Catalyst with core-shell structure, and preparation method and application thereof

A core-shell structure and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic chemistry, etc., can solve the problem of metal catalytic activity decline, achieve excellent catalytic performance and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

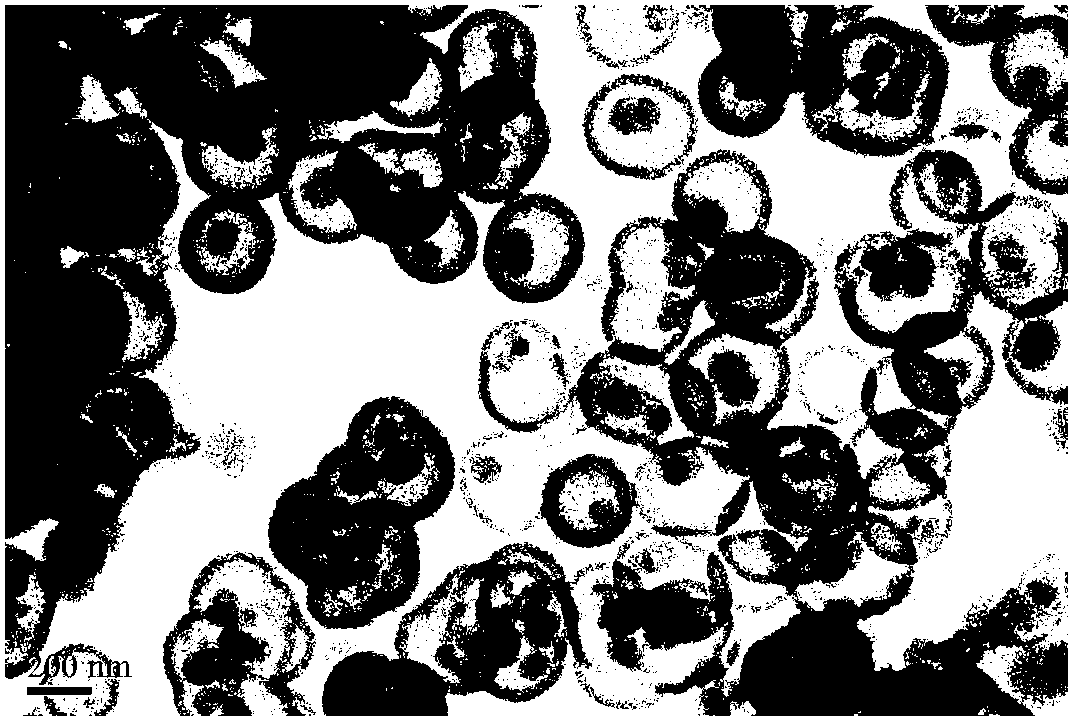

Image

Examples

Embodiment 1

[0025] (1) Add 1.6g of cetyltrimethylammonium bromide and 5.6mL of 2.0mol / L NaOH solution into 760mL of water (pH 11.5), and stir at 90°C for 1.5h. Add 8.0mL tetraethyl orthosilicate dropwise, keep stirring for 2h, let stand for 20h, filter with suction, and roast in air at 550°C for 6h to obtain a white solid; add 1.0g of the above solid to 4.4mL 0.06mol / L NH 4 RuCl 6 solution (0.264mmol), 60W ultrasonic 10min, microwave drying at 120℃ for 30min. After cooling, add 5.0 mL of 2mol / L KBH at 0°C 4 Aqueous solution (10mmol), continue to stir until no bubbles are generated, centrifuge and wash the product until neutral.

[0026] (2) Add the product obtained in step 1 into a mixed solution of 180mL ethanol and 60mL 28% ammonia water, add dropwise 0.075mL N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane, 6.0mL ethanol and a mixed solution of 6.0 mL tetraethyl orthosilicate. After stirring for 30 min, a mixed solution of 0.6 g of cetyltrimethylammonium bromide, 90 mL of ethanol and...

Embodiment 2

[0030] The catalyst described in Example 1 is applied to the reaction of starch hydrolysis-hydrogenation one-step production of sorbitol. That is: add 100mL of 10% starch aqueous solution, 0.025g metal Ru catalyst and 0.04mL glucoamylase into a 200mL reaction kettle. Fill and discharge with hydrogen 4-5 times to replace the air in the reactor, and finally control the hydrogen pressure in the reactor at 6.0MPa. The temperature was raised to 75°C for 6 hours. The reaction product was detected by liquid chromatography equipped with a Shodex sugar SC1011 chromatographic column and a differential refractive index detector. All activity data were repeated more than three times, and the error range was within 5%. The conversion rate of starch is 99%, and the yield of sorbitol is 99%.

Embodiment 3

[0032] (1) Add 1.6g of cetyltrimethylammonium bromide and 5.6mL of 2.0mol / L NaOH solution into 760mL of water, and stir at 90°C for 1.5h. After adding 8.0 mL of tetraethyl orthosilicate dropwise, keep stirring for 2 hours, let stand for 20 hours, filter with suction, and roast in air at 550°C for 6 hours to obtain a white solid. Add 1.5 g of the above solid to 4.4 mL of 0.06 mol / L NH 4 RuCl 6 In the solution, 60W ultrasonic for 10min, 120℃ microwave drying for 30min. After cooling, add 5.0 mL of 2mol / L KBH at 0°C 4 Aqueous solution, continue to stir until no bubbles are produced, centrifuge and wash the product until neutral.

[0033] (2) Add the product of step 1 into the mixed solution of 270mL ethanol and 90mL 28% ammonia water, add dropwise 0.113mL N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane, 9.0mL ethanol and 9.0mL tetraethyl orthosilicate mixed solution. After stirring for 30 min, a mixed solution of 0.9 g of cetyltrimethylammonium bromide, 135 mL of ethanol and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com