Analysis method of organic acid content in rubber steel wire adhesive organic acid cobalt salt

A technology of organic acid cobalt salt and analysis method, which is applied in the direction of analysis materials, measurement devices, material separation, etc., and can solve the problems that no literature and methods have been published in the analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

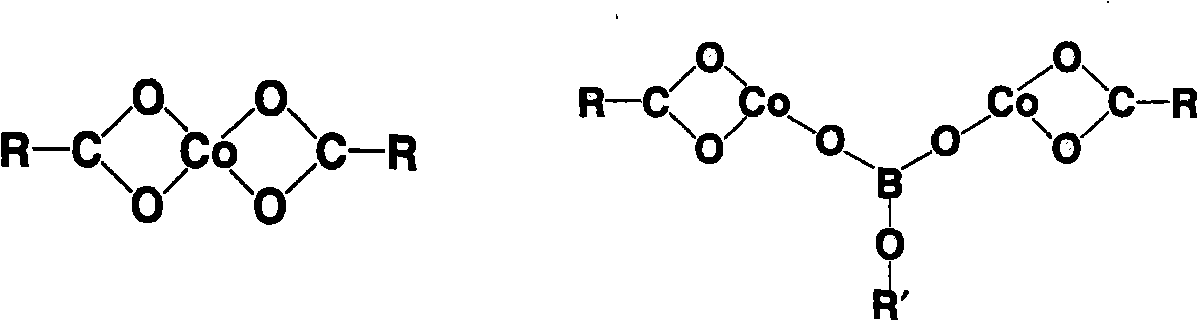

[0029] Embodiment 1: Quantitative analysis of organic acid in certain cobalt decanoate

[0030] 1. Quantitative analysis of organic acids with C2-C8 carbon atoms in cobalt decanoate

[0031] 1.1 Preparation of internal standard solution: Weigh 191.5mg of n-butyric acid into a 25ml volumetric flask, and dilute to volume with n-heptane.

