Floating type BiVO4/floating bead composite photocatalyst and preparation method and application thereof

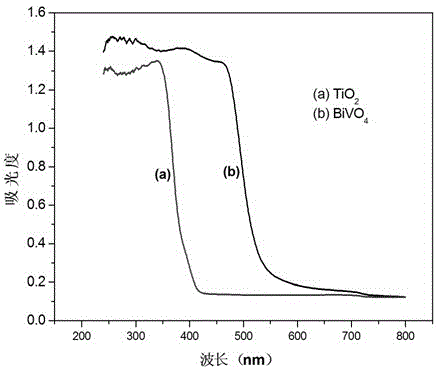

A catalyst and floating technology, applied in the field of visible light catalysts, can solve the problems of difficult separation and recovery, waste of resources, etc., and achieve the effects of being easy to accept light, improving efficiency, and being easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

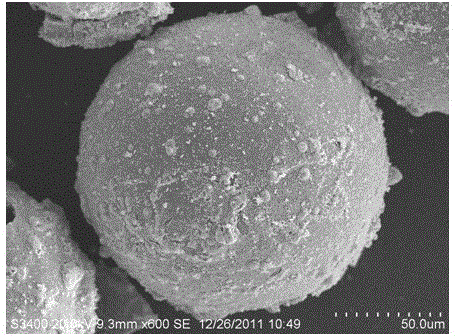

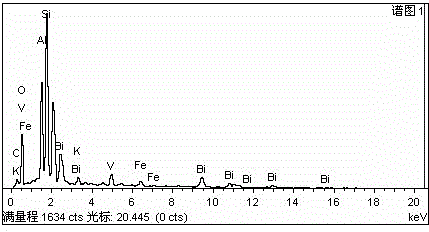

[0024] 1) Pretreatment of floating beads: add fly ash floating beads to 10% nitric acid solution, ultrasonically clean at room temperature for 1 hour, filter, and dry at 120°C;

[0025] 2) Add the silane coupling agent KH550 into the mixed solvent of ethanol and ultrapure water, the volume ratio of the coupling agent to the mixed solvent is 1:100, stir and hydrolyze at room temperature, then add the floating beads obtained in step 1), and stir to react 8h, filter out the floating beads, wash them alternately with ethanol and ultrapure water, and dry them in a drying oven at 120°C;

[0026] 3) Weigh 4.85g of bismuth nitrate pentahydrate and dissolve it in 40mL of glacial acetic acid, then add 0.2g of polyethylene glycol 10000, stir to fully dissolve to obtain solution A; quickly pipette 2.35mL of isopropoxy vanadium oxide, dropwise Add to 20mL acetylacetone, stir vigorously to obtain solution B. Slowly add solution B to solution A with a syringe, and stir for 1 hour to obtain ...

Embodiment 2

[0035] 1) Pretreatment of floating beads: add fly ash floating beads to 10% nitric acid solution, ultrasonically clean at room temperature for 2 hours, filter, and dry at 120°C;

[0036] 2) Add the silane coupling agent KH550 into the mixed solvent of ethanol and ultrapure water, the volume ratio of the coupling agent to the mixed solvent is 1:200, stir and hydrolyze at room temperature, then add the floating beads obtained in step 1), and stir to react 6h, filter out the floating beads, wash them alternately with ethanol and ultrapure water, and dry them in a drying oven at 120°C;

[0037] 3) Weigh 4.85g of bismuth nitrate pentahydrate and dissolve it in 40mL of glacial acetic acid, then add 0.15g of polyethylene glycol 10000, stir to fully dissolve to obtain solution A; quickly pipette 2.35mL of isopropoxyvanadium oxide, dropwise Add to 20mL acetylacetone, stir vigorously to obtain solution B. Slowly add solution B to solution A with a syringe, and stir for 1 hour to obtain...

Embodiment 3

[0043] 1) Pretreatment of floating beads: add fly ash floating beads to 10% nitric acid solution, ultrasonically clean at room temperature for 2 hours, filter, and dry at 120°C;

[0044] 2) Add the silane coupling agent KH550 into the mixed solvent of ethanol and ultrapure water, the volume ratio of the coupling agent to the mixed solvent is 1:150, stir and hydrolyze at room temperature, then add the floating beads obtained in step 1), and stir to react 8h, filter out the floating beads, wash them alternately with ethanol and ultrapure water, and dry them in a drying oven at 120°C;

[0045] 3) Weigh 2.43g of bismuth nitrate pentahydrate and dissolve it in 20mL of glacial acetic acid, then add 0.15g of polyethylene glycol 10000, stir to fully dissolve to obtain solution A; quickly pipette 1.20mL of isopropoxyvanadium oxide, drop by drop Added into 12mL acetylacetone, stirred vigorously to obtain solution B. Slowly add solution B to solution A with a syringe, and stir for 1 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com