Calcium ferroaluminate compound, cement admixture and process for producing same, and cement composition

A technology of calcium ferric aluminate and compound, applied in iron compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problem of not confirming the effect of nitrite acid resistance, etc., and achieve excellent anti-rust effect, infiltration inhibition, The effect of sufficient operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0063] (specification of the crystal structure of the compound)

[0064] Synthetic calcium ferrite (C 2 F), calcium aluminum ferrite (C 4 AF, C 6 A 2 F, C 6 AF 2 ), calcium aluminate, calcium aluminate (CA 2 ).

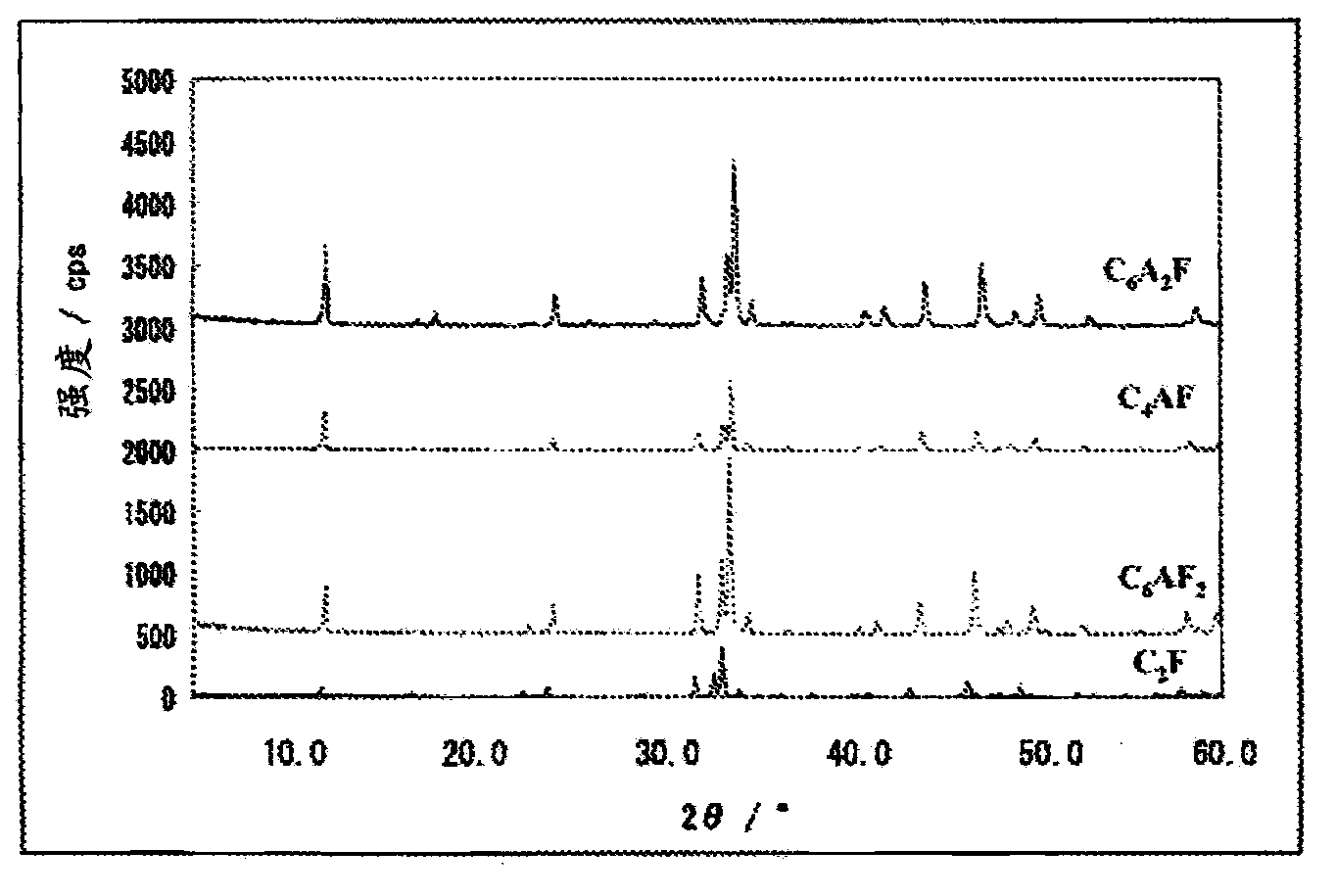

[0065] figure 1 Show calcium ferrite (C 2 F) and calcium aluminum ferrite (C 4 AF, C 6 A 2 F, C 6 AF 2 ) XRD measurement result. Depend on figure 1 It can be seen that these have the same crystal structure.

