Method for peeling off hexagonal lamellar boron nitride and doping fluorine in hexagonal lamellar boron nitride

A boron nitride and fluorine doping technology, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve problems such as polluted environment and complex preparation methods, and achieve simple preparation methods, abundant raw materials, and easy mass production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

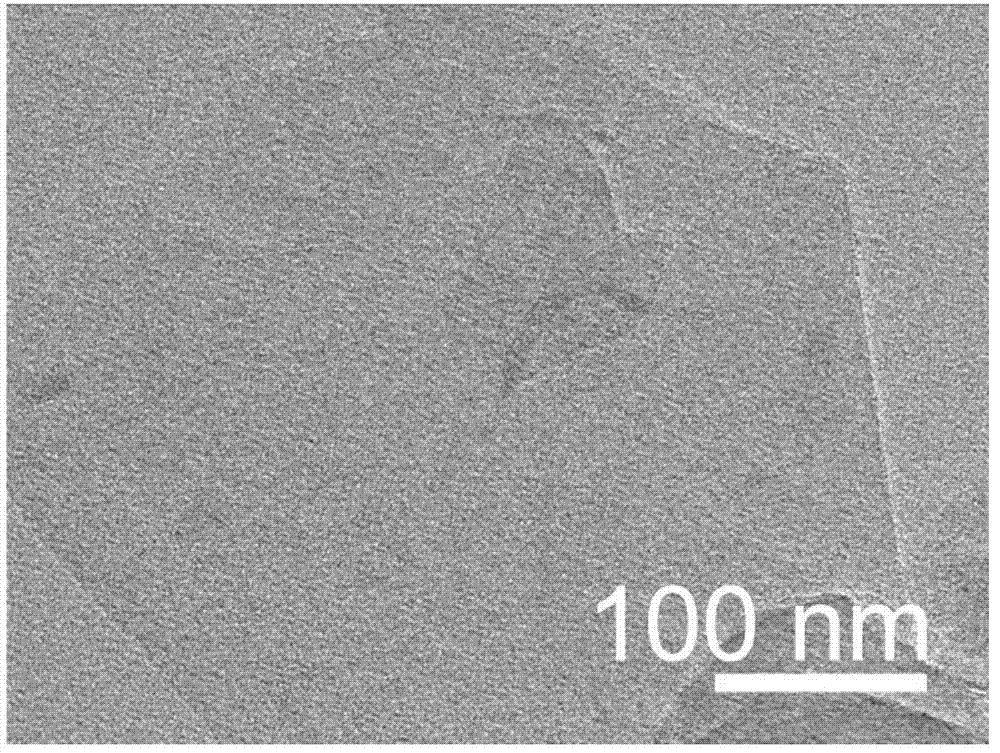

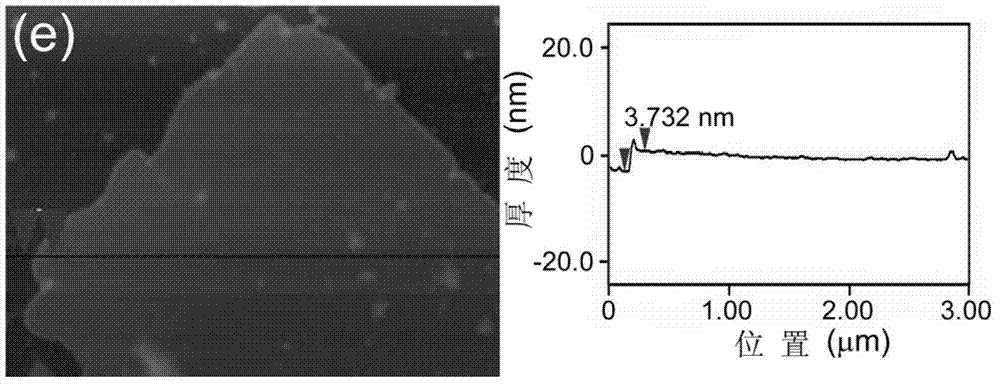

[0027] (1) Preparation of single-layer or few-layer hexagonal layered boron nitride by exfoliation with isopropanol: put 0.5 g of bulk boron nitride powder into a 100 mL round-bottomed flask, and add 50 mL of isopropanol. The above mixture was magnetically stirred at 50 °C for 24 h. After cooling to room temperature, the above mixture was sonicated in a low-power ultrasonic machine for 20 h. After the sonication, the obtained mixture was left to stand at room temperature for 1 day, and then the supernatant was extracted and centrifuged, and the centrifuged milky white precipitate was washed several times with acetone to clean the isopropanol. The obtained product was dried at 60°C and collected for future use.

