Preparation method of protein-grain-supported-in-beaded-fiber tissue engineering fiber support frame

A protein particle and tissue engineering technology, applied in medical science, prosthesis, etc., can solve the problems of unable to optimize the protein release curve, unable to overcome the problem of protein drug burst release, etc., to improve the in vitro release curve, low cost and simple method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of A solution: Dissolve polylactic acid-glycolic acid copolymer in a mixed solvent of 0.25 mL N,N-dimethylformamide and 0.75 mL tetrahydrofuran to obtain A solution with a concentration of 150 mg / mL.

[0030] (2) Preparation of solution B: add 15 mg of dextran particles loaded with bovine serum albumin with a particle size of 227-1575 nm to solution A, and stir with magnetic force at 2000 rpm for 60 min.

[0031] (3) Electrospinning: Add B solution into the syringe, set the spinning voltage to 20kV, the spinning speed to 1mL / h, and the spinning distance to 20cm, and perform electrospinning on the receiver (a metal plate covered with a layer of aluminum foil). Collect the fibrous membrane.

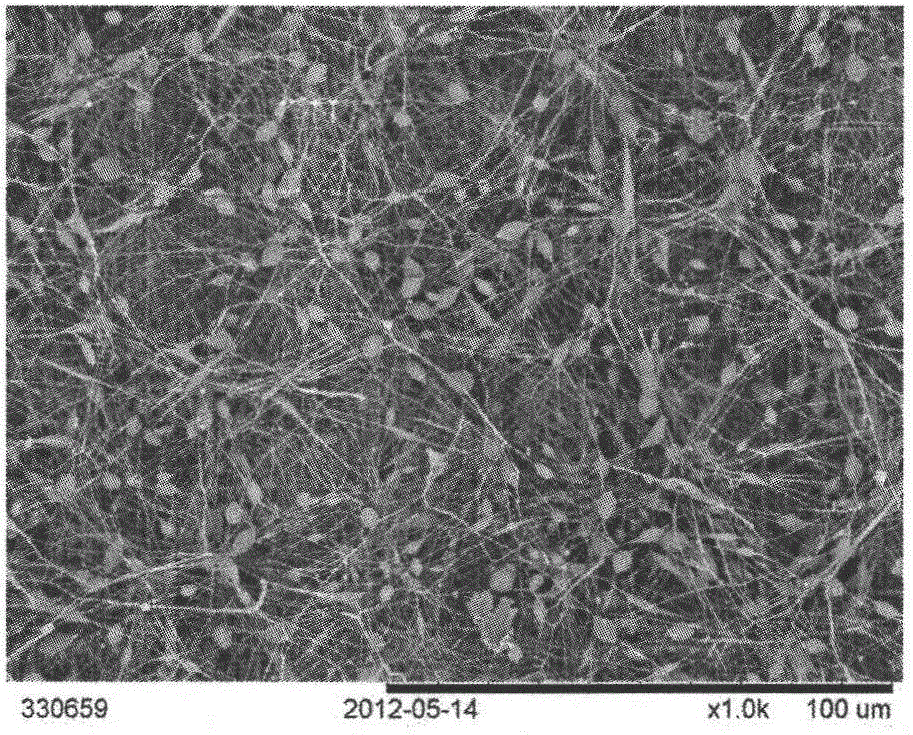

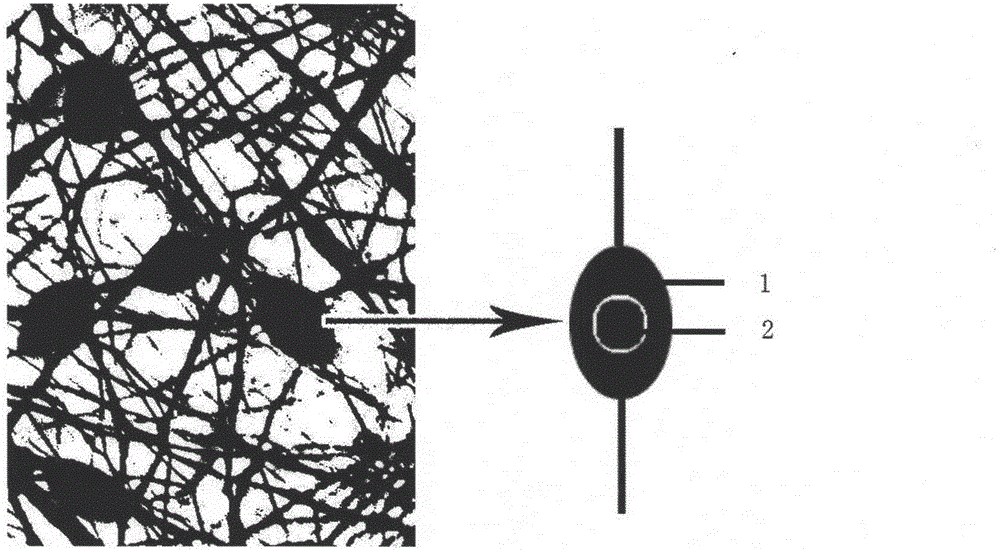

[0032] (4) The collected fiber membrane is left to dry at room temperature, and the receiver is peeled off to obtain the following: figure 1 A tissue engineering fibrous scaffold with beaded fibers loaded with protein particles is shown. Such as figure 2 As shown,...

