Preparation method of preservative film

A technology of fresh-keeping film and nuclear pore film, which is applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problems of short shelf life, difficult control of gas adjustment amount, low air permeability of packaging film, etc. Shelf life, reducing anaerobic respiration and carbon dioxide damage, preventing condensation and external microbial infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The embodiment of the invention discloses a method for preparing a plastic wrap, comprising:

[0026] Heavy ions irradiate polymer films to obtain latent track films;

[0027] Coating an adhesive on the surface of the sneak track membrane to obtain an intermediate nuclear pore membrane, the part of the intermediate nuclear pore membrane that is not coated with an adhesive forms an etching part, and the part coated with an adhesive forms an adhesive part ;

[0028] Etching the intermediate nuclear pore membrane in an etching solution to obtain a nuclear pore membrane;

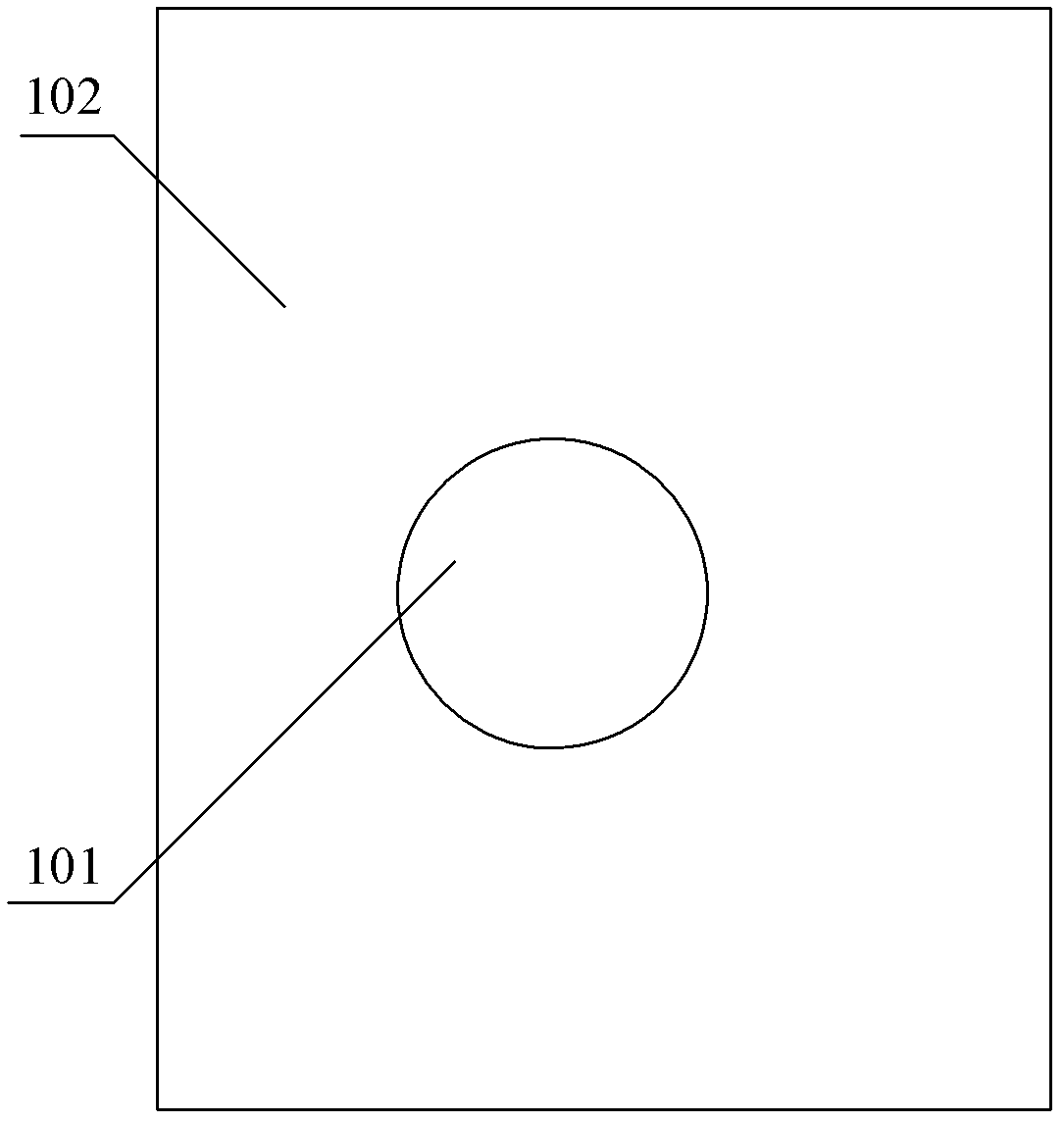

[0029] Coating an adhesive on the surface of the intermediate base film, and partially hollowing out the part covered with the adhesive to obtain a base film;

[0030] The nuclear pore membrane is bonded to the hollow part of the base membrane.

