Cracking and hollowing resistant aerated concrete water repellent and use method thereof

A technology of air-entrained concrete and water-repellent, applied in the field of building materials, can solve problems such as imperfect construction technology and quality control measures, late development and application of air-entrained concrete, and lack of in-depth and meticulous air-entrained concrete blocks, etc., to achieve Reduce hollowing and cracking, reduce swelling and shrinkage, and reduce water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

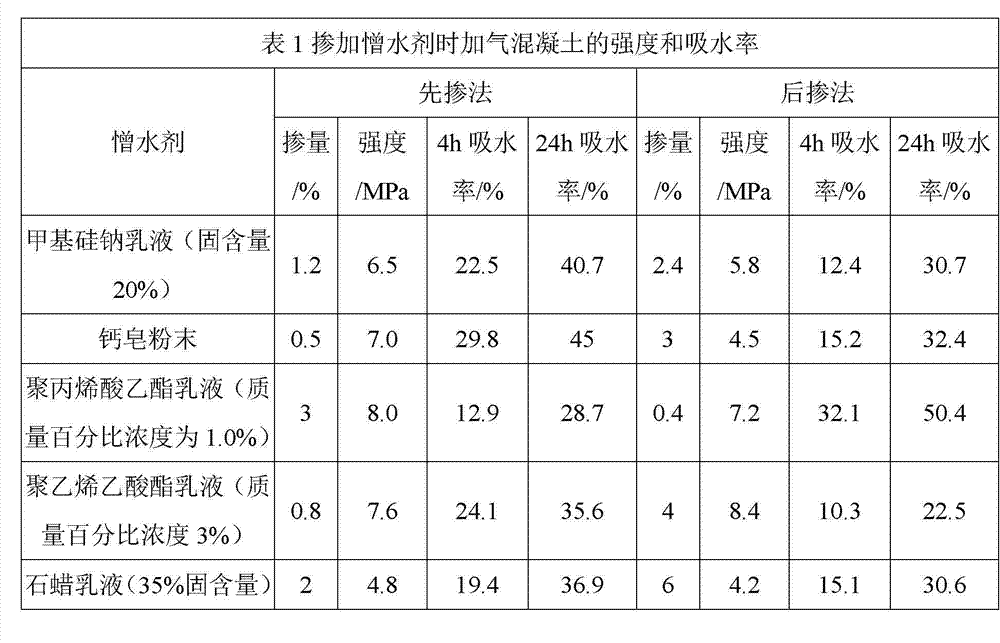

Image

Examples

Embodiment 1

[0025] The raw materials and ratio (mass ratio) of an air-entrained concrete are: Class II fly ash: Class 42.5 P.O cement: lime: phosphogypsum: aluminum foaming agent (aluminum powder): foam stabilizer (chemical composition is twelve Alkyl dimethyl amine oxide) = 76.4: 4.7: 16.5: 2.4: 0.05: 0.021, the ratio of water to material is 0.5. After mixing the above raw materials, mix them with a concrete mixer for 5 minutes; 3 In the test mold (the pouring amount is about 1 / 3 of the height of the test mold) and stop at room temperature and pressure for 5-6 hours. The concrete test mold is placed in a steam curing room (curing temperature is 190°C, steam pressure is 1.9MPa) for 10 hours; finally, the air-entrained concrete is demoulded and placed in a standard curing room (temperature is 20°C, humidity is 90%) Conservation 7d. The compressive strength of the air-entrained concrete was measured to be 7.5MPa, and the water absorption rates after immersion in water for 4 hours and 24 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com