Process for preparing epoxypropane by directly using epoxidation propylene through hydrogen peroxide

A technology for epoxidizing propylene and propylene oxide, which is applied in the chemical industry, sustainable manufacturing/processing, organic chemistry, etc., can solve the problems of environmental protection and energy saving at the same time, and achieve significant economic and social benefits and energy consumption. The effect of improving safety and improving conversions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

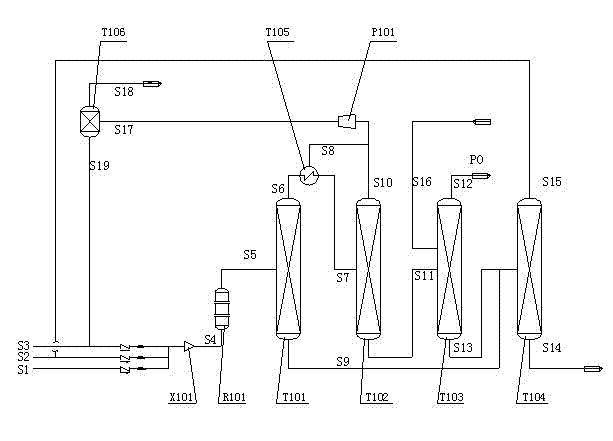

[0032] (1) if figure 1 As shown, after fresh propylene, recycled propylene, hydrogen peroxide with a mass concentration of 27.5-60% and circulating solvent are mixed by X101 mixer, the epoxidation reaction is carried out on titanium-silicon molecular sieve fixed-bed reactor R101. The reaction pressure is 10-30 bar, the temperature is 30-80° C., and the reaction solvent can be methanol, acetone or other mixture solvents.

[0033] (2) The reaction product passes through the propylene oxide crude separation tower T101, and the kettle liquid is treated with alkali substances, and then enters the solvent recovery tower T104; the pressure at the top of the crude separation tower is 10-20bar, and the temperature at the top of the tower is controlled at 30-60°C. The temperature is controlled at 60-100°C.

[0034] (3) The crude propylene oxide product is separated from unreacted propylene in the propylene flash tower T105. The top pressure of the propylene flash tower is 2-10 bar, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com