Annular Mg-Al double-hydroxy composite metal hydroxide and preparation method thereof

A double hydroxyl compound and hydroxide technology, applied in the direction of alumina/aluminum hydroxide, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of product purity impact, product target morphology collapse, etc. To achieve the effect of controllable shape, environment-friendly and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) MgCl 2 ·6H 2 O was dissolved in deionized water to prepare 20 ml of 4mol / L solution. Add MgO / MgCl in a constant temperature oil bath at 70°C 2 ·6H 2 O molar ratio is the MgO powder of 0.1, after stirring for 0.5 hours, stand at room temperature for 24 hours, put the obtained colloid into a volume of 50 milliliters of reaction kettle, 160 ° C in an oven, react for 6 hours, the product is washed with deionized water, and placed at room temperature Dried to Mg 10 (OH) 18 Cl 2 ·5H 2 O nanowires.

[0026] (2) 1.25 mmol AlCl 3 ·6H 2O and 6.75 millimoles of urea are dissolved in the mixed solvent of 25 milliliters of water and n-dodecanethiol to prepare the reaction solution, stir and ultrasonically dissolve all the reactants; the concentration of aluminum ion in the mixed solvent in the reaction solution is 0.05mol / L; the concentration of urea is 0.27mol / L; the volume ratio of organic solvent and water in the mixed solvent is 4:1.

[0027] (3) the Mg in the st...

Embodiment 2

[0030] (1) with embodiment one.

[0031] (2) 0.5 mmol Al 2 (SO 4 ) 3 18H 2 O and 2.7 millimoles of urea were dissolved in a mixed solvent of 50 milliliters of water and n-dodecyl alcohol to prepare a reaction solution, stirred and ultrasonicated until all the reactants were dissolved; the concentration of aluminum ions in the mixed solvent in the reaction solution was 0.01mol / L ; Urea concentration is 0.054mol / L; The volume ratio of organic solvent and water in the mixed solvent is 8:1.

[0032] (3) the Mg in the step (1) 10 (OH) 18 Cl 2 ·5H 2 O nanowire 0.106 gram is added in the above-mentioned reaction solution; Make the mol ratio of nanowire and Al salt be 0.3: 1, carry out solvothermal reaction in reactor, reaction temperature is 160 ℃, and reaction time is 4 hours, after reaction finishes, naturally Cool to room temperature; discharge, wash the obtained precipitate with water and ethanol, and dry to obtain MgAl-CO 3 Hydrotalcite nanorings.