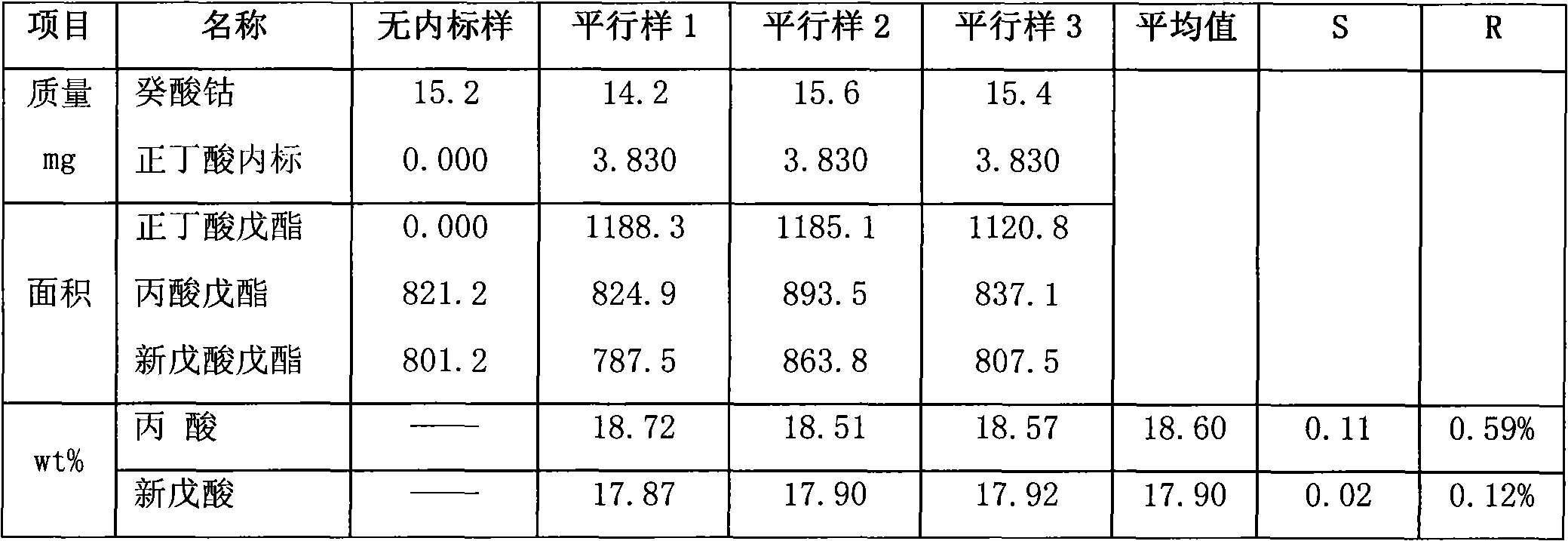

[0032] 1.2 Sample preparation: Grind cobalt decanoate fully, weigh 15.2mg (without internal standard sample), 14.2mg, 15.6mg, 15.4mg (parallel sample) powder samples into four 10ml volumetric flasks, and use a pipette gun to accurately Pipette 500μl of internal standard solution into three parallel samples, then add 2ml of boron trifluoride-n-pentanol solution, place in 85°C water bath for 1h, add 3mL of n-heptane and shake vigorously for at least 15s, continue to add 5mL Shake the saturated sodium chloride solution well, let it stand for stratification, and take the upper layer solution for gas chromatography analysis.

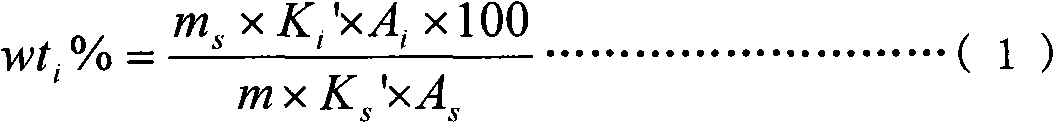

[0033] 1.3 Calculati...

Embodiment 2

[0052] Embodiment 2: Quantitative analysis of organic acid in certain cobalt stearate

[0053] 1. Quantitative analysis of organic acids with C8-C22 carbon atoms in cobalt stearate

[0054] 1.1 Preparation of internal standard solution: Weigh 103.8mg capric acid into a 25ml volumetric flask, and dilute to volume with n-heptane.

[0055] 1.2 Sample preparation: Grind cobalt stearate thoroughly, weigh 15.3mg (without internal standard sample), 17.3mg, 17.8mg, 15.0mg (parallel sample) powder samples into four 10ml volumetric flasks. Use a pipette gun to accurately pipette 500 μl of internal standard solution into three parallel samples. After adding 3mL of boron trifluoride-methanol solution, place it in a water bath at 75°C for 1h, then add 5mL of n-heptane to fully shake for extraction, continue to add 10ml of saturated sodium chloride solution, shake fully and let it stand for stratification. analyze.

[0056] 1.3 Calculation results are listed in the table below:

[0057]...

Embodiment 3

[0061] Embodiment 3: Quantitative analysis of organic acid in certain cobalt boroacylate

[0062] 1. Quantitative analysis of C2-C8 organic acids in cobalt boroacylate

[0063] 1.1 Preparation of internal standard solution: Weigh 70.4mg of n-butyric acid into a 25ml volumetric flask, and dilute to volume with n-heptane.

[0064] 1.2 Sample preparation: Grind cobalt boroacylate fully, weigh 16.2mg (without internal standard sample), 16.3mg, 17.3mg, 15.6mg (parallel sample) powder samples into four 10ml volumetric flasks, and use a pipette gun Accurately pipette 300μl of internal standard solution into three parallel samples, then add 2ml of boron trifluoride-n-pentanol solution, place it in a water bath at 85°C for 1h, add 3mL of n-heptane and shake vigorously for at least 15s, continue to add Shake 5mL saturated sodium chloride solution well, let it stand for stratification, and take the upper layer solution for gas chromatography analysis.

[0065] 1.3 Calculation of results ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com