Preparation methods of diesel microemulsion and micro-emulsified diesel oil

A micro-emulsion and micro-emulsion technology, used in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve the problems of unfavorable storage and transportation, easy generation of gums, complicated preparation process, etc., and reduce carbon deposits and tail gas emissions. , improve the stability, the effect of simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of diesel microemulsion with water content of 10.4% and microemulsified diesel oil

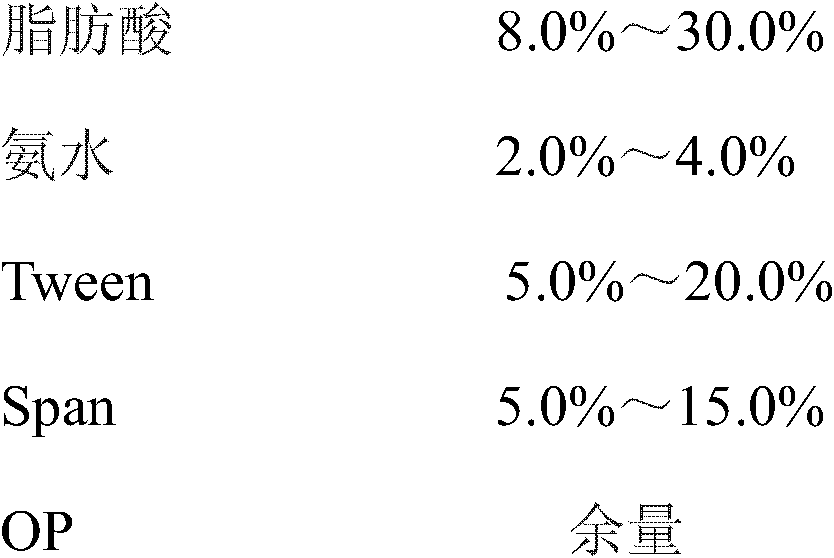

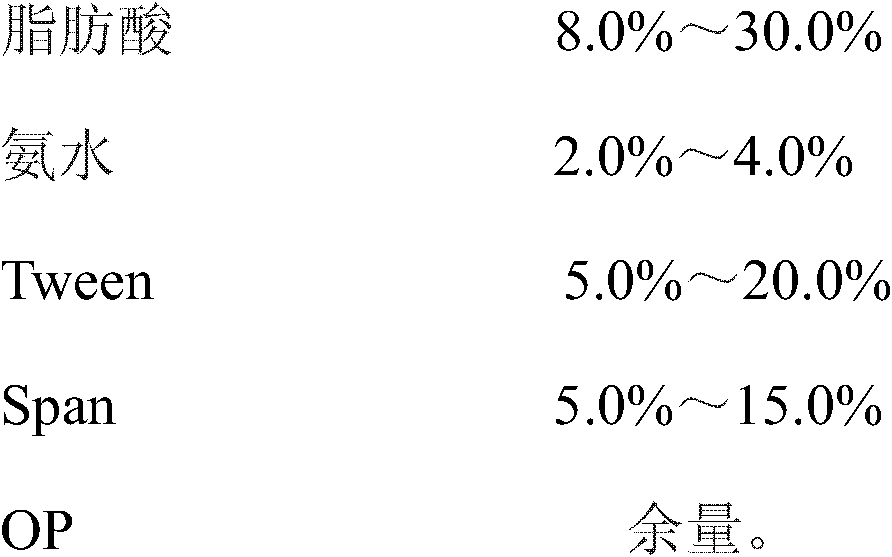

[0037] (1) Preparation of diesel microemulsion

[0038] In a 100ml Erlenmeyer flask, add 0.50 g of oleic acid, 00.6 g of ammonia, 800.39 g of Tween, 0.25 g of Span 80, and 1.3 g of OP-4 in sequence. Shake uniformly to completely dissolve the emulsifier.

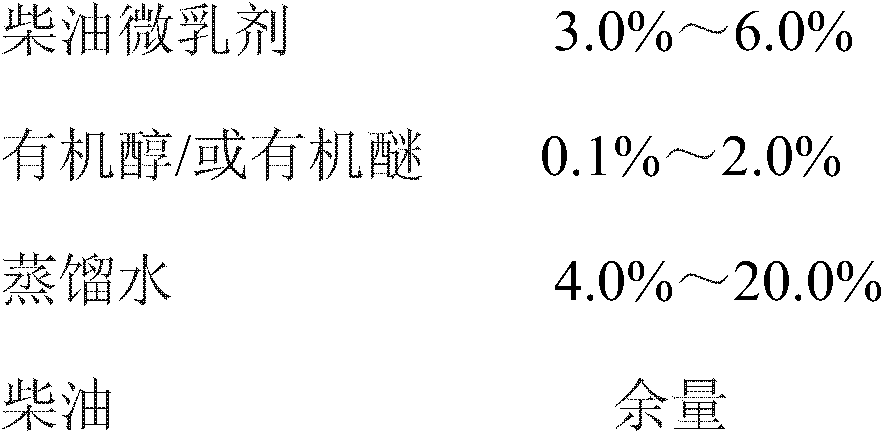

[0039] (2) Preparation of microemulsified diesel

[0040] At room temperature, weigh 42.5g of 0# diesel oil in a 100ml Erlenmeyer flask, then take 2.5g of the above diesel microemulsion and add it to the Erlenmeyer flask, shake it evenly, add 5.24g of water while shaking, and then add 0.13g of n-pentanol, if used In the oscillating mode, a translucent diesel microemulsion will be obtained after 7 hours; if ultrasonic dispersion is performed, the ultrasonic parameters are: 40KHz, 20min, 25°C, 127W, and the translucent microemulsified diesel can be obtained by standing for 10 minutes.

Embodiment 2

[0042] Preparation of diesel microemulsion with water content of 10.0% and microemulsified diesel oil

[0043] (1) Preparation of diesel microemulsion

[0044] In a 100ml Erlenmeyer flask, add 0.55 g of oleic acid, 0.06 g of ammonia, 850.16 g of Tween, 0.23 g of Span 20, and 1.27 g of OP-4 in sequence, and shake it evenly to completely dissolve the emulsifier.

[0045] (2) Preparation of microemulsified diesel

[0046] At room temperature, weigh 42.5g of 0# diesel oil in a 100ml Erlenmeyer flask, then add the above diesel oil microemulsion into the Erlenmeyer flask, shake evenly, add 5.00g water while shaking, then add 0.18g n-pentanol, shake evenly, and finally A translucent microemulsified diesel oil is obtained.

Embodiment 3

[0048] Preparation of diesel microemulsion with water content of 10.2% and microemulsion diesel oil

[0049] (1) Preparation of diesel microemulsion

[0050] In a 100ml Erlenmeyer flask, add 0.18 g of oleic acid, 0.02 g of ethanolamine, 0.18 g of Tween 85, 0.22 g of Span 83, and 1.64 g of OP-4 in sequence. Shake uniformly to completely dissolve the emulsifier.

[0051] (2) Preparation of microemulsified diesel

[0052] At room temperature, weigh 42.5g of 0# diesel oil in a 100ml Erlenmeyer flask, then add the above diesel microemulsion into the Erlenmeyer flask, shake evenly, add 5.08g water while shaking, then add 0.10g n-pentanol, shake evenly, and finally A translucent microemulsified diesel oil is obtained.

[0053] The microemulsion prepared by the invention does not contain metal ions, halogens, sulfur elements, and other substances that are unfavorable to equipment and the environment, and belongs to oxygen-containing compounds, which is helpful for the complete combustion of mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com