Preparation method of high salinity heavy oil sewage deoiling water purifier

A technology of heavy oil sewage and high salinity, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of slow settling or floating speed, incomplete flocculation, salting out phenomenon, etc., and achieve good oil removal and water purification effect. , The effect of fast precipitation and low moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

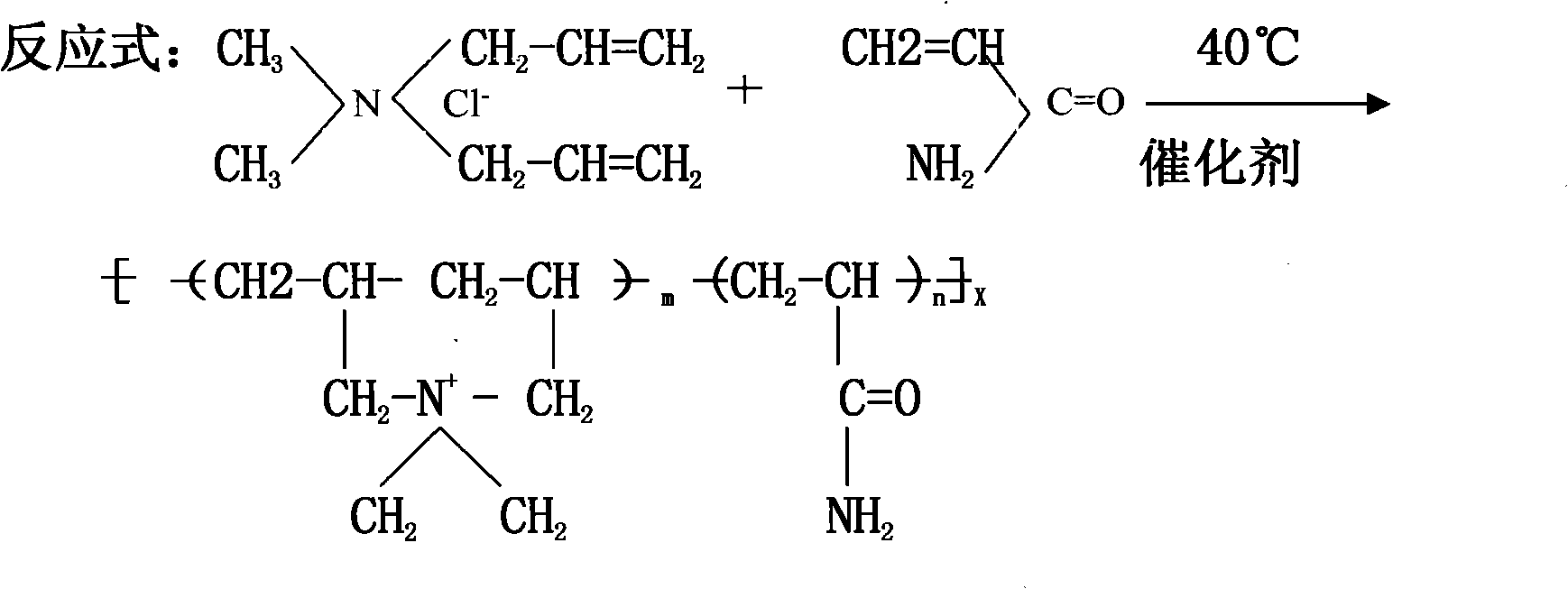

Method used

Image

Examples

Embodiment 1

[0025] Add 323.34kg dimethyldienylpropyl ammonium chloride and 710kg acrylamide to the reaction kettle, add 1550kg water to dilute to a weight concentration of 40%, control the temperature at 20-30°C, and adjust the pH range to 2.5 with hydrochloric acid -3.5, feed nitrogen protection, react at a constant temperature of 40°C for 30 minutes, add 0.52kg of initiator potassium persulfate-sodium bisulfite in a weight ratio of 2:1 mixture, and polymerize under nitrogen protection at 40°C 8- After 10 hours, the cationic polymer flocculant product, numbered as 1# flocculant, was obtained.

[0026] Add 30 kg of stearyl alcohol to the reaction kettle, 1.5 kg of potassium hydroxide catalyst to control the temperature at 110 to 120 ° C to control the pressure of the kettle to 0.2 to 0.3 MPa, pressurize nitrogen into 600 kg of ethylene oxide and propylene oxide for polymerization reaction to obtain oil head. Put 42kg of synthetic oil head into the reaction kettle, heat to 134-150°C, add 2...

Embodiment 2

[0029] Add 323.34kg of dimethyldienylpropyl ammonium chloride and 640kg of acrylamide to the reaction kettle, add 1529kg of water to dilute to a weight concentration of 40%, control the temperature at 20-30°C, and adjust the pH range to 2.5 with hydrochloric acid -3.5, feed nitrogen protection, react at a constant temperature of 40°C for 30 minutes, add 0.385kg of initiator potassium persulfate-sodium bisulfite in a weight ratio of 2:1 mixture, and polymerize under nitrogen protection at 40°C 8- After 10 hours, the cationic polymer flocculant product, numbered as 1# flocculant, was obtained.

[0030] Add 20kg of propylene glycol to the autoclave, control the temperature of 1.5kg of potassium hydroxide catalyst at 110-120°C to control the pressure of the autoclave to 0.2-0.3MPa, inject 500kg of propylene oxide into the autoclave for polymerization reaction to obtain oil head. Take 52kg of synthetic oil head and put it into the reaction kettle, heat it to 134-150°C, add 2.5kg of...

Embodiment 3

[0033] Add 323.34kg dimethyldienylpropyl ammonium chloride and 568.4kg acrylamide to the reaction kettle, add 1337.6kg water to dilute to a weight concentration of 40%, control the temperature at 20-30°C, and adjust the pH range with hydrochloric acid At 2.5-3.5, pass nitrogen protection, and after reacting at a constant temperature of 40°C for 30 minutes, add 0.267kg of initiator potassium persulfate-sodium bisulfite in a weight ratio of 2:1 mixture, and polymerize under the protection of nitrogen at 40°C After 8-10 hours, the cationic polymer flocculant product, numbered 3# flocculant, is obtained.

[0034] Add 20kg of propylene glycol into the reaction kettle, 1.5kg of potassium hydroxide catalyst and control the temperature at 110 to 120°C to control the pressure of the kettle to 0.2 to 0.3MPa, inject 500kg of propylene oxide into the reaction kettle for polymerization reaction to obtain oil head. Take 52kg of synthetic oil head and put it into the reaction kettle, heat it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com