Method for preparing lycoypene microcapsule

A technology of lycopene and microcapsules, which is applied in the field of preparation of lycopene microcapsules, can solve the problems that it is difficult to ensure the long-term stability of the content of water-soluble active ingredients in lycopene microcapsules, and achieve improved water solubility and stability , the effect of preventing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1. Core material preparation: Add 8.5g lycopene to 12.5ml salad oil, add 0.7g sucrose ester as emulsifier, stir evenly, this is oil phase A.

[0018] 2. Wall material preparation: take gelatin, broken ganoderma lucidum spore powder, sucrose, and skimmed milk powder (that is, the wall material raw material) with a weight ratio of 1:1:1:1.4, add distilled water 4 times the amount of the wall material raw material, and heat to 45 °C, stir to make it into a uniform suspension, which is oil phase B.

[0019] 3. Homogeneous emulsification: Slowly add the mixture of oil phase A and oil phase B into the water while stirring. The weight ratio of water to oil phase (that is, the sum of oil phase A and oil phase B) is 3:5, and then Place in a colloid mill and grind at 6000 rpm for 30 minutes to disperse lycopene evenly in the wall material to obtain a homogeneous emulsion.

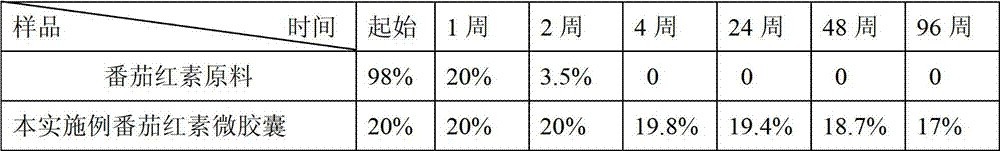

[0020] The homogenized emulsion is spray-dried to obtain powdery lycopene microcapsules. The control cond...

Embodiment 2

[0029] 1. Core material preparation: Add 8g lycopene to 12.5ml salad oil, add 0.7g sucrose ester as emulsifier, stir well, this is oil phase A.

[0030] 2. Wall material preparation: Take gelatin, broken ganoderma lucidum spore powder, sucrose, and skimmed milk powder (that is, the wall material raw material) with a weight ratio of 1:1:1:1.2, add distilled water that is 3 times the amount of the wall material raw material, and heat to 45 °C, stir to make it into a uniform suspension, which is oil phase B.

[0031] 3. Homogeneous emulsification: Slowly add the mixture of oil phase A and oil phase B while stirring in the water. The weight ratio of water and oil phase is 3:5, and then put it in the colloid mill, under the condition of 8000 rpm Down grinding, the grinding time is 25min, that is, the lycopene is evenly dispersed in the wall material to obtain a homogeneous emulsion.

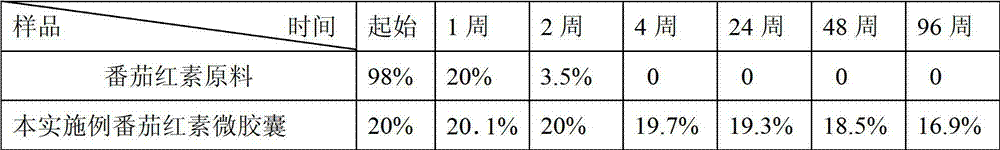

[0032] The homogenized emulsion is spray-dried to obtain a powdered lycopene product. The contro...

Embodiment 3

[0038] 1. Core material preparation: Add 9g lycopene to 12.5ml salad oil, add 0.7g sucrose ester as emulsifier, stir well, this is oil phase A.

[0039] 2. Wall material preparation: Take gelatin, broken ganoderma lucidum spore powder, sucrose, and skimmed milk powder (that is, the wall material raw material) with a weight ratio of 1:1:1:1.6, add 5 times the amount of distilled water to the wall material raw material, and heat to 40 °C, stir to make it into a uniform suspension, which is oil phase B.

[0040]3. Homogeneous emulsification: Slowly add the mixture of oil phase A and oil phase B while stirring in water. The weight ratio of water and oil phase is 3.5:5, and then put it in a colloid mill, at 5000 rpm Grinding at the bottom, the grinding time is 35min, and the lycopene is evenly dispersed in the wall material to obtain a homogeneous emulsion.

[0041] The homogenized emulsion is spray-dried to obtain a powdery lycopene product. The control conditions of spray dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com