Preparation method of blueberry instant powder

The technology of an instant powder and a preparation method is applied in the field of preparation of blueberry instant powder, can solve the problems such as insufficient development and utilization, and achieve the effects of multiple health care functions, rich nutrition and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

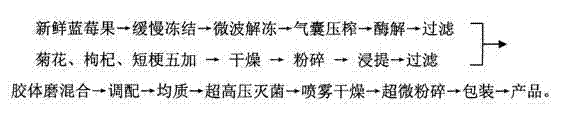

[0011] See figure 1 After picking fresh blueberries and removing moldy and rotten fruits, take 100kg of fresh fruits and put them directly into the still cold air at -10°C for slow freezing for 48 hours, then take 10Kg of blueberry frozen fruits and thaw them with microwave. The power of thawing is 200W, and the time When the temperature of the center of the frozen blueberries reaches 0°C, the thawing is over. Put the thawed blueberries into a vacuum air bag press and squeeze them under a pressure of 0.7 bar. After activating for 0.5h, the enzyme activity is 50U / g of pectinase. After 1h of enzymolysis, filter with 400 mesh double-layer filter cloth to get the juice for later use.

[0012] Then weigh 25g of chrysanthemum, 35g of Chinese wolfberry, and 40g of dry products of Wujia Wujia, crush and mix them evenly, pass through a 100-mesh sieve, add 3Kg of hot water at a temperature of 80°C, and extract for 3 hours. Get 2.5Kg extract and 2.5Kg standby blueberry juice after singl...

Embodiment 2

[0014] See figure 1 After picking fresh blueberries and removing moldy and rotten fruits, take 100kg of fresh fruits and put them directly into the still cold air at -15°C for slow thawing for 36 hours, then take 10Kg of blueberry frozen fruits and thaw them with microwaves. When the temperature of the center of the frozen blueberries reaches 0.5°C, the thawing is over. Put the thawed blueberries into a vacuum air bag press and squeeze them under a pressure of 0.8 bar. After activation for 0.75 h, the enzyme activity is 50 U / g of pectinase. After 1.25 h of enzymolysis, filter with 400-mesh double-layer filter cloth to get the juice for later use.

[0015] Then weigh 25g of chrysanthemum, 35g of Chinese wolfberry, and 40g of dry products of Wujia Wujia, crush and mix them evenly, pass through a 100-mesh sieve, add 3Kg of hot water at a temperature of 80°C, and extract for 3 hours. After filtering with a single-layer filter cloth, take 2.5Kg extract and 2.5Kg standby blueberry ...

Embodiment 3

[0017] See figure 1 After picking fresh blueberries and removing moldy and rotten fruits, take 100kg of fresh fruits and put them directly into the still cold air at -20°C for slow freezing for 24 hours, then take 10Kg of blueberry frozen fruits and thaw them with microwaves. When the temperature of the center of the frozen blueberry fruit reaches 1°C, the thawing is over. Put the thawed blueberry fruit into a vacuum air bag press, squeeze it under a pressure of 0.9 bar, add 8.0g of blueberry fruit and put it under the condition of a constant temperature water bath at 50°C. Pectinase with an enzyme activity of 50 U / g after activation for 1 h, and after 1.5 h of enzymolysis, filter with a 400-mesh double-layer filter cloth to get the juice for later use.

[0018] Then weigh 25g of chrysanthemum, 35g of Chinese wolfberry, and 40g of dry products of Wujia Wujia, crush and mix them evenly, pass through a 100-mesh sieve, add 3Kg of hot water at a temperature of 80°C, and extract fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com