Stripping liquid for plasma display screen as well as preparation method and application of stripping liquid

The technology of stripping solution and deionized water is applied in the field of plasma display stripping solution and its preparation and application. Corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

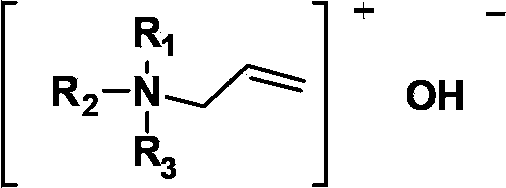

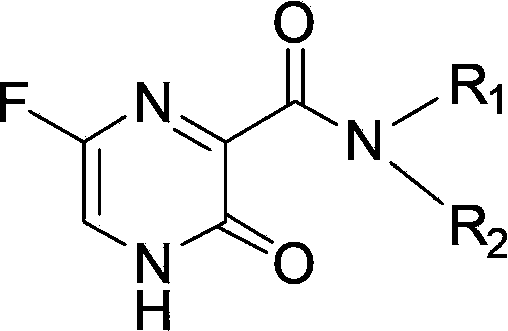

[0068] Trimethylallyl ammonium hydroxide (AM1) 5 grams, amide compound 6-fluoro-3-oxo-3,4-hydropyrazine-2-carboxamide (PCA) 2 grams; glycol ethers 15 grams of water-soluble organic solvent propylene glycol (PG), 0.5 grams of preservative sorbitol (SRB) and 77.5 grams of deionized water were mixed at room temperature by stirring and oscillating to obtain the plasma display screen stripping solution provided by the present invention.

[0069] According to the exact same steps as in Example 1 above, only the names and dosages of the components used are replaced as shown in Table 1 to obtain Examples 2-5. Exactly the same steps, the components of different mass percentages were selected for comparison, and the names and amounts of each component were also listed in Table 1. The peeling effect is as follows figure 1 shown.

[0070] Table 1, the composition list of the stripping solution

[0071]

[0072] Note:

[0073] AM1: Trimethylallyl Ammonium Hydroxide

[0074] AM2: Tr...

Embodiment 6

[0086] Trimethylallyl ammonium hydroxide (AM1) 5 grams, amide compound 6-fluoro-3-oxo-3,4-dihydropyrazine-2-carboxamide (PCA) 5 grams; glycol ether 10 grams of water-soluble organic solvent propylene glycol (PG), 0.5 grams of preservative sorbitol (SRB) and 79.5 grams of deionized water were mixed at room temperature by stirring and shaking to obtain the plasma display stripping liquid provided by the present invention.

[0087] According to the exact same steps as in Example 6 above, only the names and amounts of the components used are replaced as shown in Table 3 to obtain Examples 7-10. Exactly the same steps, the components of different mass percentages are selected for comparison, and the names and amounts of each component are also listed in Table 3.

[0088] Table 3. List of stripping liquid composition

[0089]

[0090]

[0091] Note:

[0092] AM1: Trimethylallyl Ammonium Hydroxide

[0093] AM2: Triethylallyl Ammonium Hydroxide

[0094] AM3: Tripropylallyl A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com