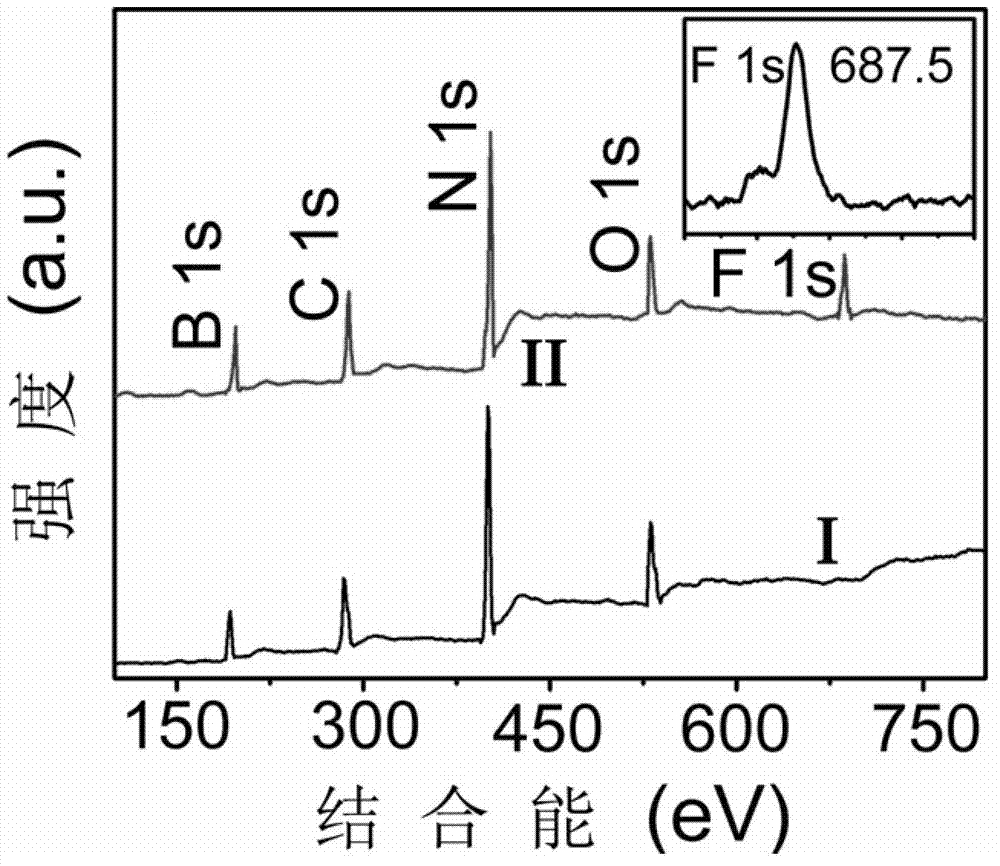

[0028] (2) Few-layer or single-layer hexagonal boron nitride doped with fluorine: put 0.5g of few-layer hexagonal boron nitride into a 100mL round bottom flask, add 50mL of fluoroboric acid (HBF 4 ), the above-mentioned mixed solution was magnetically stirred at 50° ...

Embodiment 2

[0030] (1) Preparation of monolayer or few-layer hexagonal layered boron nitride by exfoliation with dimethyl sulfoxide: put 0.5 g of bulk boron nitride powder into a 100 mL round bottom flask, and add 50 mL of dimethyl sulfoxide. The above mixture was magnetically stirred at 50 °C for 24 h. After cooling to room temperature, the above mixture was sonicated in a low-power ultrasonic machine for 20 h. After the sonication, the resulting mixture was left to stand at room temperature for 2 days, then the supernatant was extracted and centrifuged, and the centrifuged milky white precipitate was washed several times with acetone to clean the isopropanol. The obtained product was dried at 60°C and collected for future use.

[0031] (2) Few-layer or single-layer hexagonal boron nitride doped with fluorine: put 0.5g of few-layer hexagonal boron nitride into a 100mL round bottom flask, add 50mL of fluoroboric acid (HBF 4 ), the above-mentioned mixed solution was magnetically stirred ...

Embodiment 3

[0033] (1) Preparation of monolayer or few-layer hexagonal layered boron nitride by exfoliation with N-methylpyrrolidone: put 0.2 g of bulk boron nitride powder into a 100 mL round-bottomed flask, and add 30 mL of N-methylpyrrolidone. The above mixture was magnetically stirred at 50 °C for 24 h. After cooling to room temperature, the above mixture was sonicated in a low-power ultrasonic machine for 20 h. After the sonication, the resulting mixture was left standing at room temperature for 3 days, then the supernatant was extracted and centrifuged, and the centrifuged milky white precipitate was washed several times with acetone to clean the isopropanol. The obtained product was dried at 60°C and collected for future use.

[0034] (2) Few-layer or single-layer hexagonal boron nitride doped with fluorine: put 0.2g of few-layer hexagonal boron nitride into a 100mL round bottom flask, add 30mL of fluoroboric acid (HBF 4 ), the above-mentioned mixed solution was magnetically stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com