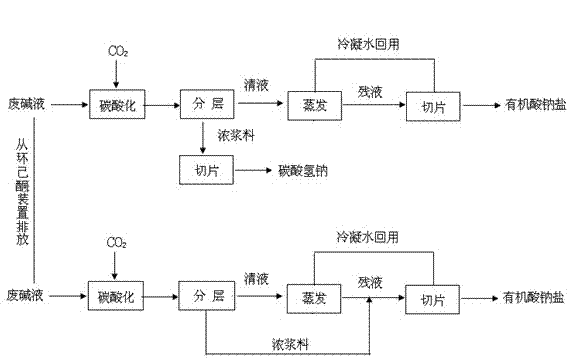

Method for recovering sodium bicarbonate and organic acid sodium salt from cyclohexanone waste alkali solution

A technology of organic sodium salt and sodium bicarbonate, applied in bicarbonate preparation, carboxylate preparation and other directions, can solve the problems of cumbersome process flow, difficult separation of solid and liquid, high processing energy consumption, and achieves short process flow and additional The effect of high value and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment one: extract crude product sodium bicarbonate, crude product organic acid sodium salt from waste lye.

[0026] From the cyclohexanone device, take volume and be 810ml of waste lye 1Kg, in 5000ml three-necked flask, waste lye and carbon dioxide gas generation carbonation reaction, record the pH value of reaction solution when being 8.3, stop reaction; The reaction solution was precipitated and layered. After a period of time, solid-liquid two-phase appeared in the flask, the upper layer was clear liquid, and the lower layer was thick slurry; put 500ml of supernatant into a 1000ml three-necked flask by siphon method, and open Water ring vacuum pump, keep the vacuum pressure in the three-neck flask at 60Kpa, collect condensed water, stop evaporation when the volume of condensed water reaches 250ml; put the evaporated residue into a crucible, heat it to 110°C in a muffle furnace, 380 g of crude organic acid sodium salt were obtained; the thick slurry was then pla...

Embodiment 2

[0027] Embodiment 2: extract crude product organic acid sodium salt from waste lye.

[0028] From the cyclohexanone device, get volume and be 810ml waste lye 1Kg, in 5000ml three-neck flask, waste lye and carbon dioxide gas generation carbonation reaction, record the pH value of reaction solution when being 8.5, stop reaction; The reaction solution was precipitated and layered. After a period of time, solid-liquid two-phase appeared in the flask, the upper layer was clear liquid, and the lower layer was thick slurry; put 500ml of supernatant into a 1000ml three-necked flask by siphon method, and open Water ring vacuum pump, keep the vacuum pressure in the three-necked flask at 60Kpa, collect condensed water, stop evaporation when the volume of condensed water reaches 250ml, put the evaporated residue into a 5000ml three-necked flask with thick slurry, and stir After mixing evenly, put it into a crucible and heat to 110° C. in a muffle furnace to obtain 550 g of crude organic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com