Resourced recovering and utilizing method for waste cotton fabric

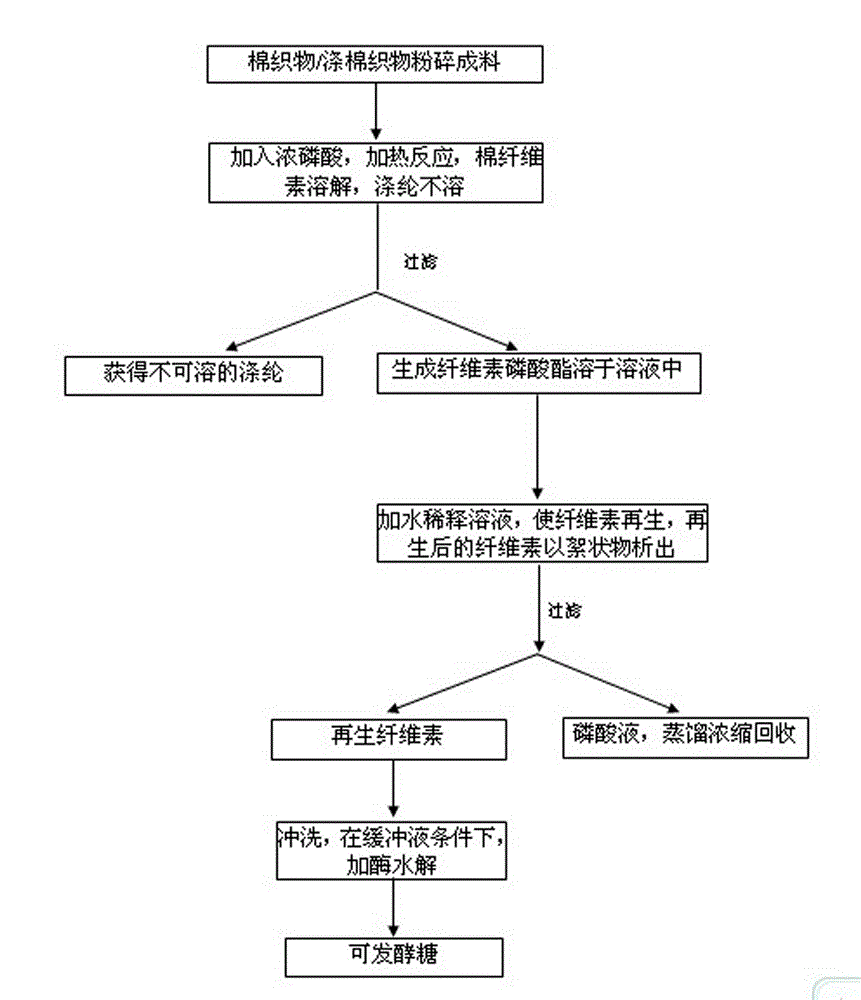

A technology for recycling cotton fabrics, applied in the field of recycling waste cotton fabrics, can solve the problems that the purity of recycled polyester cannot reach 100%, the separation of cellulose and polyester, and the separation effect is not ideal, etc., and achieves low crystallinity and environmental protection. Low pollution and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0031] Example 1: Phosphoric acid with different mass fraction concentrations is used for recycling waste cotton fabrics

[0032] (1) Raw materials

[0033] 1. Poly-cotton blend fabric, from 20 pairs of discarded jeans from different brands.

[0034] 2. Cellulase (Celluclast 1.5L) and β-glucosidase (Novozyme 188) were purchased from Novozymes.

[0035] (2) Method 1. Pulverize the mixed jeans and put them into the reactor, then add phosphoric acid with a mass fraction of 82%, 83%, and 86% into the reactor, and keep the solid-to-liquid ratio at 1: 20. Start the reaction after keeping the temperature constant at 50°C, and the reaction time is 18h.

[0036] 2. Filter the reacted solution with a 30-mesh sieve, rinse the undissolved polyester on the sieve with water, and drain the rinse and filtrate into the agitator. Dry the rinsed polyester for later use.

[0037]The main principle in the reaction process is that the cotton fiber in the raw material and concentrated phosphoric...

example 2

[0042] Example 2: Recycling of waste cotton fabrics with different phosphoric acid additions

[0043] (1) Raw materials

[0044] 1. Poly-cotton blend fabric, from 20 pairs of discarded jeans from different brands.

[0045] 2 Cellulase (Celluclast 1.5L) and β-glucosidase (Novozyme 188) were purchased from Novozymes.

[0046] (2) Method

[0047] 1. Pulverize the mixed jeans and put them into the reactor, then add phosphoric acid with a mass fraction of 85% into the reactor to make the solid-liquid ratio 1:10, 1:15, 1:30, and keep the temperature constant The reaction starts after 50°C, and the reaction time is 7h.

[0048] 2. Filter the reacted solution with a 30-mesh sieve, rinse the undissolved polyester on the sieve with water, and drain the rinse and filtrate into the agitator. Dry the rinsed polyester for later use.

[0049] 3. Add water twice the volume of phosphoric acid into the mixer and stir for 2 minutes to regenerate the cellulose. Filter the solution with a fi...

example 3

[0053] Example 3: Different reaction temperatures for waste cotton fabric recovery

[0054] (1) Raw materials

[0055] 1. Poly-cotton blend fabric, from 20 pairs of discarded jeans from different brands.

[0056] 2 Cellulase (Celluclast 1.5L) and β-glucosidase (Novozyme 188) were purchased from Novozymes.

[0057] (2) Method

[0058] 1. After the mixed jeans are pulverized by a pulverizer, put them into the reactor, and then add phosphoric acid with a mass fraction of 85% to the reactor to make the solid-liquid ratio 1:15, and keep the temperature constant at 45, 50, and 60°C Start the reaction, the reaction time is 6h.

[0059] 2. Filter the reacted solution with a 30-mesh sieve, rinse the undissolved polyester on the sieve with water, and drain the rinse and filtrate into the agitator. Dry the rinsed polyester for later use.

[0060] 3. Add water twice the volume of phosphoric acid into the mixer and stir for 2 minutes to regenerate the cellulose. Filter the solution w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com