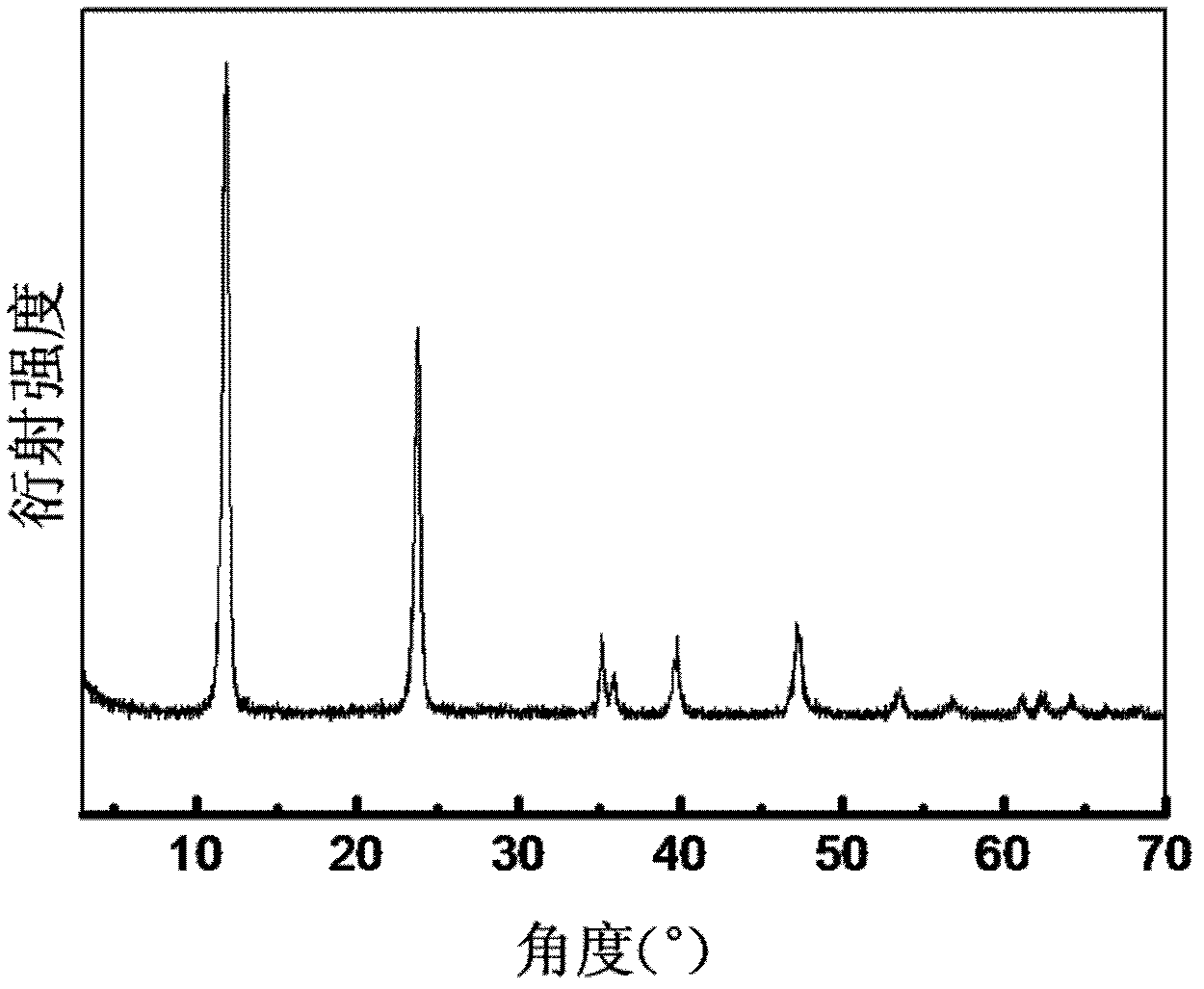

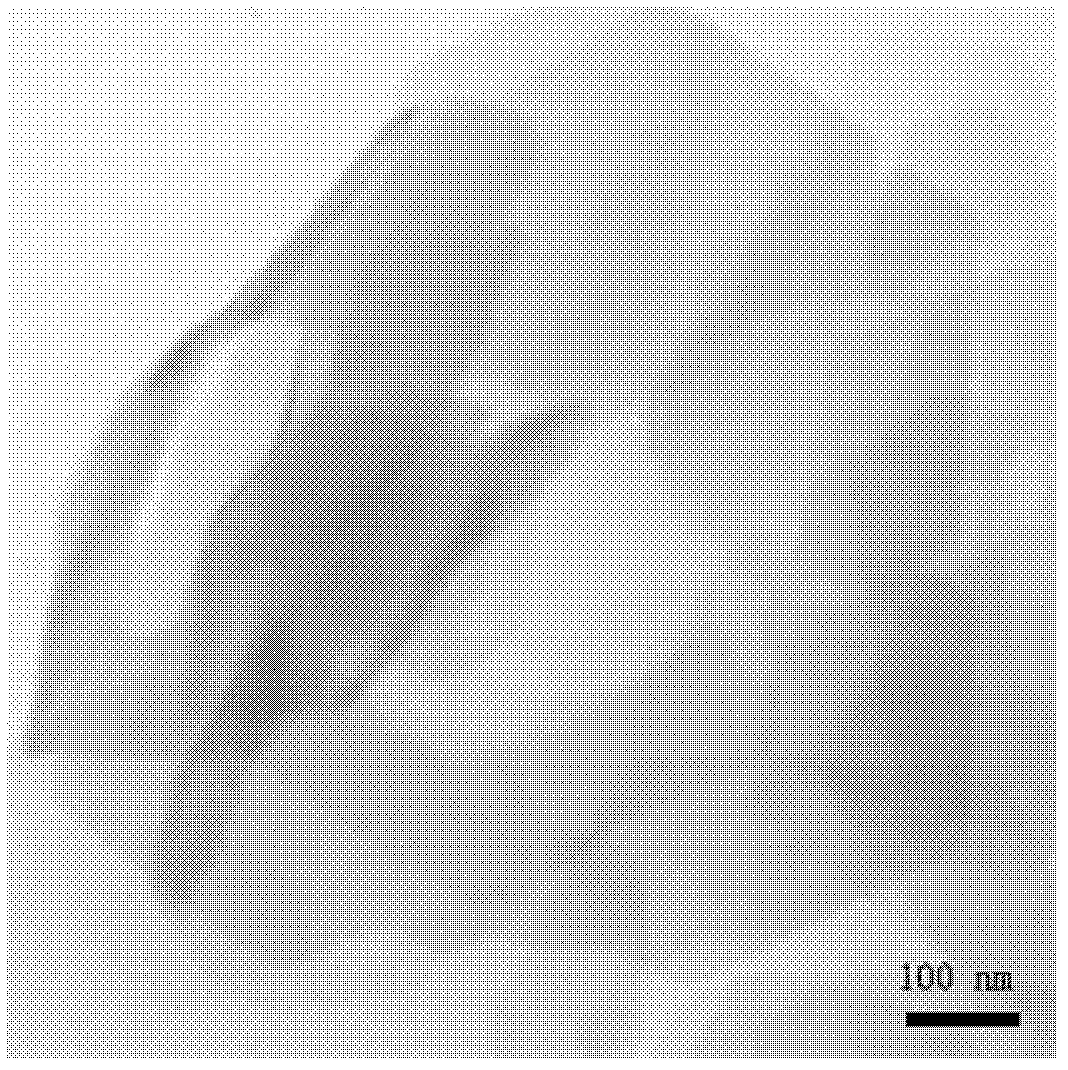

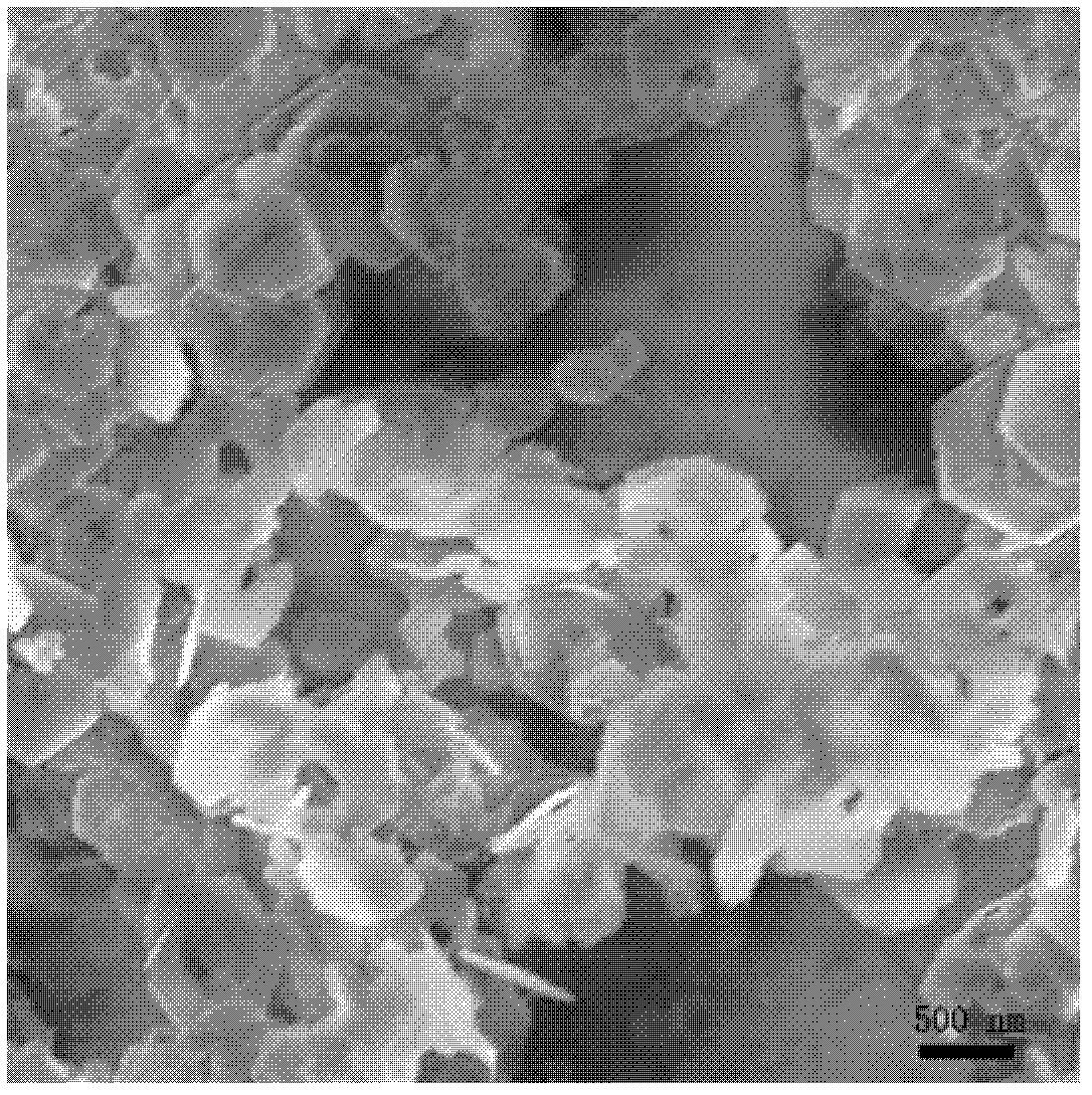

[0033] For characte...

Embodiment 3

[0035] (1) with embodiment one.

[0036] (2) 10 mmol Al(NO 3 ) 3 9H 2 O and 48 millimoles of urea were dissolved in the mixed solvent of 100 milliliters of water and n-hexanol to prepare the reaction solution, stirred and ultrasonicated until the reactant was completely dissolved; the concentration of aluminum ions in the mixed solvent in the reaction solution was 0.1mol / L; urea The concentration is 0.48mol / L; the volume ratio of organic solvent and water in the mixed solvent is 1:1.

[0037] (3) the Mg in the step (1) 10 (OH) 18 Cl 2 ·5H 2 1.414 grams of O nanowires are added in the above-mentioned reaction liquid; Make the mol ratio of nanowires and Al salt be 0.2: 1, carry out solvothermal reaction in reactor, reaction temperature is 100 ℃, and reaction time is 48 hours, after reaction finishes, naturally Cool to room temperature; discharge, wash the obtained precipitate with water and ethanol, and dry to obtain MgAl-CO 3 Hydrotalcite nanorings.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com