Embodiment 2

[0036] (1) Preparation of A solution: Dissolve polylactic acid-glycolic acid copolymer in a mixed solvent of 0.25 mL N,N-dimethylformamide and 0.75 mL tetrahydrofuran to obtain A solution with a concentration of 150 mg / mL.

[0037] (2) Preparation of solution B: Add 10 mg of dextran particles loaded with bovine serum albumin with a particle size of 227-1575 nm to solution A, and stir with magnetic force at 2000 rpm for 60 min.

[0038] (3) Electrospinning: Add solution B into the syringe, spinning voltage 20kV, spinning speed 1mL / h, spinning distance 20cm, electrospinning, and collect fibers on the receiver (a metal plate covered with a layer of aluminum foil) membrane.

[0039] (4) The collected fiber membrane is left to dry at room temperature, and the receiver is peeled off to obtain a tissue engineering fiber scaffold with beaded fibers loaded with protein particles.

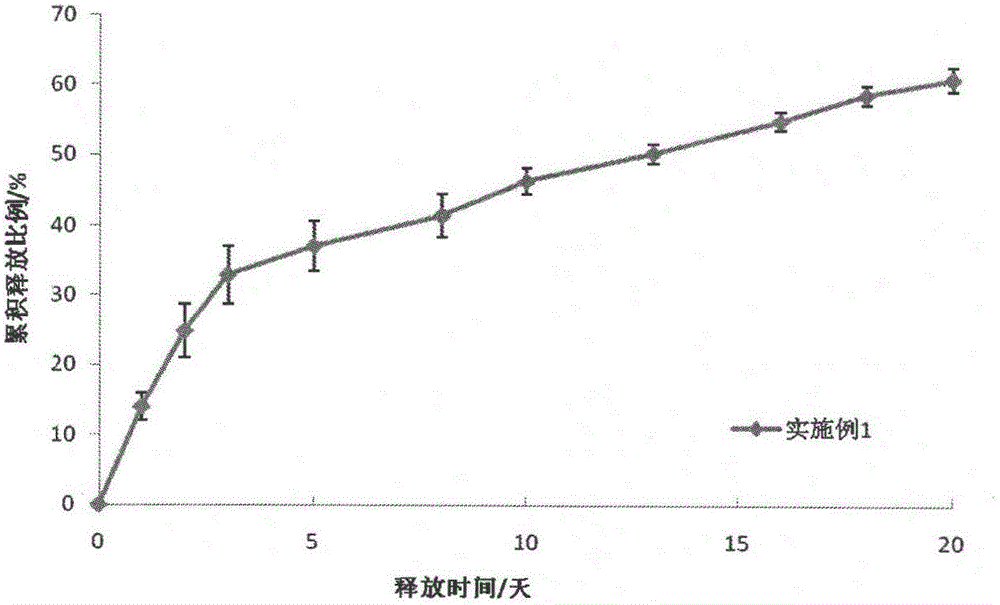

[0040] (5) Weigh 20 mg of fiber membrane, add 1 mL of PBS buffer solution with a pH of 7.4, and culture ...

Embodiment 3

[0043] (1) Preparation of A solution: Dissolve polylactic acid-glycolic acid copolymer in a mixed solvent of 0.25 mL N,N-dimethylformamide and 0.75 mL tetrahydrofuran to obtain A solution with a concentration of 150 mg / mL.

[0044] (2) Preparation of solution B: Add 6.67 mg of dextran particles loaded with bovine serum albumin with a particle size of 227-1575 nm to solution A, and stir with magnetic force at 2000 rpm for 60 min.

[0045] (3) Electrospinning: Add B solution into the syringe, set the spinning voltage to 20kV, the spinning speed to 1mL / h, and the spinning distance to 20cm, and perform electrospinning on the receiver (a metal plate covered with a layer of aluminum foil). Collect the fibrous membrane.

[0046] (4) The collected fiber membrane is left to dry at room temperature, and the receiver is peeled off to obtain a tissue engineering fiber scaffold with beaded fibers loaded with protein particles.

[0047] (5) Weigh 20mg of fiber, add 1mL of PBS buffer soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com