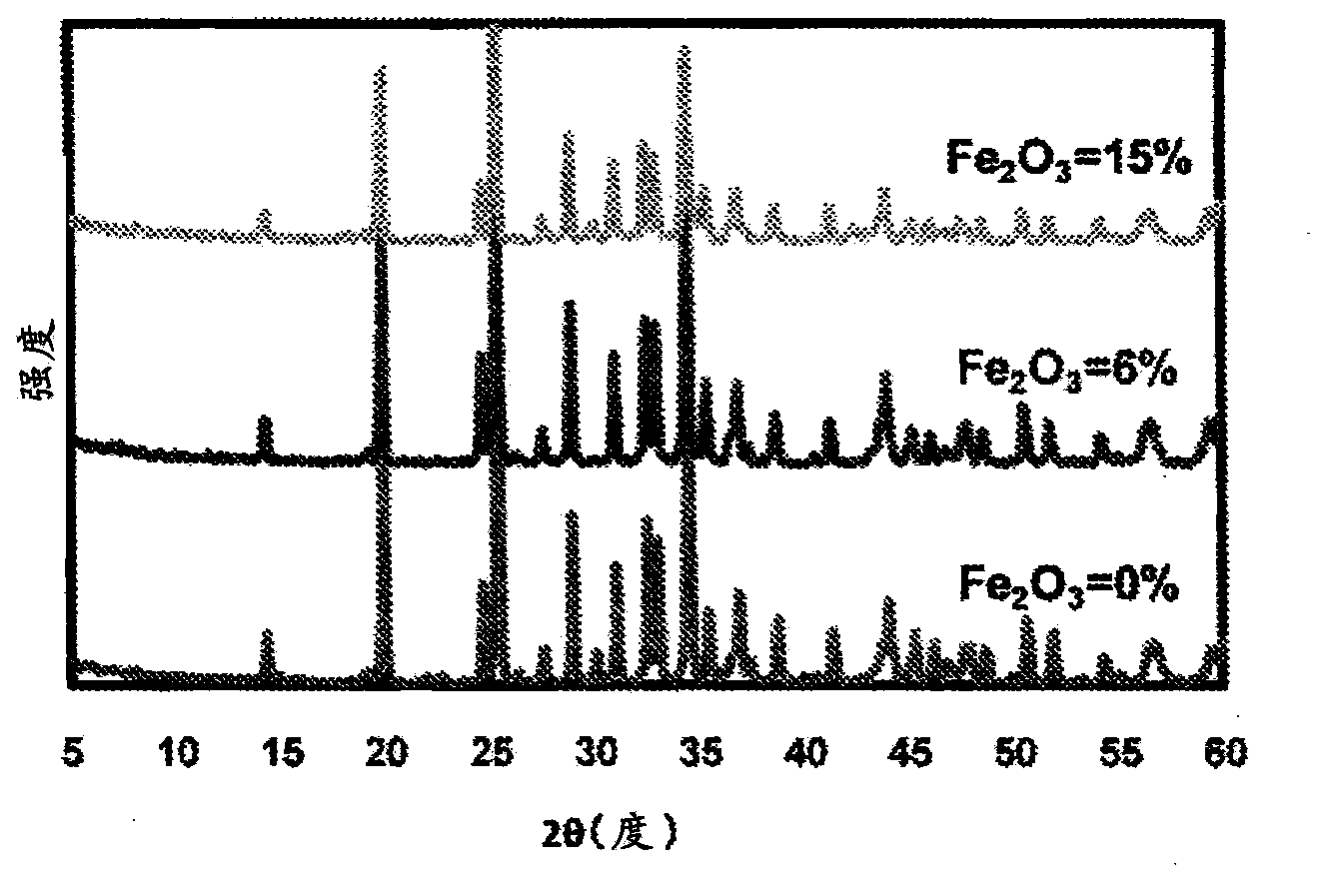

[0066] on the other hand, figure 2 Calcium aluminate and calcium aluminate (CA 2 ) XRD measurement result. It can be seen that calcium aluminum ferrite maintains CA 2 While the structure, Fe 2 o 3 solid solution. In addition, if Fe 2 o 3 If it exceeds 15%, there will be no solid solution, and the precipitation of magnetite can be seen. It has been confirmed from the above that calcium aluminate ferrite is different from the previously known CaO-Al 2 o3 -Fe 2 o 3 The calcium aluminum ferrite system compound is a completely different co...

