Method for preparing 2-chlorine-3-amino-4-picoline

A technology of picoline and amino, which is applied in the field of preparing 2-chloro-3-amino-4-picoline, can solve the problems of cumbersome steps, high cost, high equipment requirements, etc., and achieve mild reaction conditions, reasonable price, and raw materials Easy to get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

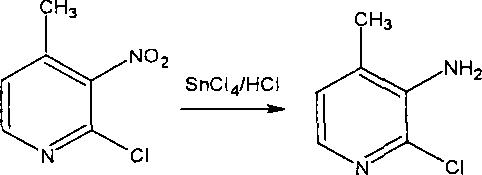

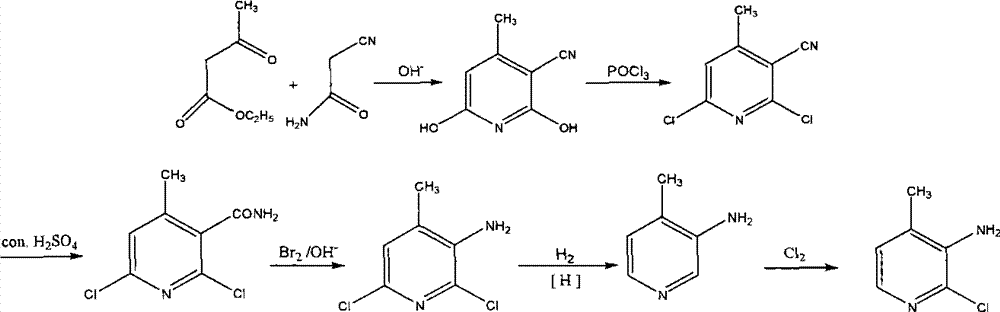

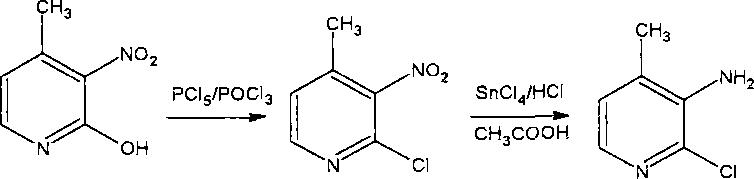

Method used

Image

Examples

Embodiment 1

[0041] (1) Preparation of N-nitro-4-picoline: First add 200mL trifluoroacetic anhydride (0.84mol) to the reaction kettle, stir and cool to 0°C, slowly add 33mL 4-picoline (0.34mol) dropwise , A yellow solid was produced. After the addition was complete, the stirring reaction was continued at 0° C. for 2 h. Afterwards, 38 mL of concentrated nitric acid (0.72 mol) was added dropwise, the reaction temperature was gradually raised to room temperature, and the reaction was continued to stir for 10 h to obtain a solution of N-nitro-4-picoline, which was directly entered into the next step without further treatment.

[0042] (2) Preparation of 3-nitro-4-picoline: Add the N-nitro-4-picoline reaction solution obtained in the previous step dropwise to 64g of frozen sodium pyrosulfate (0.34mol) and 500mL of aqueous solution , stirred at room temperature for 24h, adjusted the pH of the system with 25% NaOH aqueous solution=6-7, CH 2 Cl 2 The product was extracted, the extract was dried,...

Embodiment 2

[0046] Synthesize as the method and condition of embodiment 1, (1), (3), (4) step reaction is unchanged, only change sodium pyrosulfate into sodium sulfite in (2) step, obtain product 3-nitro-4-formazine The crude product of pyridine has a purity of 75.4% and a yield of 60.3%.

Embodiment 3

[0048] Synthesize as the method and condition of embodiment 1, (1), (3), (4) step reaction is unchanged, only change sodium pyrosulfate into sodium bisulfite in (2) step, obtain product 3-nitro- The crude product of 4-picoline has a purity of 79.2% and a yield of 62.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com