Sludge synthetic fuel and method for preparing same

A technology for synthesizing fuel and sludge, applied in the direction of fuel, solid fuel, biofuel, etc., can solve the problems of high sludge treatment difficulty, small sludge utilization, single practicability, etc., and achieve simplified equipment and sludge utilization rate. The effect of high and high equipment safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

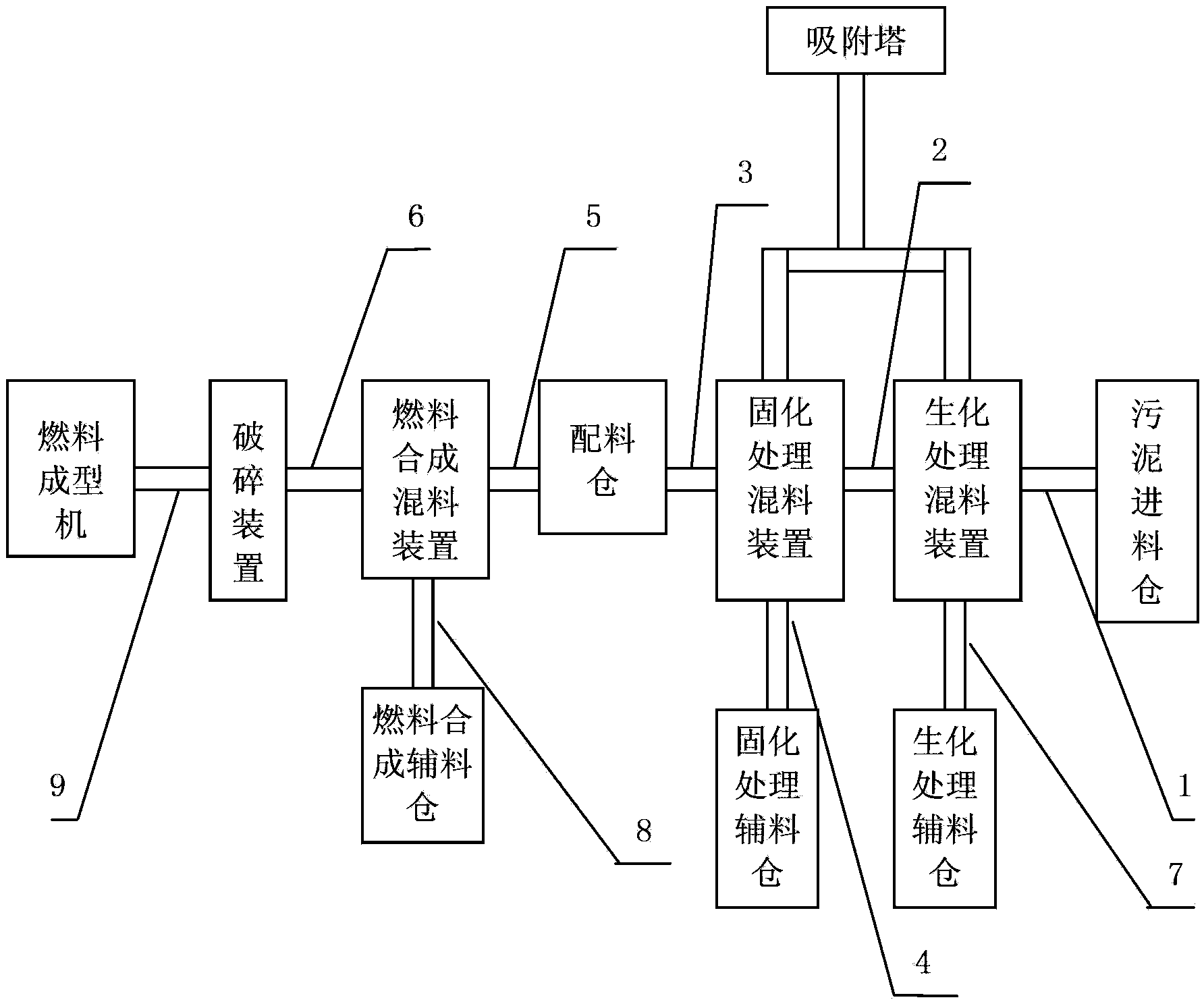

[0034] A preparation method of sludge synthetic fuel, realized by a preparation system of sludge synthetic fuel, comprising the following steps:

[0035] 1) Pour the sludge with a weight percentage of 40% into the sludge feeding bin, and add the sludge to the biochemical treatment mixing device through the sludge conveying device 1; The treatment auxiliary material delivery device 7 adds the biochemical treatment auxiliary material to the biochemical treatment mixing device, and the biochemical treatment mixing device performs mixing and biochemical treatment on the sludge and the biochemical treatment auxiliary material to deodorize and sterilize the sludge;

[0036] 2) After the sludge is biochemically treated, it enters the solidification treatment mixing device through the biochemical treatment mixing conveying device 2, and at the same time, the solidification treatment auxiliary material is added to the solidification treatment auxiliary material bin, and then the solidif...

Embodiment 2

[0040] A preparation method of sludge synthetic fuel, realized by a preparation system of sludge synthetic fuel, comprising the following steps:

[0041] 1) Pour the sludge with a weight percentage of 40% into the sludge feeding bin, and add the sludge to the biochemical treatment mixing device through the sludge conveying device 1; The treatment auxiliary material delivery device 7 adds the biochemical treatment auxiliary material to the biochemical treatment mixing device, and the biochemical treatment mixing device performs mixing and biochemical treatment on the sludge and the biochemical treatment auxiliary material to deodorize and sterilize the sludge;

[0042] 2) After the sludge is biochemically treated, it enters the solidification treatment mixing device through the biochemical treatment mixing conveying device 2, and at the same time, the solidification treatment auxiliary material is added to the solidification treatment auxiliary material bin, and then the solidif...

Embodiment 3

[0046] A preparation method of sludge synthetic fuel, realized by a preparation system of sludge synthetic fuel, comprising the following steps:

[0047] 1) Pour the sludge with a weight percentage of 40% into the sludge feeding bin, and add the sludge to the biochemical treatment mixing device through the sludge conveying device 1; The treatment auxiliary material delivery device 7 adds the biochemical treatment auxiliary material to the biochemical treatment mixing device, and the biochemical treatment mixing device performs mixing and biochemical treatment on the sludge and the biochemical treatment auxiliary material to deodorize and sterilize the sludge;

[0048] 2) After the sludge is biochemically treated, it enters the solidification treatment mixing device through the biochemical treatment mixing conveying device 2, and at the same time, the solidification treatment auxiliary material is added to the solidification treatment auxiliary material bin, and then the solidif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com