[0031] It can be seen from the above scheme that the preparation method provided by the present invention is obtained by firstly preparing the nuclear pore me...

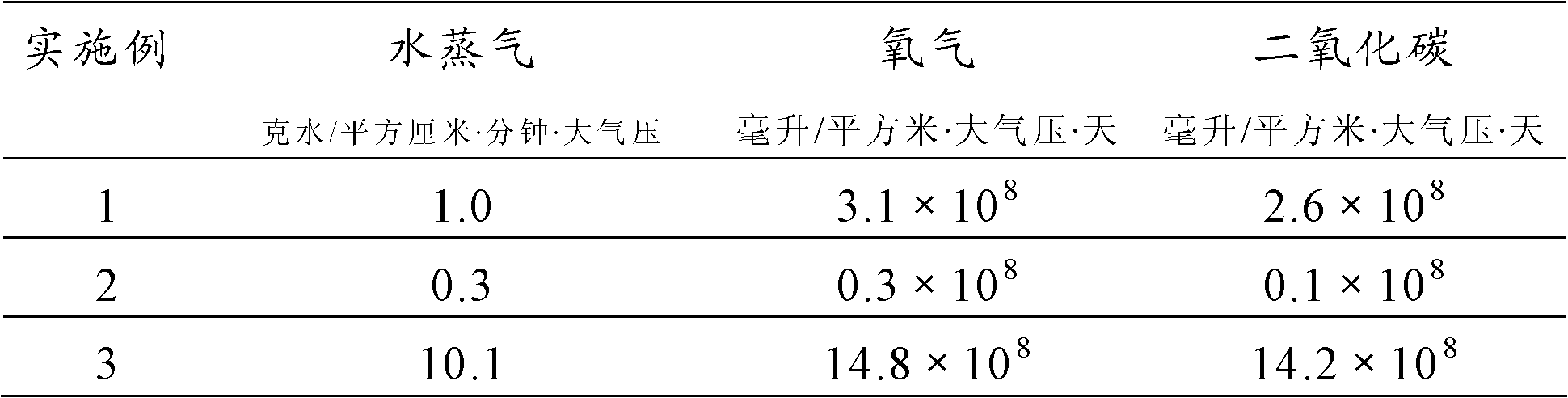

Embodiment 1

[0052] Embodiment 1 prepares fresh-keeping film for apple packaging

[0053] 1. The 22MeV / nucleon Ar-40 accelerated by a high-energy accelerator irradiates a PET film with a thickness of 25μm for 1s, forming a latent track density of 10 7 / m 2 Submerged track membrane;

[0054] 2. Transfer the hot melt adhesive to the submerged track film by gravure printing, the part covered with hot melt adhesive on the submerged track film forms the bonding part, and the part not covered with the hot melt adhesive forms the etched part to obtain Intermediate nuclear pore membrane.

[0055] 3. Etching the intermediate nuclear pore membrane obtained in step 2 in a 7M sodium hydroxide solution at 80°C for 20 minutes, the etched part forms micropores with a pore diameter of 1 micron to obtain a nuclear pore membrane;

