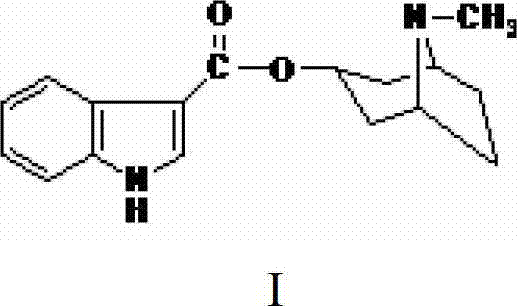

Preparation method of tropisetron

A technology of tropisetron and tropinol, which is applied in the field of preparation of antiemetic drug tropisetron, can solve the problems of reduced purity, high reaction temperature, and increased impurities, so as to reduce costs, operational risks, and mild reaction conditions , the effect of high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

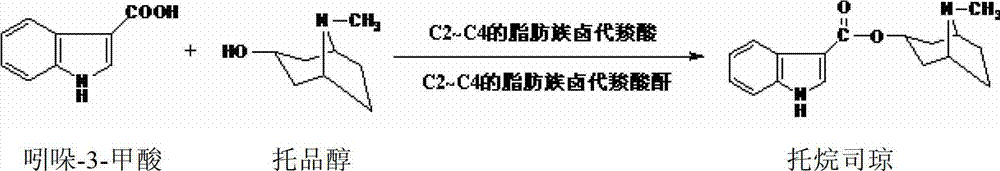

[0009] A preparation method for tropisetron, the method comprising: in an inert solvent, using a C2-C4 aliphatic halogenated carboxylic acid as a catalyst, a C2-C4 aliphatic halogenated carboxylic acid anhydride as an activating reagent, and indole -3-Formic acid is activated as a mixed acid anhydride, and then a solution of tropine alcohol dissolved in an inert solvent is added dropwise to carry out a condensation reaction to prepare tropisetron; the indole-3-formic acid: C2~C4 aliphatic halogenated Carboxylic anhydride: C2~C4 aliphatic halogenated carboxylic acid: tropinol, the material molar ratio is 1:0.5~2:0.1~3:0.5~5.

[0010] Preferably, a kind of preparation method of tropisetron comprises the following steps:

[0011] (1) Add inert solvent and catalyst C2~C4 aliphatic halogenated carboxylic acid to indole-3-carboxylic acid, add activating reagent C2~C4 aliphatic halogenated carboxylic acid anhydride under stirring, activate at -10~40°C for 0.5 ~10h; After the activat...

Embodiment 1

[0038] Add 200ml of dichloromethane and 1.4g of trifluoroacetic acid to 20g of indole-3-carboxylic acid, add 50g of trichloroacetic anhydride under stirring, and activate at 20°C for 2h. After the activation was completed, the temperature was lowered to -5°C, and 50 ml of dichloromethane solution containing 17.6 g of tropinol was added dropwise. After the dropwise addition, the reaction solution was clear and reacted for 1 h. After the reaction is complete, wash twice with 100ml of 1mol / L NaOH aqueous solution and 100ml of purified water each time, add 50g of sodium sulfate to dry for 2h, filter with suction, evaporate the filtrate to dryness, add 50ml of ethyl acetate to make a slurry, cool down at 0-5°C and analyze crystallization, suction filtration, and drying to obtain 28.3 g of tropisetron, with a yield of 80.2% and a purity of 99.4%.

Embodiment 2

[0040]Add 125ml of chloroform and 12.7g of trichloroacetic acid to 25g of indole-3-carboxylic acid, add 51g of heptafluorobutyric anhydride under stirring, and activate at 40°C for 0.5h. After the activation was completed, the temperature was lowered to -10°C, and 100 ml of a chloroform solution containing 22 g of tropinol was added dropwise. After the dropwise addition, the reaction solution was clear and reacted for 4 hours. After the reaction is complete, wash twice with 125ml of 1mol / L NaOH aqueous solution and 125ml of purified water each time, add 50g of sodium sulfate to dry for 2h, filter with suction, evaporate the filtrate to dryness, add 50ml of ethyl acetate for beating, 0-5°C Cooling and crystallization, suction filtration, and drying gave 36 g of tropisetron with a yield of 82% and a purity of 99.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com