experiment example 1

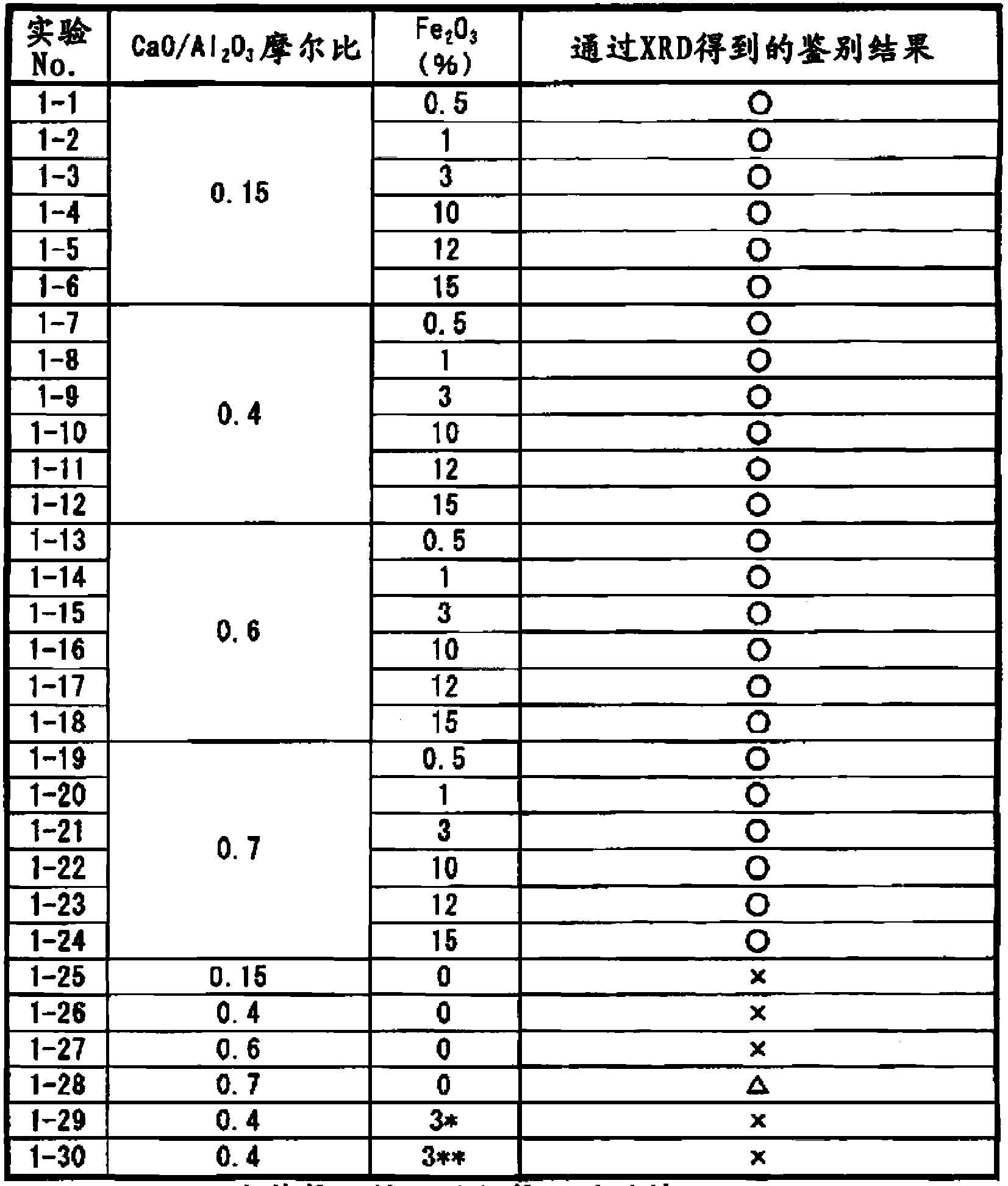

[0068] Calcium carbonate of reagent grade 1 and aluminum oxide of reagent grade 1 were compounded so that the molar ratios shown in Table 1 were obtained in terms of oxides, and iron oxide of reagent grade 1 was adjusted to the ratio shown in Table 1 with respect to the complex. Fe 2 o 3 The method of content is compounded and fired in an electric furnace. CaO / Al 2 o 3 The substance with a molar ratio of 0.7 is at 1400°C, CaO / Al 2 o 3 The substance with a molar ratio of 0.6 is at 1450°C, CaO / Al 2 o 3 The substance with a molar ratio of 0.4 is at 1500°C, CaO / Al 2 o 3 The substances with a molar ratio of 0.15 were respectively calcined at 1550° C. for 3 hours, and then slowly cooled to synthesize them. All Blaine values adjusted to 4,000cm 2 / g. In addition, for comparison, for the case of not adding iron oxide, containing SiO 2 case, containing R 2 The case of O is also synthesized in the same manner. The presence or absence of unreacted substances was evaluated...

experiment example 2

[0078] Cement compositions were prepared by mixing 7 parts of the CFA compounds shown in Table 2 with 100 parts of cement compositions consisting of cement and CFA compounds, and mortars with a water / binder ratio of 0.5 were prepared in accordance with JIS R 5201. Using this mortar, setting time, antirust effect, compressive strength, chloride penetration depth, Ca ion infiltration, and sulfate resistance were investigated. The results are also listed in Table 1. In addition, the test was performed at an ambient temperature of 30°C.

[0079]

[0080] CFA compound A: mix the calcium carbonate of the reagent grade 1 with the alumina of the reagent grade 1 in a specified ratio, and use Fe 2 o 3 The iron oxide of grade 1 of the reagent is mixed so that the content becomes 3%, and it is synthesized by firing in an electric furnace at 1550°C in the same manner as in Experimental Example 1, and then slowly cooling CaO / Al 2 o 3 Molar ratio 0.1, Blaine value 4,000cm 2 / g

[008...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com