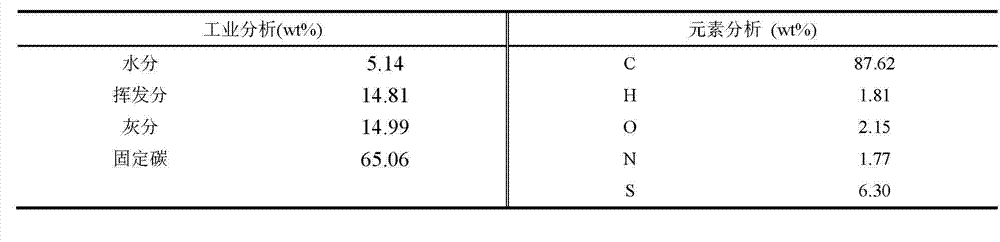

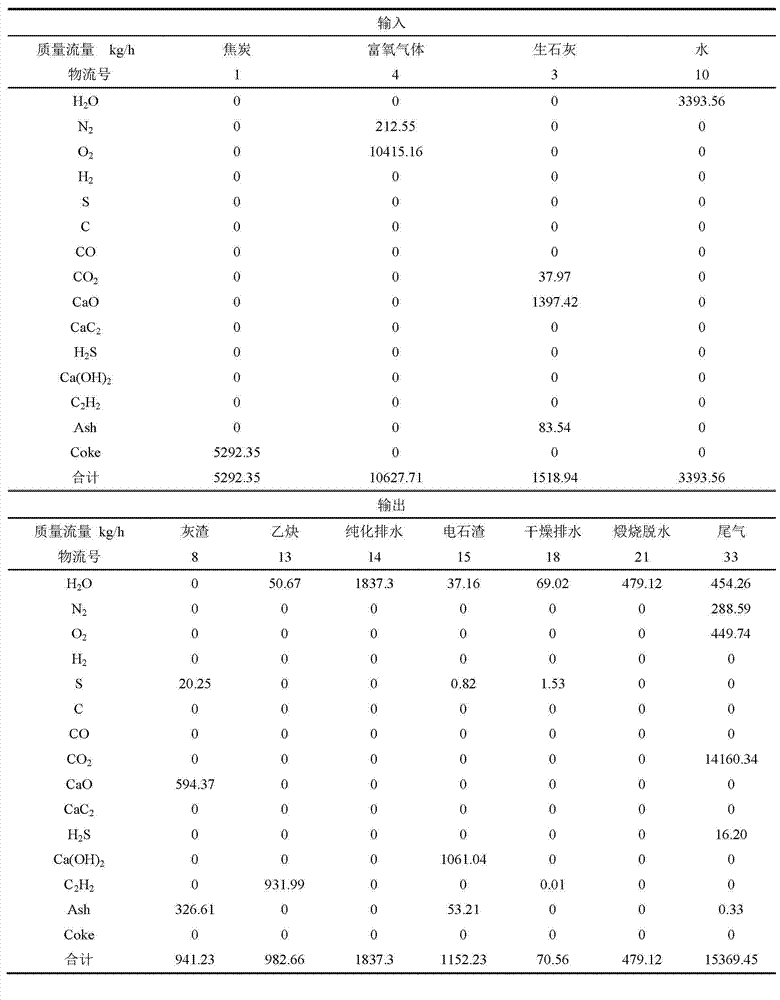

[0028] Carbide acetylene production system: Coke 1 (its composition is shown in Table 1), quicklime 3 and oxygen-enriched gas 4 after upgrading and conversion of low-rank coal are used to enter the raw material preheating unit respectively. The heat of the raw material preheating unit comes from the regenerator c. The heat required for preheating the oxygen-enriched gas 4 of the raw material preheating unit is provided by the regenerator i. The raw material preheating unit can preheat the raw material to 1000°C. Raw material 5 is burned in the calcium carbide preparation unit first, and part of the coke is self-heated. After the reaction temperature reaches 2000°C, the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com