Antimicrobial modified polyvinylidene fluoride membrane and preparation method thereof

A polyvinylidene fluoride film and modification technology, which is applied in the field of antibacterial modified polyvinylidene fluoride film and its preparation, achieves the effects of obvious killing effect, easy operation, and improved hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Preparation of unmodified pure polyvinylidene fluoride film: mix 8.5g polyvinylidene fluoride and 1.5g polyethylene glycol (M6000) in 40mL solvent dimethylacetamide, stir well at 60°C until The polyvinylidene fluoride is completely dissolved to obtain a uniform casting solution. At 60°C, let stand at constant temperature for defoaming for 12 hours. Pour the casting solution on a glass plate, scrape it into a flat film with a thickness of about 250 microns, put it in deionized water at room temperature, solidify and form it, and after the film falls off the glass plate, the unmodified film can be obtained. Pure polyvinylidene fluoride membrane.

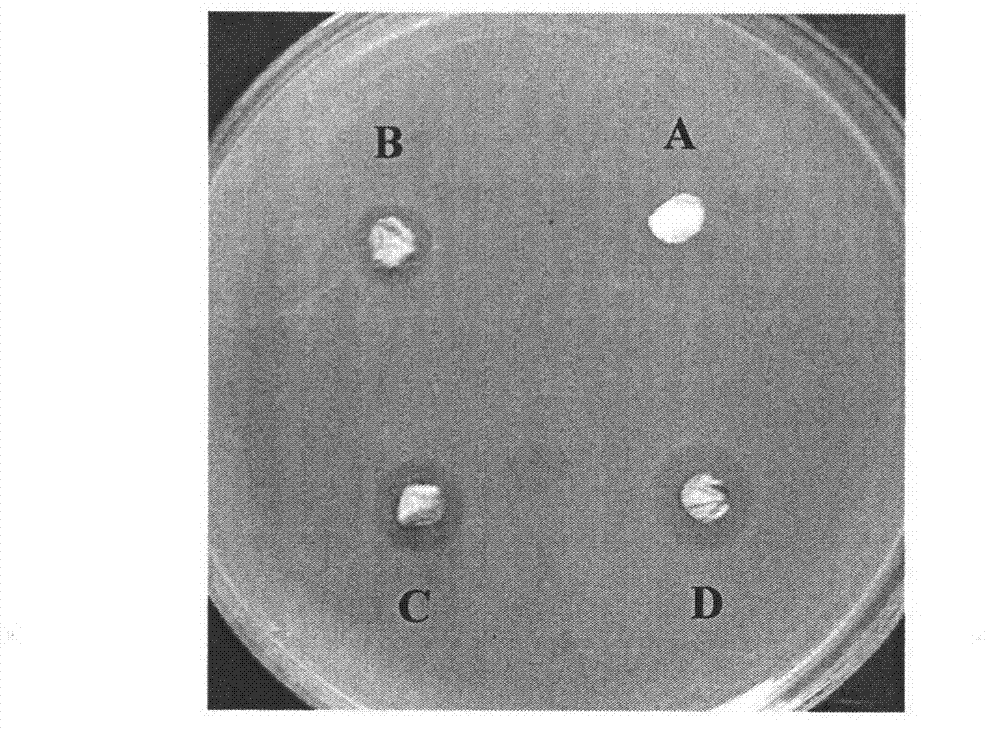

[0023] Antibacterial performance test: the antibacterial performance of the film obtained in this example against Staphylococcus aureus was measured by the zone of inhibition method, and the operation was as follows. In the ultra-clean workbench, draw 100 μL of Staphylococcus aureus suspension and mix with 15 mL of beef extrac...

Embodiment 2

[0026] Preparation of silver-loaded molecular sieve Ag-X: 13X molecular sieve was dried to constant weight and ground into powder. Add 1 g of dry 13X molecular sieve to 10 mL of AgNO with a concentration of 0.1 mol / L 3 In the solution, stir for 5 hours at 60°C in the dark, filter with suction, wash until there is no silver ion in the filtrate (dilute hydrochloric acid solution is dripped without precipitation), and dry at 60°C to obtain the silver-loaded molecular sieve Ag-X.

[0027] Preparation of antibacterial modified polyvinylidene fluoride membrane: Mix 0.5g Ag-X molecular sieve micropowder with 8.5g polyvinylidene fluoride, 1.5g polyethylene glycol (M6000) in 40mL solvent dimethylacetamide, at 60°C Stir well until the polyvinylidene fluoride is completely dissolved to obtain a uniform casting solution. At 60°C, let stand at constant temperature for defoaming for 12 hours. Pour the casting solution on a glass plate, scrape it into a flat film with a thickness of about ...

Embodiment 3

[0030] Preparation of silver-loaded molecular sieve Ag-X: Add 1.0 g of dry 13X molecular sieve to 10 mL of AgNO with a concentration of 0.5 mol / L 3 In the solution, stir at 60° C. in the dark for 5 hours, filter with suction, wash, and dry at 60° C. to obtain silver-loaded molecular sieve Ag-X.

[0031] Preparation of antibacterial modified polyvinylidene fluoride membrane: 1.0g Ag-X molecular sieve powder, 8.5g polyvinylidene fluoride, 1.5g polyethylene glycol (M6000) were mixed in 40mL solvent dimethylacetamide, at 60°C Stir thoroughly until the polyvinylidene fluoride is completely dissolved to obtain a uniform casting solution. At 60°C, let stand at constant temperature for defoaming for 12 hours. Pour the casting solution on a glass plate, scrape it into a flat film with a thickness of about 250 microns, put it in deionized water at room temperature, solidify and form it, and after the film falls off the glass plate, you can get the antibacterial modified polyphenylene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com