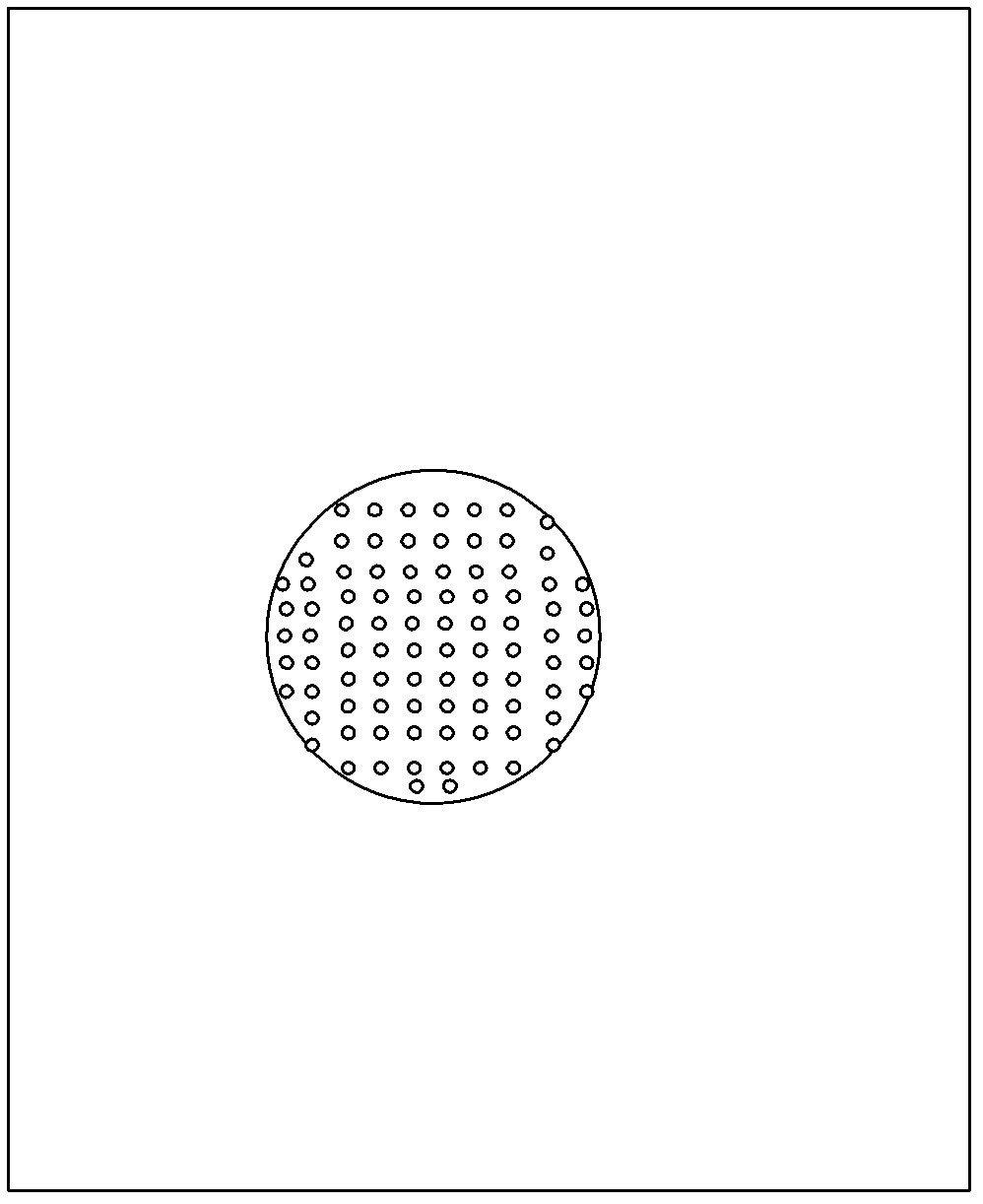

[0056] 4. Transfer the hot melt adhesive to the base film polyethylene film by positioning printing, and then partially hollow out the hot melt adhesive, and distribute 6 hole...

Embodiment 2

[0058] Embodiment 2 prepares the fresh-keeping film of pork packaging

[0059] 1. The PET film with a thickness of 20 μm is irradiated with 5 MeV / nucleon S-32 accelerated by a high-energy accelerator to form a latent track density of 10 8 / m 2 Submerged track membrane;

[0060] 2. Transfer the hot melt adhesive to the submerged track film by gravure printing, the part covered with hot melt adhesive on the submerged track film forms the bonding part, and the part not covered with the hot melt adhesive forms the etched part to obtain Intermediate nuclear pore membrane.

[0061] 3. Etching the intermediate nuclear pore membrane obtained in step 2 in 50° C., 7M sodium hydroxide solution for 10 minutes, the etched part forms micropores with a pore diameter of 0.1 micron, and obtains a nuclear pore membrane;

[0062] 4. Transfer the hot melt adhesive onto the base film PE film by positioning printing, and then partially hollow out the place where the hot melt adhesive is, and dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com