Method for making hydrogen through pyrolytic gasification of biomass and coke under microwave field

A technology of pyrolysis gasification and biomass, applied in chemical instruments and methods, hydrogen, hydrogen separation, etc., can solve the problems of low hydrogen yield and high tar content, and achieve reduced tar production, short reaction time and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

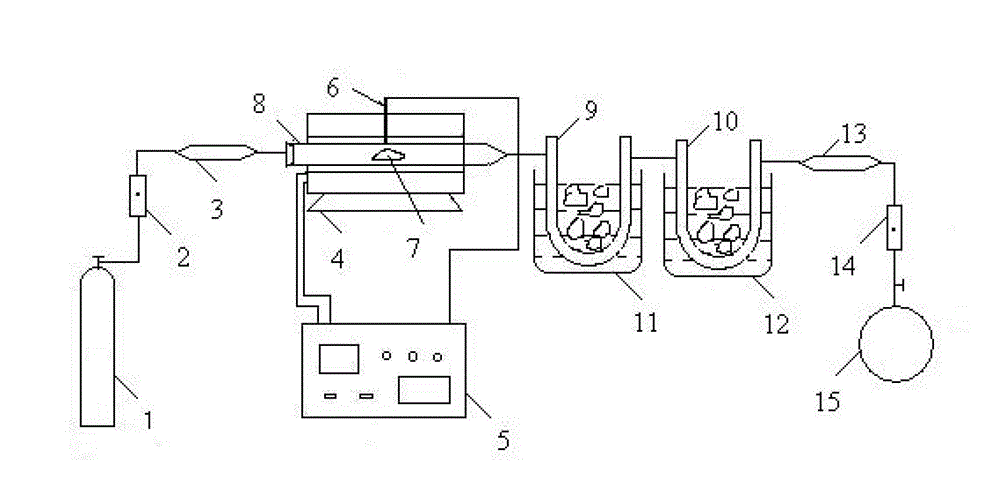

Image

Examples

Embodiment 1

[0032] Using fresh corn stalks as raw material, the raw material has a water content of 20.08% by mass percentage, crushing the fresh corn stalks into pellets below 2 mm, and adopting steps 1 to 4 of the method of the present invention to prepare hydrogen, and microwave pyrolysis in step 4 After 15 minutes of gasification, the gas products were collected, and the gas produced per kilogram of dry corn stalks was 0.66 kg, and the volume ratio of hydrogen was 60.2%.

Embodiment 2

[0034] Using fresh wheat stalks as raw materials, the moisture content of the raw materials is 30.01% by mass, and the same process as in Example 1 is adopted to produce 0.77 kg of gas per kilogram of dry corn stalks, of which the volume ratio of hydrogen is 63.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com